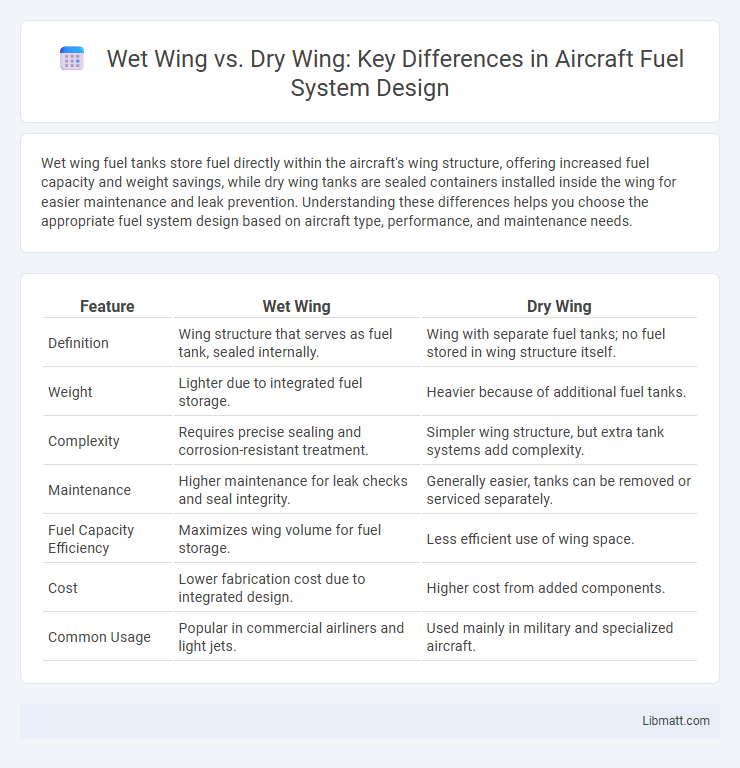

Wet wing fuel tanks store fuel directly within the aircraft's wing structure, offering increased fuel capacity and weight savings, while dry wing tanks are sealed containers installed inside the wing for easier maintenance and leak prevention. Understanding these differences helps you choose the appropriate fuel system design based on aircraft type, performance, and maintenance needs.

Table of Comparison

| Feature | Wet Wing | Dry Wing |

|---|---|---|

| Definition | Wing structure that serves as fuel tank, sealed internally. | Wing with separate fuel tanks; no fuel stored in wing structure itself. |

| Weight | Lighter due to integrated fuel storage. | Heavier because of additional fuel tanks. |

| Complexity | Requires precise sealing and corrosion-resistant treatment. | Simpler wing structure, but extra tank systems add complexity. |

| Maintenance | Higher maintenance for leak checks and seal integrity. | Generally easier, tanks can be removed or serviced separately. |

| Fuel Capacity Efficiency | Maximizes wing volume for fuel storage. | Less efficient use of wing space. |

| Cost | Lower fabrication cost due to integrated design. | Higher cost from added components. |

| Common Usage | Popular in commercial airliners and light jets. | Used mainly in military and specialized aircraft. |

Introduction to Wet Wing and Dry Wing Systems

Wet wing and dry wing systems represent two distinct aircraft fuel storage methods, where wet wings use the sealed wing structure itself as the fuel tank, while dry wings rely on separate tanks installed within or attached to the wing. Wet wing systems optimize space and reduce weight by eliminating internal tanks, enhancing fuel capacity and efficiency in commercial airliners like the Boeing 737 or Airbus A320. Dry wing systems offer ease of maintenance and leak prevention by confining fuel to dedicated tanks, commonly utilized in smaller or older aircraft models.

What is a Wet Wing?

A wet wing is an integral fuel tank design where the aircraft's wing structure itself serves as the fuel container, eliminating the need for separate fuel tanks. This design optimizes space and weight distribution, allowing fuel to be stored directly within sealed wing cavities. Understanding your aircraft's fuel system, including whether it uses a wet wing, helps ensure proper maintenance and safety during operations.

What is a Dry Wing?

A dry wing is an aircraft wing design where fuel is stored in separate, sealed tanks inside the wing structure rather than within the wing's internal cavities. This design prevents fuel from coming into direct contact with the wing's structural elements, reducing the risk of corrosion and simplifying maintenance procedures. Dry wings offer enhanced safety and easier inspection compared to wet wings, which use the wing structure itself as a fuel tank.

Key Differences Between Wet Wing and Dry Wing

Wet wing integrates fuel storage within the wing structure itself, optimizing space and reducing overall aircraft weight, while dry wing contains separate, self-sealed fuel tanks mounted inside the wing. Wet wings require careful sealing and corrosion control to prevent leaks, whereas dry wings offer easier maintenance and inspection due to accessible tank compartments. Understanding these key differences helps you evaluate aircraft design choices impacting fuel capacity, safety, and operational efficiency.

Advantages of Wet Wing Design

Wet wing design offers significant advantages including reduced overall weight by eliminating the need for separate fuel tanks, which improves aircraft fuel efficiency and payload capacity. It simplifies structural integration by using the wing's internal volume as the fuel tank, leading to cost savings in manufacturing and maintenance. Your aircraft benefits from increased usable space and enhanced fuel distribution, contributing to better performance and operational flexibility.

Advantages of Dry Wing Design

The dry wing design enhances leak prevention by isolating fuel lines within the wing structure rather than storing fuel directly in the wing. This configuration reduces corrosion risks and simplifies maintenance by allowing easier access to fuel system components. Dry wings also improve structural integrity and reduce overall aircraft weight, contributing to better fuel efficiency and performance.

Common Applications of Wet Wing vs Dry Wing

Wet wing fuel tanks are commonly found in commercial airliners and large transport aircraft due to their efficient use of wing space and reduced structural weight. Dry wing fuel tanks are predominantly used in smaller general aviation planes and military aircraft, offering easier maintenance and enhanced leak detection. Aviation manufacturers select between wet wing and dry wing designs based on aircraft size, mission requirements, and fuel capacity optimization.

Safety Considerations in Wing Fuel Storage

Wet wing fuel storage integrates fuel tanks directly into the aircraft wing structure, enhancing fuel capacity but requiring rigorous structural integrity assessments to prevent leaks and contamination. Dry wing systems utilize separate fuel tanks housed within the wings, reducing risks of fuel leaks directly impacting wing components and allowing easier maintenance access. Your choice between wet wing and dry wing fuel storage should prioritize safety by evaluating risks of fuel leakage, impact resistance, and maintenance protocols to ensure optimal fuel management and aircraft performance.

Maintenance and Durability Comparison

Wet wing fuel systems, where fuel is stored directly in the wing structure, typically require less maintenance due to fewer components such as fuel tanks and plumbing, enhancing durability by reducing leak points. Dry wing systems use removable fuel tanks within the wings, which can simplify inspections and repairs but may introduce additional seals and fittings that increase maintenance needs and potential wear. Your choice between wet and dry wing designs impacts ongoing upkeep and long-term reliability, with wet wings offering streamlined maintenance but dry wings providing easier access for repairs.

Choosing the Right Wing System for Your Aircraft

Wet wing fuel systems integrate fuel storage directly into the wing structure, maximizing fuel capacity without adding extra tanks, ideal for aircraft requiring high efficiency and weight savings. Dry wing systems use sealed, removable fuel tanks located within the wing, simplifying maintenance and inspection, making them preferable for aircraft with frequent servicing or modification needs. Selecting the appropriate wing system depends on factors such as aircraft design, fuel capacity requirements, maintenance preferences, and operational efficiency priorities.

Wet wing vs Dry wing Infographic

libmatt.com

libmatt.com