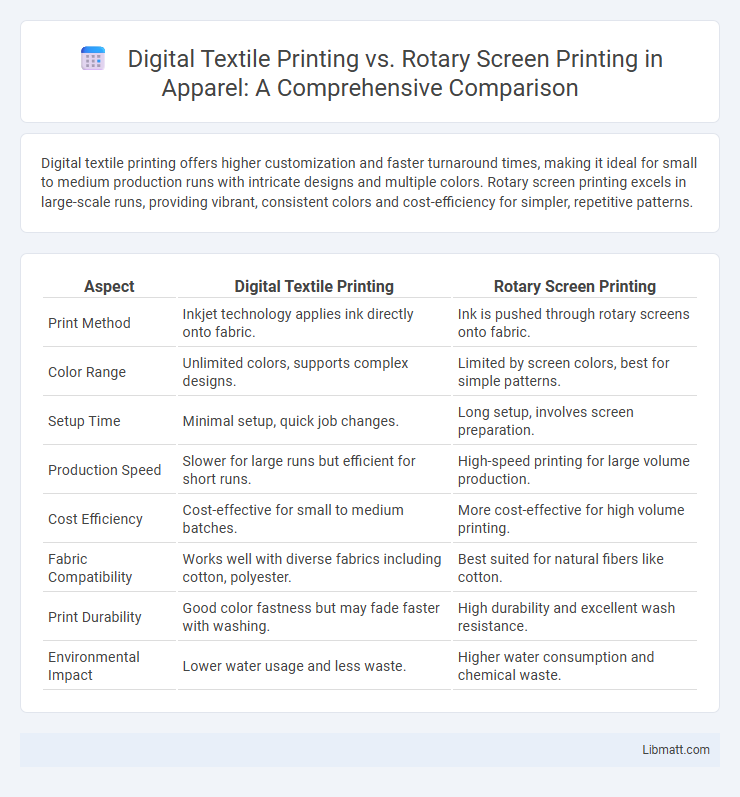

Digital textile printing offers higher customization and faster turnaround times, making it ideal for small to medium production runs with intricate designs and multiple colors. Rotary screen printing excels in large-scale runs, providing vibrant, consistent colors and cost-efficiency for simpler, repetitive patterns.

Table of Comparison

| Aspect | Digital Textile Printing | Rotary Screen Printing |

|---|---|---|

| Print Method | Inkjet technology applies ink directly onto fabric. | Ink is pushed through rotary screens onto fabric. |

| Color Range | Unlimited colors, supports complex designs. | Limited by screen colors, best for simple patterns. |

| Setup Time | Minimal setup, quick job changes. | Long setup, involves screen preparation. |

| Production Speed | Slower for large runs but efficient for short runs. | High-speed printing for large volume production. |

| Cost Efficiency | Cost-effective for small to medium batches. | More cost-effective for high volume printing. |

| Fabric Compatibility | Works well with diverse fabrics including cotton, polyester. | Best suited for natural fibers like cotton. |

| Print Durability | Good color fastness but may fade faster with washing. | High durability and excellent wash resistance. |

| Environmental Impact | Lower water usage and less waste. | Higher water consumption and chemical waste. |

Introduction to Digital Textile Printing and Rotary Screen Printing

Digital textile printing uses inkjet technology to directly apply designs onto fabrics with high precision and vibrant color accuracy, allowing for complex and customizable patterns. Rotary screen printing employs cylindrical screens to transfer dye onto textiles through mechanical rotation, excelling in large-volume production with consistent color application. Each method offers distinct advantages in terms of production speed, detail resolution, and fabric compatibility.

Key Differences Between Digital and Rotary Screen Printing

Digital textile printing offers precision and customization with the ability to produce intricate designs directly onto fabric using inkjet technology, ideal for small to medium runs. Rotary screen printing utilizes cylindrical screens to apply dye in continuous patterns, suitable for high-volume production due to its speed and cost efficiency. You benefit from choosing digital printing for detailed, short runs, while rotary screen printing is optimal for large-scale, repetitive patterns and bulk orders.

Print Quality and Design Capabilities

Digital textile printing delivers superior print quality with high-resolution details and vibrant colors, enabling complex, multi-color designs and gradients that rotary screen printing cannot easily achieve. Rotary screen printing excels in producing consistent, sharp patterns on large production runs but is limited in color range and intricate design variations due to its reliance on fixed screens. The flexibility of digital printing supports rapid design changes and customization, making it ideal for short runs and intricate patterns with fine details.

Production Speed and Efficiency Comparison

Digital textile printing offers faster production speeds for small to medium runs by eliminating setup and screen preparation time, making it highly efficient for on-demand and customized designs. Rotary screen printing excels in high-volume production with consistent output, achieving faster throughput due to continuous screen rotation, but requires longer setup times and higher initial costs. Your choice depends on the balance between production volume and turnaround time, where digital printing suits rapid prototyping and rotary printing optimizes large-scale efficiency.

Cost Analysis: Initial Investment and Running Costs

Digital textile printing requires a lower initial investment due to minimal equipment costs compared to rotary screen printing, which demands expensive screens and machinery setups. Running costs for digital printing are generally higher per unit because of ink expenses, whereas rotary screen printing benefits from cost efficiency in large volume production with lower ink costs and faster output. Small to medium runs favor digital printing for flexibility and low setup expenses, while rotary screen printing offers economic advantages for large-scale textile manufacturing.

Suitability for Short and Long Runs

Digital textile printing excels in short runs due to its quick setup, cost-efficiency, and ability to produce intricate, multicolor designs without additional expenses for screens. Rotary screen printing is more suitable for long runs, offering consistent quality and lower per-unit costs when producing large quantities, despite the higher initial setup time and cost for screen preparation. Your choice depends on whether you prioritize flexibility and speed for small batches or cost-effectiveness and efficiency for mass production.

Environmental Impact and Sustainability

Digital textile printing significantly reduces water consumption and chemical waste compared to rotary screen printing, making it more environmentally sustainable. Rotary screen printing typically uses large volumes of water and generates higher amounts of effluent due to batch dyeing and extensive cleaning processes. The lower energy usage and minimal fabric waste of digital printing contribute to its growing preference in sustainable textile manufacturing.

Material and Ink Compatibility

Digital textile printing excels in material and ink compatibility, allowing for precise application on diverse fabrics such as cotton, polyester, silk, and blends using specialized water-based or pigment inks. Rotary screen printing, while traditionally optimized for cotton and other natural fibers, often uses plastisol or solvent-based inks that provide durability but have limited compatibility with synthetic or delicate materials. Both methods require careful selection of inks and pre-treatment processes to achieve optimal colorfastness and vibrancy on the targeted textile substrate.

Market Trends and Industry Adoption

Digital textile printing is rapidly gaining market share due to its flexibility, faster turnaround times, and ability to produce complex, customized designs with minimal waste. Rotary screen printing, while established and cost-effective for large volume runs, faces challenges as industries increasingly demand shorter production cycles and sustainable practices. Your choice between these technologies can significantly impact operational efficiency and market responsiveness amid the growing shift toward digital solutions.

Choosing the Right Printing Method for Your Business

Digital textile printing offers high-resolution designs with rapid turnaround times, ideal for small to medium production runs and customization, making it perfect for businesses targeting niche markets or fast fashion. Rotary screen printing excels in cost-efficiency and consistency for large-scale production volumes, providing vibrant colors and durability suitable for mass manufacturing. Selecting the right printing method depends on factors like production volume, design complexity, budget constraints, and desired fabric types, ensuring optimal operational efficiency and product quality.

Digital textile printing vs rotary screen printing Infographic

libmatt.com

libmatt.com