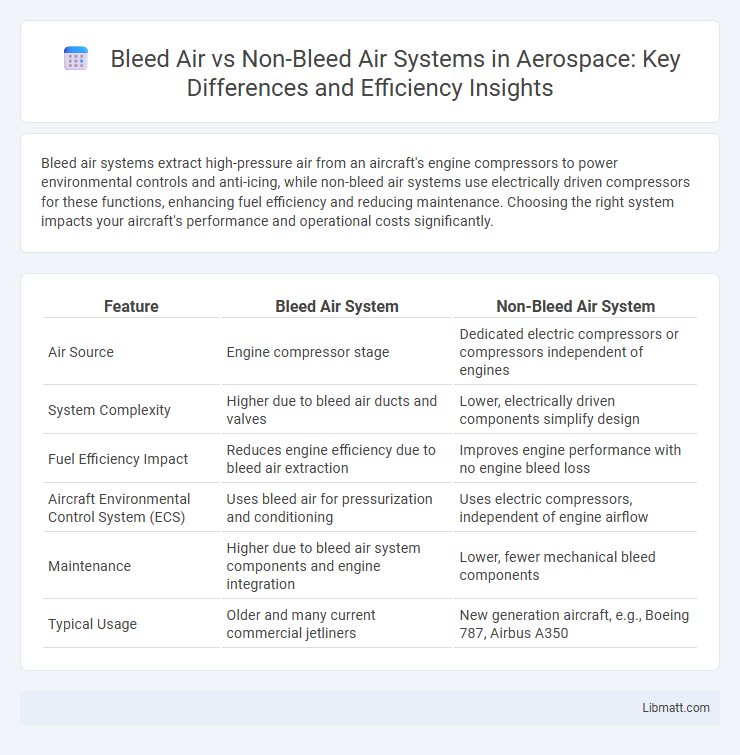

Bleed air systems extract high-pressure air from an aircraft's engine compressors to power environmental controls and anti-icing, while non-bleed air systems use electrically driven compressors for these functions, enhancing fuel efficiency and reducing maintenance. Choosing the right system impacts your aircraft's performance and operational costs significantly.

Table of Comparison

| Feature | Bleed Air System | Non-Bleed Air System |

|---|---|---|

| Air Source | Engine compressor stage | Dedicated electric compressors or compressors independent of engines |

| System Complexity | Higher due to bleed air ducts and valves | Lower, electrically driven components simplify design |

| Fuel Efficiency Impact | Reduces engine efficiency due to bleed air extraction | Improves engine performance with no engine bleed loss |

| Aircraft Environmental Control System (ECS) | Uses bleed air for pressurization and conditioning | Uses electric compressors, independent of engine airflow |

| Maintenance | Higher due to bleed air system components and engine integration | Lower, fewer mechanical bleed components |

| Typical Usage | Older and many current commercial jetliners | New generation aircraft, e.g., Boeing 787, Airbus A350 |

Introduction to Bleed Air and Non-Bleed Air Systems

Bleed air systems extract compressed air from an aircraft engine's compressor section to power various functions such as cabin pressurization, air conditioning, and anti-icing. In contrast, non-bleed air systems utilize electrically driven compressors and environmental control systems, eliminating reliance on engine bleed air and improving fuel efficiency. Understanding the differences between bleed air and non-bleed air systems helps optimize your aircraft's performance and maintenance strategy.

How Bleed Air Systems Work

Bleed air systems extract high-pressure, high-temperature air from an aircraft engine's compressor stage and channel it through ducts to supply cabin pressurization, air conditioning, and anti-icing systems. This air undergoes cooling and filtering before being distributed to various subsystems, ensuring efficient environmental control within the aircraft. In contrast, non-bleed air systems use electrically driven compressors to provide conditioned air without tapping into engine compressor stages, enhancing fuel efficiency and reducing maintenance complexity.

Understanding Non-Bleed Air Technology

Non-bleed air technology eliminates the traditional practice of extracting compressed air from jet engine compressors, improving fuel efficiency and reducing maintenance due to lower system complexity. This system uses electrically driven compressors and environmental control systems, enhancing aircraft performance and sustainability. Understanding non-bleed air technology allows you to appreciate advancements in modern aerospace design that prioritize efficiency and reduced environmental impact.

Key Differences Between Bleed Air and Non-Bleed Air

Bleed air systems extract compressed air from aircraft engines to power various pneumatic functions, while non-bleed air systems utilize electrically driven compressors or motor-driven air cycle machines, enhancing fuel efficiency by reducing engine load. Bleed air is typically sourced from engine compressor stages, which can affect engine performance and increase maintenance complexity, whereas non-bleed air systems integrate advanced electrical architecture, minimizing bleed air dependency and improving system reliability. Your choice between bleed air and non-bleed air impacts aircraft design, operational efficiency, and maintenance procedures, reflecting modern trends toward electrically powered environmental control systems.

Advantages of Bleed Air Systems

Bleed air systems in aircraft provide a reliable source of high-pressure, high-temperature air directly from the engine compressor stages, enabling efficient cabin pressurization, air conditioning, and anti-icing functions without the need for additional compressors. These systems reduce aircraft weight and complexity by utilizing existing engine airflow, allowing for more straightforward maintenance and improved fuel efficiency. Your aircraft benefits from proven performance and safety standards due to the mature technology and widespread adoption of bleed air systems in commercial aviation.

Benefits of Non-Bleed Air Systems

Non-bleed air systems enhance engine efficiency by eliminating the need to divert compressed air for cabin pressurization and air conditioning, resulting in improved fuel economy and reduced emissions. These systems reduce maintenance complexity and weight since they avoid traditional bleed air ducts and valves, lowering operational costs and increasing reliability. Improved cabin air quality is another advantage, as non-bleed air systems often use electrically driven compressors, minimizing contamination risks associated with bleed air sources.

Efficiency and Performance Comparison

Bleed air systems extract compressed air from the engine, which can reduce engine efficiency and fuel economy by diverting power away from thrust production. Non-bleed air systems, typically used in more modern aircraft like the Boeing 787, improve overall performance by utilizing electrically powered compressors, enhancing fuel efficiency and reducing maintenance needs. Your choice between the two can impact operational costs and environmental performance, with non-bleed air systems generally offering superior efficiency and aircraft performance.

Impact on Aircraft Maintenance and Reliability

Bleed air systems, which extract compressed air from engine compressors, often lead to increased aircraft maintenance due to potential contamination and wear of pneumatic components, affecting overall reliability. Non-bleed air systems, such as those using electrically driven compressors, reduce mechanical complexity and contamination risks, enhancing maintenance efficiency and system reliability. Transitioning to non-bleed air technology decreases the frequency of pneumatic system inspections and the likelihood of in-flight air supply failures.

Environmental Considerations and Fuel Efficiency

Bleed air systems, which extract high-pressure air from the engine compressor, often reduce overall fuel efficiency due to the additional energy required to compress and divert this air, leading to increased fuel consumption and carbon emissions. Non-bleed air systems improve fuel efficiency by eliminating the need for bleed air extraction, allowing engines to operate at optimized performance levels and reduce greenhouse gas emissions. Environmental considerations favor non-bleed air systems as they contribute to lower noise pollution and decreased nitrogen oxide (NOx) emissions, aligning with stricter international aviation environmental regulations.

Future Trends in Aircraft Air System Technologies

Future trends in aircraft air system technologies emphasize increased adoption of non-bleed air systems to improve fuel efficiency and reduce maintenance costs by eliminating the need to extract compressed air from engines. Advances in electrically driven compressors and environmental control systems (ECS) allow non-bleed air systems to provide cleaner, more reliable cabin air without affecting engine performance. Your aircraft's air system is likely to become more energy-efficient and environmentally friendly as manufacturers continue to innovate beyond traditional bleed air methods.

Bleed air vs Non-bleed air Infographic

libmatt.com

libmatt.com