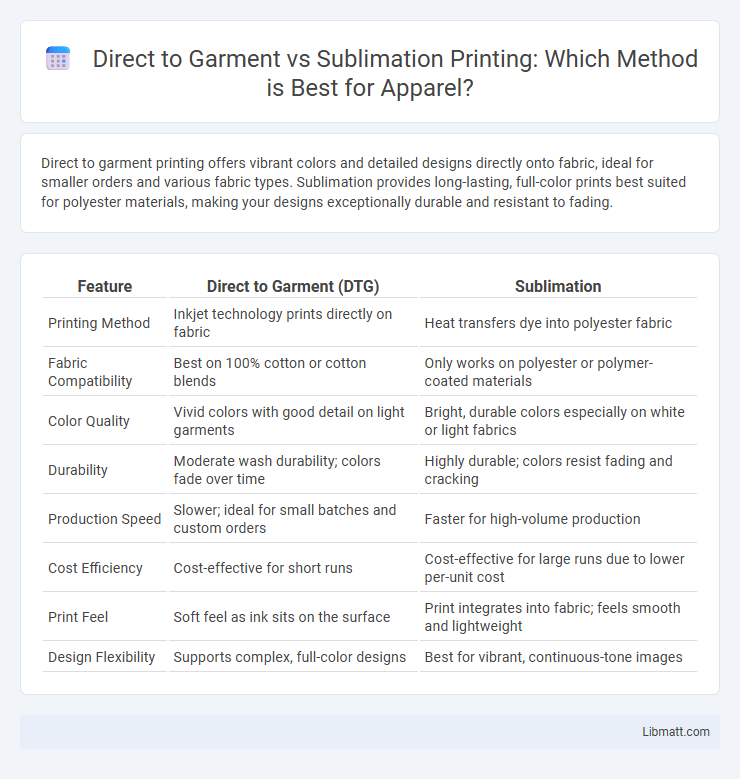

Direct to garment printing offers vibrant colors and detailed designs directly onto fabric, ideal for smaller orders and various fabric types. Sublimation provides long-lasting, full-color prints best suited for polyester materials, making your designs exceptionally durable and resistant to fading.

Table of Comparison

| Feature | Direct to Garment (DTG) | Sublimation |

|---|---|---|

| Printing Method | Inkjet technology prints directly on fabric | Heat transfers dye into polyester fabric |

| Fabric Compatibility | Best on 100% cotton or cotton blends | Only works on polyester or polymer-coated materials |

| Color Quality | Vivid colors with good detail on light garments | Bright, durable colors especially on white or light fabrics |

| Durability | Moderate wash durability; colors fade over time | Highly durable; colors resist fading and cracking |

| Production Speed | Slower; ideal for small batches and custom orders | Faster for high-volume production |

| Cost Efficiency | Cost-effective for short runs | Cost-effective for large runs due to lower per-unit cost |

| Print Feel | Soft feel as ink sits on the surface | Print integrates into fabric; feels smooth and lightweight |

| Design Flexibility | Supports complex, full-color designs | Best for vibrant, continuous-tone images |

Introduction to Direct to Garment (DTG) and Sublimation

Direct to Garment (DTG) printing uses specialized inkjet technology to apply water-based inks directly onto cotton or cotton-blend fabrics, producing vibrant and detailed images ideal for small batch or custom orders. Sublimation printing involves transferring dye onto polyester or polymer-coated materials through heat and pressure, resulting in durable, full-color designs that are embedded into the fabric fibers. DTG is best suited for natural fibers and complex color gradients, while sublimation excels in polyester materials with a long-lasting, vibrant finish.

How Direct to Garment Printing Works

Direct to garment printing works by using specialized inkjet technology to apply water-based inks directly onto fabric fibers, allowing for high-resolution, full-color designs with intricate detail. The printer deposits the ink precisely where required, which then soaks into the fabric and is cured using heat to ensure durability and vibrancy. Your designs benefit from the ability to print without screens or plates, making it ideal for small runs and custom apparel.

The Sublimation Printing Process Explained

The sublimation printing process involves transferring dye onto polyester fabric using heat and pressure, allowing the ink to become part of the fabric itself. This results in vibrant, long-lasting colors that resist fading, cracking, and peeling, especially on synthetic materials designed for sublimation. Understanding how sublimation differs from direct to garment printing can help you choose the best method for your custom apparel needs.

Material Compatibility: DTG vs Sublimation

Direct to Garment (DTG) excels in printing on a wide range of natural fibers, particularly 100% cotton, offering vibrant colors and detailed designs. Sublimation works best on polyester or polymer-coated fabrics, ensuring durable, full-color images that become part of the material itself. Your choice between DTG and sublimation should depend on the fabric type and desired print longevity.

Print Quality and Color Vibrancy Comparison

Direct to garment (DTG) printing delivers exceptional print quality with sharp details and smooth gradients, making it ideal for complex designs on cotton fabrics. Sublimation printing, on the other hand, excels in color vibrancy and durability, producing bright, long-lasting prints best suited for polyester materials. Your choice should consider fabric type and desired color intensity to achieve the best results.

Durability and Washability of Prints

Direct to garment (DTG) prints offer high durability with vibrant colors that penetrate fabric fibers, ensuring washability without significant fading after numerous laundry cycles. Sublimation prints excel on polyester fabrics, providing exceptional colorfastness and resistance to cracking or peeling, maintaining sharpness even after repeated washing. Your choice between DTG and sublimation should consider fabric type and desired print longevity to achieve the best durability and washability results.

Production Speed and Order Volume Considerations

Direct-to-garment (DTG) printing offers faster setup and is ideal for small to medium order volumes, enabling quick turnaround times for custom designs on demand. Sublimation printing excels in high-volume production, providing consistent color vibrancy and durability but requires longer preparation and curing times. Your choice depends on whether rapid production or batch processing efficiency aligns better with your business needs.

Cost Analysis: DTG vs Sublimation

Direct to Garment (DTG) printing generally incurs higher upfront equipment costs, averaging $10,000 to $30,000, compared to sublimation printers, which range from $500 to $5,000. Ink expenses for DTG are significantly higher, with cost per print often reaching $0.50 to $1.00, while sublimation ink costs lower, typically $0.10 to $0.30 per print. Maintenance for DTG printers demands frequent and costly upkeep, whereas sublimation printers experience fewer maintenance issues, leading to lower long-term operational expenses.

Environmental Impact and Sustainability

Direct to garment (DTG) printing generally has a lower environmental impact than sublimation due to its water-based inks and minimal waste production, making it a more sustainable choice for eco-conscious consumers. Sublimation requires polyester fabrics and uses chemical dyes that can contribute to pollution and are less biodegradable. Your decision between DTG and sublimation should consider the ecological footprint of ink and fabric materials alongside durability and print quality.

Choosing the Right Printing Method for Your Needs

Direct to Garment (DTG) printing excels in producing vibrant, detailed designs on cotton fabrics, making it ideal for custom apparel with complex graphics. Sublimation works best on polyester or polymer-coated surfaces, offering durable, fade-resistant prints suitable for athletic wear and promotional items. Choosing the right printing method for your needs depends on fabric type, design complexity, and intended use to ensure the best quality and longevity.

direct to garment vs sublimation Infographic

libmatt.com

libmatt.com