Load factor represents the ratio of actual applied load to the designed load capacity, ensuring structures operate within safe limits. Limit load is the maximum load a structure can withstand before permanent deformation occurs, critical for maintaining Your system's integrity and safety.

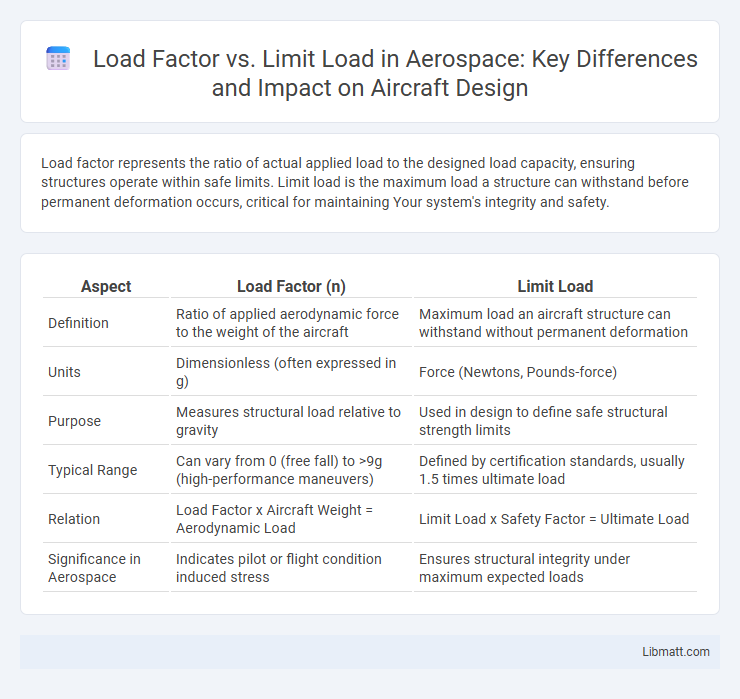

Table of Comparison

| Aspect | Load Factor (n) | Limit Load |

|---|---|---|

| Definition | Ratio of applied aerodynamic force to the weight of the aircraft | Maximum load an aircraft structure can withstand without permanent deformation |

| Units | Dimensionless (often expressed in g) | Force (Newtons, Pounds-force) |

| Purpose | Measures structural load relative to gravity | Used in design to define safe structural strength limits |

| Typical Range | Can vary from 0 (free fall) to >9g (high-performance maneuvers) | Defined by certification standards, usually 1.5 times ultimate load |

| Relation | Load Factor x Aircraft Weight = Aerodynamic Load | Limit Load x Safety Factor = Ultimate Load |

| Significance in Aerospace | Indicates pilot or flight condition induced stress | Ensures structural integrity under maximum expected loads |

Introduction to Load Factor and Limit Load

Load Factor is a safety multiplier applied to the nominal load of a structure to ensure it can withstand unexpected stresses without failure. Limit Load represents the maximum load a structure can endure before plastic deformation or collapse occurs. Understanding the distinction between Load Factor and Limit Load helps you design safer and more reliable engineering systems.

Definitions: Load Factor vs Limit Load

Load Factor represents the ratio of the actual applied load on a structure to the maximum expected or design load, indicating the margin of safety incorporated in engineering designs. Limit Load is the maximum load a structure can withstand before experiencing permanent deformation or failure, defining the threshold for structural integrity. Understanding the distinction between Load Factor and Limit Load is critical in ensuring safety and reliability in structural engineering and design.

Importance in Structural Engineering

Load factor and limit load are critical concepts in structural engineering that ensure safety and reliability in design. Load factor represents a multiplier applied to service loads to account for uncertainties and variability in actual conditions, while limit load defines the maximum load a structure can withstand before failure. Understanding these parameters helps you optimize material use while preventing structural collapse under extreme stress.

The Role of Load Factor in Design

The Load Factor plays a critical role in structural design by providing a safety margin above the Limit Load, which is the maximum expected load a structure can withstand without failure. It ensures Your design can accommodate unexpected variations in loads, material imperfections, and other uncertainties, enhancing overall reliability and safety. By applying appropriate Load Factors, engineers can prevent structural collapse and extend the service life of buildings and infrastructure.

Understanding Limit Load Capacity

Limit load capacity represents the maximum load a structure can withstand without experiencing permanent deformation or failure, serving as a critical safety threshold in engineering design. Load factor is applied to the expected loads to ensure that the structure's limit load capacity is not exceeded under uncertain or extreme conditions. Understanding your system's limit load capacity allows you to design safer structures that prevent catastrophic failure while optimizing material usage.

Key Differences Between Load Factor and Limit Load

Load factor refers to the ratio of the actual load applied on a structure to its design load, indicating the level of stress experienced during operation. Limit load represents the maximum load a structure can withstand without undergoing permanent deformation or failure, defined by material strength and structural capacity. The key difference lies in load factor being a measure of operational stress relative to design parameters, while limit load dictates the ultimate threshold beyond which structural integrity is compromised.

Application in Safety Assessments

Load factor and limit load play critical roles in safety assessments by ensuring structures withstand applied stresses without failure. Load factor is a multiplier applied to design loads to provide a safety margin, while limit load represents the maximum load a structure can endure before permanent deformation occurs. Your safety evaluations rely on accurately comparing factored loads against the limit load to prevent structural collapse and ensure reliability in engineering designs.

Calculating Load Factor and Limit Load

Calculating Load Factor involves dividing the actual applied load by the allowable load to determine the safety margin of a structure or system. Limit Load is calculated by identifying the maximum load a structure can support without experiencing permanent deformation or failure, often derived from material yield strength and cross-sectional area. Understanding the relationship between Load Factor and Limit Load ensures accurate assessment of structural performance and safety under various loading conditions.

Real-World Examples and Case Studies

Load factor in engineering measures the ratio of actual load to design limit load, influencing structural safety margins in real-world applications such as bridge construction where dynamic vehicular weights are considered. Case studies in aerospace highlight how limit load defines the maximum expected stress during flight, with load factor ensuring operational loads remain within safe bounds under turbulence. These examples demonstrate the critical balance between load factor and limit load for preventing structural failures in high-stakes environments.

Best Practices for Engineers

Engineers should prioritize accurate calculation of load factor and limit load to ensure structural safety and compliance with industry standards like ASME and FAA regulations. Employing real-time monitoring technologies and finite element analysis (FEA) enhances precision in predicting load effects and identifying potential failure points. Regular validation through testing and conservative design margins ensures reliability under variable operating conditions.

Load Factor vs Limit Load Infographic

libmatt.com

libmatt.com