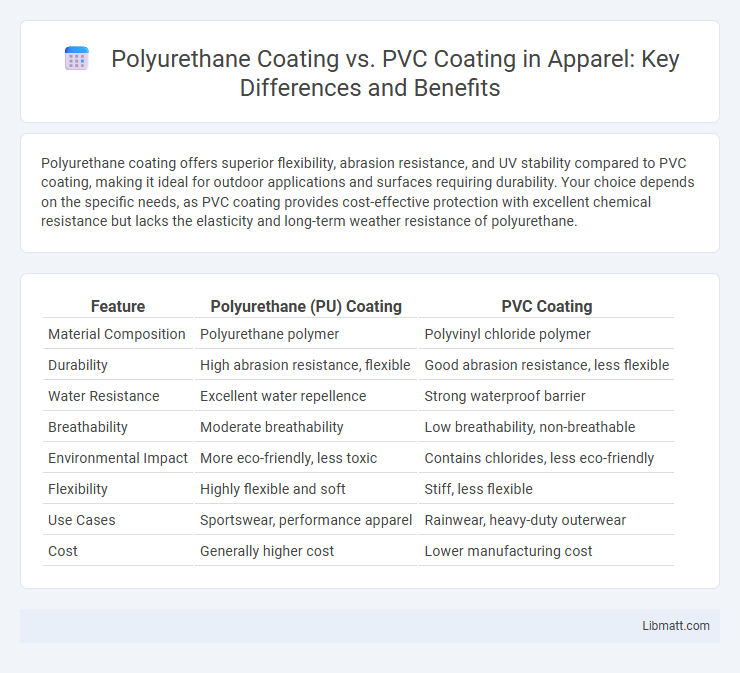

Polyurethane coating offers superior flexibility, abrasion resistance, and UV stability compared to PVC coating, making it ideal for outdoor applications and surfaces requiring durability. Your choice depends on the specific needs, as PVC coating provides cost-effective protection with excellent chemical resistance but lacks the elasticity and long-term weather resistance of polyurethane.

Table of Comparison

| Feature | Polyurethane (PU) Coating | PVC Coating |

|---|---|---|

| Material Composition | Polyurethane polymer | Polyvinyl chloride polymer |

| Durability | High abrasion resistance, flexible | Good abrasion resistance, less flexible |

| Water Resistance | Excellent water repellence | Strong waterproof barrier |

| Breathability | Moderate breathability | Low breathability, non-breathable |

| Environmental Impact | More eco-friendly, less toxic | Contains chlorides, less eco-friendly |

| Flexibility | Highly flexible and soft | Stiff, less flexible |

| Use Cases | Sportswear, performance apparel | Rainwear, heavy-duty outerwear |

| Cost | Generally higher cost | Lower manufacturing cost |

Introduction to Polyurethane and PVC Coatings

Polyurethane coatings offer exceptional durability, chemical resistance, and flexibility, making them ideal for harsh environments and high-wear applications. PVC coatings provide strong waterproofing, UV resistance, and cost-effectiveness, often used in outdoor fabrics and protective gear. Your choice between polyurethane and PVC coatings depends on the specific requirements for durability, flexibility, and exposure conditions.

Composition and Manufacturing Processes

Polyurethane coating consists of polymer chains formed by the reaction of polyols and isocyanates, providing flexibility and durability through a chemical curing process. PVC coating is made from polyvinyl chloride resin mixed with plasticizers and stabilizers, applied via a heat and pressure process to create a tough, weather-resistant finish. Understanding these composition differences helps you select coatings based on the desired elasticity, chemical resistance, and environmental exposure for your specific application.

Key Physical Properties Comparison

Polyurethane coating offers superior flexibility, abrasion resistance, and UV stability compared to PVC coating, making it ideal for applications requiring durability in harsh environments. PVC coating typically excels in chemical resistance and cost-effectiveness, but it is less flexible and prone to cracking under prolonged stress. Understanding these key physical properties helps you select the right material for optimal performance and longevity.

Durability and Longevity

Polyurethane coating offers superior durability and longevity due to its resistance to abrasion, chemicals, and UV exposure, making it ideal for long-term applications. PVC coating, while durable and highly flexible, tends to degrade faster under harsh environmental conditions such as extreme heat or prolonged sunlight. Your choice depends on the specific demands of your project, with polyurethane providing enhanced protection for extended service life.

Flexibility and Application Versatility

Polyurethane coating offers superior flexibility, making it ideal for applications requiring frequent bending and stretching without cracking. PVC coating provides excellent durability and chemical resistance but is generally less flexible, limiting its use in dynamic environments. Polyurethane's adaptability supports a wider range of applications including automotive, textiles, and electronics, while PVC is preferred for static uses such as roofing and piping.

Chemical and Environmental Resistance

Polyurethane coatings exhibit superior chemical resistance, particularly against solvents, oils, and abrasion, making them ideal for harsh industrial applications. PVC coatings offer excellent resistance to acids, alkalis, and weathering, providing durable protection in outdoor and marine environments. Both coatings have differing environmental impacts, with polyurethane generally being more environmentally friendly due to lower plasticizer content and better recyclability.

Cost Efficiency and Value Analysis

Polyurethane coatings offer superior durability and UV resistance, making them more cost-efficient over time despite a higher initial investment compared to PVC coatings. PVC coatings, while generally cheaper upfront, tend to wear out faster and may incur higher maintenance and replacement costs. Evaluating the total lifecycle cost reveals that polyurethane coatings provide better value for applications requiring long-term performance and exposure to harsh conditions.

Safety and Environmental Impact

Polyurethane coatings offer superior chemical resistance and durability with low VOC emissions, making them safer for indoor environments compared to PVC coatings, which can release harmful dioxins and phthalates during production and disposal. The biodegradability of polyurethane coatings is generally better, reducing long-term environmental impact, whereas PVC coatings contribute to persistent plastic pollution and are less eco-friendly. Choosing polyurethane coatings supports safer handling and sustainability goals in industrial and consumer applications.

Common Applications and Use Cases

Polyurethane coating is commonly used for automotive finishes, industrial equipment, and flooring due to its excellent abrasion resistance and flexibility. PVC coating finds frequent application in outdoor fabrics, rainwear, and inflatable products because of its superb waterproof and weather-resistant properties. Understanding these use cases can help you select the ideal coating based on durability and environmental exposure.

Choosing the Right Coating: Factors to Consider

Selecting between polyurethane (PU) and PVC coatings depends on factors such as durability, flexibility, and environmental resistance. PU coatings offer superior abrasion resistance and elasticity, making them ideal for applications requiring flexibility and longevity, while PVC coatings excel in chemical resistance and cost-effectiveness. Consider the specific use case, exposure conditions, and budget to determine the optimal coating for protection and performance.

Polyurethane coating vs PVC coating Infographic

libmatt.com

libmatt.com