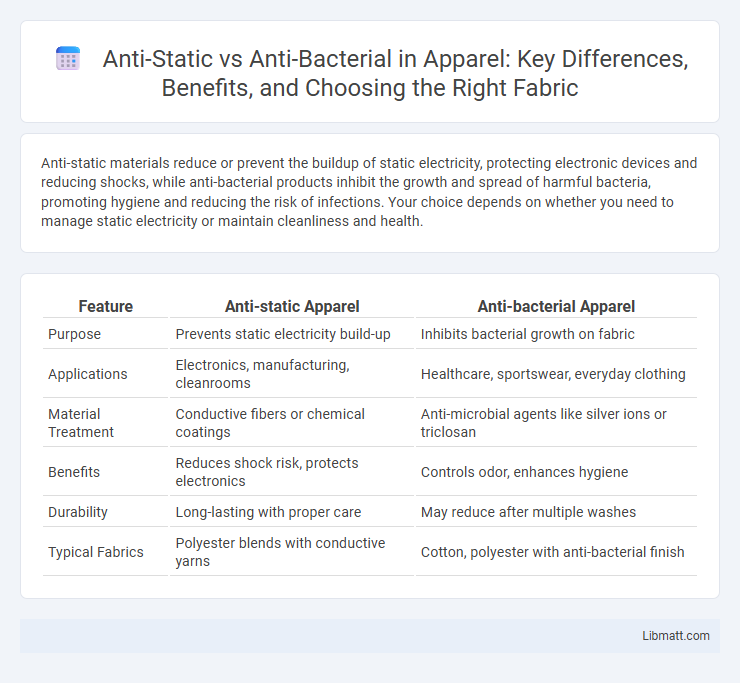

Anti-static materials reduce or prevent the buildup of static electricity, protecting electronic devices and reducing shocks, while anti-bacterial products inhibit the growth and spread of harmful bacteria, promoting hygiene and reducing the risk of infections. Your choice depends on whether you need to manage static electricity or maintain cleanliness and health.

Table of Comparison

| Feature | Anti-static Apparel | Anti-bacterial Apparel |

|---|---|---|

| Purpose | Prevents static electricity build-up | Inhibits bacterial growth on fabric |

| Applications | Electronics, manufacturing, cleanrooms | Healthcare, sportswear, everyday clothing |

| Material Treatment | Conductive fibers or chemical coatings | Anti-microbial agents like silver ions or triclosan |

| Benefits | Reduces shock risk, protects electronics | Controls odor, enhances hygiene |

| Durability | Long-lasting with proper care | May reduce after multiple washes |

| Typical Fabrics | Polyester blends with conductive yarns | Cotton, polyester with anti-bacterial finish |

Understanding Anti-Static and Anti-Bacterial Properties

Anti-static properties prevent the buildup of static electricity by dissipating electrical charges on surfaces, making materials safer and more comfortable in electronic and industrial applications. Anti-bacterial properties inhibit the growth and spread of bacteria on surfaces, promoting hygiene and reducing the risk of infections in healthcare and everyday environments. Understanding the difference helps you choose materials suited to either minimizing static or enhancing cleanliness depending on your needs.

How Anti-Static Solutions Work

Anti-static solutions work by neutralizing or dissipating static electricity buildup on surfaces through conductive or dissipative materials that prevent static discharge. These solutions often include coatings, sprays, or additives that create a path for static charges to safely discharge, protecting sensitive electronics and reducing dust attraction. You can enhance your equipment's longevity and performance by choosing the right anti-static product tailored to your environment.

Mechanisms Behind Anti-Bacterial Treatments

Anti-bacterial treatments use chemical agents or coatings that disrupt bacterial cell walls, inhibit protein synthesis, or interfere with microbial DNA replication to prevent bacterial growth and proliferation. These mechanisms involve active ingredients such as silver ions, triclosan, or quaternary ammonium compounds that target specific cellular functions essential for bacteria survival. Understanding these processes helps you choose effective products that reduce bacterial contamination on surfaces or textiles.

Key Differences Between Anti-Static and Anti-Bacterial Products

Anti-static products are designed to reduce or eliminate the buildup of static electricity, commonly used in electronic manufacturing and cleanroom environments, while anti-bacterial products specifically target the reduction or elimination of bacteria to prevent infections and maintain hygiene. The primary difference lies in their function: anti-static materials control electrical charges, whereas anti-bacterial products inhibit microbial growth. Understanding these distinctions helps you choose the right product for your specific needs, whether managing electronics or ensuring sanitary conditions.

Applications of Anti-Static Materials

Anti-static materials are widely used in electronic manufacturing, clean rooms, and industries handling sensitive components to prevent electrostatic discharge that can damage equipment. These materials also find applications in packaging for electronic devices, industrial flooring, and wearable fabrics to enhance safety and performance. Your choice of anti-static materials ensures protection of delicate electronics and smooth operation in environments vulnerable to static electricity.

Common Uses for Anti-Bacterial Surfaces

Anti-bacterial surfaces are commonly used in healthcare settings, food preparation areas, and public transportation to inhibit the growth of harmful bacteria and reduce the risk of infections. These surfaces are essential in hospitals for surgical instruments, patient rooms, and medical devices to maintain sterile environments. In kitchens and restaurants, anti-bacterial coatings on countertops and utensils help ensure food safety by preventing bacterial contamination.

Benefits of Anti-Static Versus Anti-Bacterial

Anti-static materials reduce the buildup of static electricity, preventing damage to sensitive electronic components and reducing dust attraction on surfaces. Anti-bacterial products inhibit the growth of bacteria, promoting hygiene and reducing the risk of infections in medical and everyday environments. Choosing between anti-static and anti-bacterial features depends on the application, with anti-static ideal for electronics and anti-bacterial essential for health-related settings.

Choosing the Right Solution: Anti-Static or Anti-Bacterial

Choosing the right solution depends on the specific environmental hazards and product application; anti-static treatments prevent the buildup of static electricity in electronics and sensitive equipment, while anti-bacterial coatings inhibit microbial growth on surfaces to promote hygiene. Industries like electronics manufacturing benefit more from anti-static solutions to protect components, whereas healthcare and food processing require anti-bacterial properties to reduce contamination risks. Proper assessment of the operating environment and targeted risks ensures selection of an optimal solution for maintaining safety and product integrity.

Industry Standards and Certifications

Anti-static materials comply with industry standards such as ANSI/ESD S20.20, ensuring protection against electrostatic discharge in electronic manufacturing environments. Anti-bacterial products must meet certifications like ISO 22196 or EPA registration, verifying their effectiveness in inhibiting microbial growth on surfaces. Your choice between anti-static and anti-bacterial solutions should align with specific industry certification requirements relevant to your application.

Future Trends in Surface Protection Technologies

Future trends in surface protection technologies emphasize the integration of anti-static and anti-bacterial properties to enhance hygiene and safety in various industries. Innovations in nanomaterials enable surfaces to simultaneously resist static electricity and inhibit microbial growth, offering comprehensive protection. Your environment benefits from these advancements through improved durability and reduced contamination risks.

Anti-static vs anti-bacterial Infographic

libmatt.com

libmatt.com