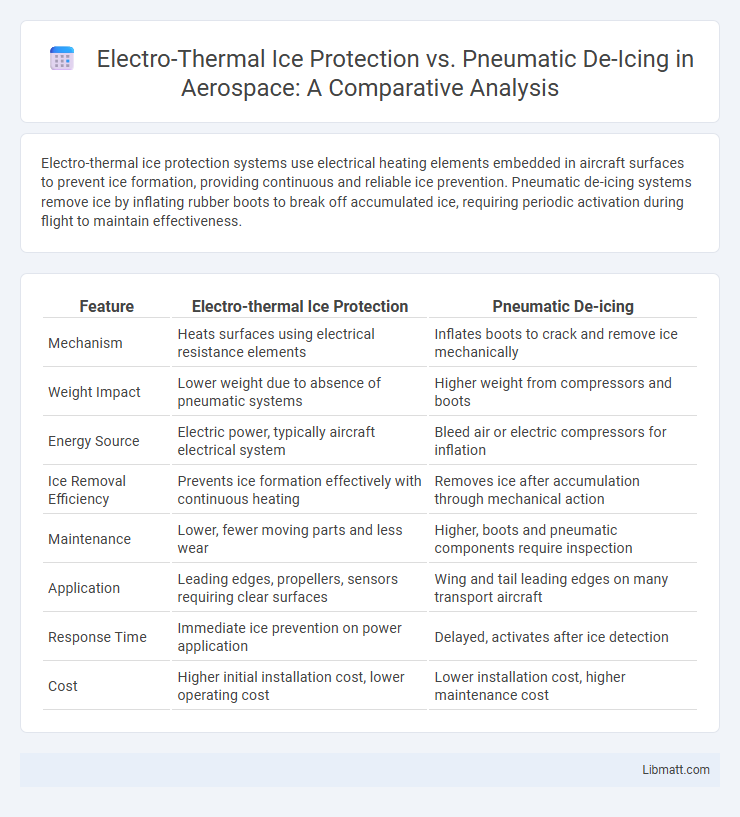

Electro-thermal ice protection systems use electrical heating elements embedded in aircraft surfaces to prevent ice formation, providing continuous and reliable ice prevention. Pneumatic de-icing systems remove ice by inflating rubber boots to break off accumulated ice, requiring periodic activation during flight to maintain effectiveness.

Table of Comparison

| Feature | Electro-thermal Ice Protection | Pneumatic De-icing |

|---|---|---|

| Mechanism | Heats surfaces using electrical resistance elements | Inflates boots to crack and remove ice mechanically |

| Weight Impact | Lower weight due to absence of pneumatic systems | Higher weight from compressors and boots |

| Energy Source | Electric power, typically aircraft electrical system | Bleed air or electric compressors for inflation |

| Ice Removal Efficiency | Prevents ice formation effectively with continuous heating | Removes ice after accumulation through mechanical action |

| Maintenance | Lower, fewer moving parts and less wear | Higher, boots and pneumatic components require inspection |

| Application | Leading edges, propellers, sensors requiring clear surfaces | Wing and tail leading edges on many transport aircraft |

| Response Time | Immediate ice prevention on power application | Delayed, activates after ice detection |

| Cost | Higher initial installation cost, lower operating cost | Lower installation cost, higher maintenance cost |

Introduction to Aircraft Ice Protection Systems

Aircraft ice protection systems are essential for maintaining flight safety by preventing ice accumulation on critical surfaces. Electro-thermal ice protection utilizes electrical heating elements embedded in wing leading edges to melt ice continuously, providing efficient and consistent de-icing during flight. Pneumatic de-icing employs inflatable boots that mechanically break and shed ice, offering a reliable solution but requiring periodic activation to clear ice buildup.

Understanding Electro-thermal Ice Protection

Electro-thermal ice protection systems utilize electrical resistance heaters embedded in aircraft surfaces to prevent ice formation by generating heat directly on critical areas like wings and engine inlets. These systems offer precise temperature control, reducing power consumption while maintaining aerodynamic efficiency and minimizing structural stress. Unlike pneumatic de-icing boots that rely on mechanical inflation to shed ice, electro-thermal solutions provide continuous protection and improved reliability in diverse icing conditions.

Overview of Pneumatic De-icing Systems

Pneumatic de-icing systems use inflatable boots installed on leading edges of aircraft wings and tail surfaces to mechanically break and shed accumulated ice. These systems rapidly inflate and deflate rubber boots to crack ice formations, ensuring critical surfaces remain aerodynamically efficient. Your aircraft benefits from this reliable, low-maintenance method, commonly favored for smaller aircraft and short-haul flights.

Key Differences: Electro-thermal vs Pneumatic Methods

Electro-thermal ice protection uses embedded heating elements to prevent ice accumulation by continuously raising surface temperature, offering precise and energy-efficient ice management. Pneumatic de-icing relies on inflatable boots that mechanically expand and break ice layers after buildup, providing only reactive ice removal rather than prevention. Your choice between these methods depends on aircraft design priorities such as weight, energy consumption, and the need for continuous versus intermittent ice control.

Performance and Efficiency Comparison

Electro-thermal ice protection systems provide consistent and rapid heating directly to critical aircraft surfaces, ensuring efficient ice melting with minimal energy waste. Pneumatic de-icing boots rely on inflatable bladders to mechanically shed ice, which can cause intermittent protection and slower response times during flight. Your choice between these systems impacts overall aircraft performance, as electro-thermal solutions offer better energy efficiency and continuous ice prevention compared to the periodic activation required by pneumatic boots.

Installation and Maintenance Considerations

Electro-thermal ice protection systems require complex electrical wiring and integration with an aircraft's power supply, demanding skilled installation and regular system diagnostics to ensure consistent heating performance. Pneumatic de-icing boots involve mechanically installed inflatable rubber sheets on leading edges, which necessitate periodic inspection for leaks, wear, and proper inflation cycles, typically resulting in more straightforward maintenance procedures. Maintenance of electro-thermal systems often involves electronic component testing and potential replacements, while pneumatic systems focus on the durability and sealing of the boots, influencing overall operational costs and downtime.

Energy Consumption and Operational Costs

Electro-thermal ice protection systems consume electrical energy continuously to prevent ice formation, leading to higher energy usage but lower mechanical complexity and maintenance needs. Pneumatic de-icing boots use compressed air only during ice shedding cycles, resulting in intermittent energy consumption but increased operational costs due to air compressor wear and system maintenance. Your choice between these technologies impacts operational efficiency, with electro-thermal systems typically incurring higher energy costs but lower maintenance expenses compared to pneumatic de-icing boots.

Safety and Reliability Factors

Electro-thermal ice protection systems provide consistent and rapid heating directly to critical aircraft surfaces, ensuring continuous ice prevention and enhancing flight safety in severe weather conditions. Pneumatic de-icing boots rely on mechanical inflation to break ice accumulation but may allow ice buildup between cycles, potentially compromising reliability during prolonged icing events. Your aircraft's safety benefits from the stable and proactive nature of electro-thermal systems, which deliver precise temperature control and reduce the risk of ice shedding hazards compared to the intermittent function of pneumatic boots.

Suitability for Different Aircraft Types

Electro-thermal ice protection systems are well-suited for smaller to medium-sized aircraft due to their lightweight design and efficient energy use, making them ideal for regional jets and turboprops. Pneumatic de-icing boots are commonly found on larger, older commercial and general aviation aircraft where robust mechanical reliability outweighs weight concerns. Your choice depends on aircraft size, operational environment, and maintenance preferences to ensure optimal anti-icing performance.

Future Trends in Ice Protection Technologies

Electro-thermal ice protection systems leverage advanced conductive materials and precise thermal control, showing promising improvements in energy efficiency and system weight reduction for aerospace applications. Pneumatic de-icing technology, relying on inflatable boots, is evolving with smarter sensors and adaptive inflation algorithms to enhance responsiveness and reliability. Your aircraft's future ice protection will likely integrate hybrid systems combining electro-thermal elements with pneumatic components, optimizing safety and performance in varied icing conditions.

Electro-thermal Ice Protection vs Pneumatic De-icing Infographic

libmatt.com

libmatt.com