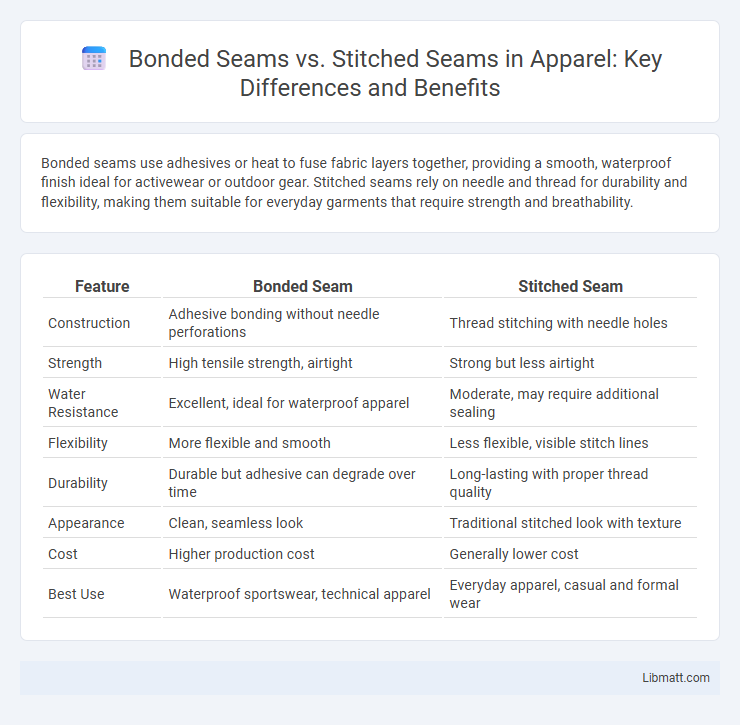

Bonded seams use adhesives or heat to fuse fabric layers together, providing a smooth, waterproof finish ideal for activewear or outdoor gear. Stitched seams rely on needle and thread for durability and flexibility, making them suitable for everyday garments that require strength and breathability.

Table of Comparison

| Feature | Bonded Seam | Stitched Seam |

|---|---|---|

| Construction | Adhesive bonding without needle perforations | Thread stitching with needle holes |

| Strength | High tensile strength, airtight | Strong but less airtight |

| Water Resistance | Excellent, ideal for waterproof apparel | Moderate, may require additional sealing |

| Flexibility | More flexible and smooth | Less flexible, visible stitch lines |

| Durability | Durable but adhesive can degrade over time | Long-lasting with proper thread quality |

| Appearance | Clean, seamless look | Traditional stitched look with texture |

| Cost | Higher production cost | Generally lower cost |

| Best Use | Waterproof sportswear, technical apparel | Everyday apparel, casual and formal wear |

Introduction to Bonded and Stitched Seams

Bonded seams use adhesives or heat to fuse fabric layers together, providing a smooth, lightweight finish ideal for sportswear and performance garments. Stitched seams involve sewing fabric pieces with thread, offering durability and traditional construction often used in casual and heavy-duty apparel. Choosing between bonded and stitched seams depends on the desired strength, flexibility, and garment application.

What is a Bonded Seam?

A bonded seam is a type of seam where two fabric edges are joined together using adhesive materials, heat, or ultrasonic welding instead of traditional stitching. This method creates a smooth, flat finish that enhances waterproofing, durability, and aesthetic appeal, commonly used in performance wear and technical textiles. Bonded seams eliminate needle holes, reducing potential points of water infiltration compared to stitched seams, making them ideal for outdoor and active apparel.

What is a Stitched Seam?

A stitched seam is created by sewing two pieces of fabric together using thread, forming a durable and flexible bond commonly used in garments and outdoor gear. This technique provides strength and allows for various stitch patterns to enhance garment fit and durability. Your choice between stitched and bonded seams depends on the desired flexibility, strength, and appearance of the finished product.

Key Differences: Bonded vs Stitched Seams

Bonded seams use adhesive materials to join fabric edges, creating a smooth, waterproof finish ideal for performance wear and outdoor gear, while stitched seams rely on thread and needle techniques to combine fabric layers, offering greater flexibility and traditional durability. Bonded seams reduce bulk and prevent water penetration, making them superior for lightweight and technical garments; stitched seams, however, provide stronger mechanical strength and easier repairability. The choice between bonded and stitched seams depends on the requirements for breathability, strength, aesthetics, and garment function.

Material Compatibility for Each Seam Type

Bonded seams work best with thermoplastic materials such as polyester or nylon, where heat and adhesives create a strong, waterproof bond without puncturing the fabric. Stitched seams provide versatility, accommodating a wide range of materials including cotton, denim, leather, and synthetic fabrics, but may require seam sealing for water resistance. Material compatibility is a key factor in seam selection, as bonded seams rely on fabric fusion, while stitched seams depend on thread strength and fabric punch resistance.

Strength and Durability Comparison

Bonded seams use adhesives or heat to fuse materials, offering a smooth finish with strong resistance to water and wind penetration, making them ideal for performance gear requiring lightweight durability. Stitched seams rely on thread penetration, providing high mechanical strength and flexibility but may be prone to water ingress and wear over time, especially if not sealed. For maximum durability and strength, bonded seams excel in maintaining integrity under stress without thread degradation, while stitched seams offer reliable tensile strength but require additional sealing for enhanced moisture protection.

Waterproofing and Weather Resistance

Bonded seams provide superior waterproofing and weather resistance by using adhesive to create a continuous barrier that prevents water penetration, making them ideal for outdoor gear and rainwear exposed to harsh conditions. Stitched seams, while durable, have tiny holes from needle punctures that can allow water ingress, often requiring additional seam sealing treatments to enhance weatherproofing. For optimal performance in wet environments, bonded seams reduce the risk of leaks and improve garment longevity compared to traditional stitched seams.

Aesthetic and Design Considerations

Bonded seams provide a sleek, smooth finish that enhances modern, minimalist garment designs by eliminating visible stitching lines. Stitched seams offer a traditional, textured look that can add decorative detail and emphasize craftsmanship in apparel. Designers choose bonded seams for clean, advanced aesthetics and stitched seams when visual seam definition complements the garment's style.

Cost Implications and Production Efficiency

Bonded seams generally reduce labor costs and increase production speed by eliminating the need for traditional stitching, making them more cost-effective for high-volume manufacturing. Stitched seams, while often requiring more time and skilled labor, provide greater durability and flexibility, which can lead to longer product life and potentially lower replacement costs. Your choice between bonded and stitched seams should balance upfront cost savings with the long-term performance requirements of the garment or product.

Best Applications for Bonded and Stitched Seams

Bonded seams are best suited for applications requiring waterproof, airtight, and highly durable finishes, such as outdoor gear, sportswear, and medical textiles, where minimizing bulk and enhancing flexibility are critical. Stitched seams are ideal for traditional apparel, upholstery, and heavy-duty items where strength and repairability are prioritized, often allowing for easier adjustments and alterations. Your choice depends on the specific performance needs and end-use environment of the fabric product.

bonded seam vs stitched seam Infographic

libmatt.com

libmatt.com