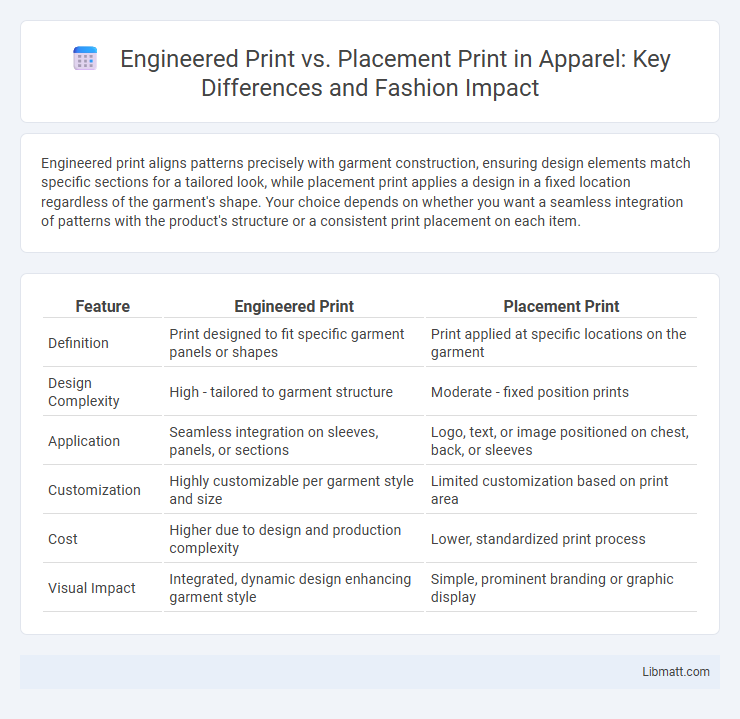

Engineered print aligns patterns precisely with garment construction, ensuring design elements match specific sections for a tailored look, while placement print applies a design in a fixed location regardless of the garment's shape. Your choice depends on whether you want a seamless integration of patterns with the product's structure or a consistent print placement on each item.

Table of Comparison

| Feature | Engineered Print | Placement Print |

|---|---|---|

| Definition | Print designed to fit specific garment panels or shapes | Print applied at specific locations on the garment |

| Design Complexity | High - tailored to garment structure | Moderate - fixed position prints |

| Application | Seamless integration on sleeves, panels, or sections | Logo, text, or image positioned on chest, back, or sleeves |

| Customization | Highly customizable per garment style and size | Limited customization based on print area |

| Cost | Higher due to design and production complexity | Lower, standardized print process |

| Visual Impact | Integrated, dynamic design enhancing garment style | Simple, prominent branding or graphic display |

Introduction to Engineered Print and Placement Print

Engineered print involves designs tailored to fit specific fabric shapes and garment patterns, ensuring precise alignment of motifs on each piece. Placement print refers to pre-determined graphics positioned strategically on fabric, allowing you to control exactly where the design appears on the final product. Both techniques optimize visual impact while enhancing garment aesthetics through careful pattern planning.

Defining Engineered Print: Key Characteristics

Engineered print features a design tailored to fit specific garment panels, ensuring precise alignment and enhanced visual impact. Unlike placement print, which simply positions a standard graphic on fabric, engineered print integrates patterns that follow the garment's contours and seams. Your designs benefit from this technique by achieving a more customized, high-quality appearance that emphasizes detail and craftsmanship.

Placement Print Explained: Fundamentals and Uses

Placement print involves printing a specific design precisely positioned on a garment, ensuring consistent alignment across multiple items. This technique is essential for branding and promotional apparel, where exact placement enhances visual impact and professional appearance. Your custom garments benefit from this method by maintaining uniformity and meeting design specifications accurately.

Design Flexibility: Engineered Print vs Placement Print

Engineered prints offer superior design flexibility by allowing seamless patterns tailored to garment shapes, ensuring precise alignment and minimizing fabric waste. Placement prints require exact positioning on a flat fabric before garment construction, limiting adaptability during production and design modifications. Your choice impacts customization potential, especially for complex designs needing perfect pattern flow and minimal distortion.

Production Process Differences

Engineered print involves printing large, continuous designs precisely aligned with the garment's shape, requiring digital or rotary screen printing for accurate placement during production. Placement print focuses on applying specific graphics or patterns at designated locations on the fabric, often utilizing flatbed screen printing or heat transfer methods. Your choice impacts production speed, cost, and the complexity of design application, with engineered prints demanding more advanced technology for seamless integration.

Visual Impact and Aesthetic Appeal

Engineered prints deliver precise, intricate designs tailored to fit garment construction lines, creating a seamless and polished visual effect that enhances the overall aesthetic appeal. Placement prints are strategically positioned on specific areas of the garment, emphasizing focal points for bold, statement-making visuals. Both techniques optimize design impact, with engineered prints offering cohesion and placement prints providing targeted emphasis for maximum visual engagement.

Cost Implications and Scalability

Engineered print offers cost advantages through optimized fabric utilization and reduced material waste, making it ideal for limited runs with complex designs. Placement print requires precise alignment and is less material-efficient, increasing labor costs and limiting scalability for large production. Scalability favors engineered print due to streamlined manufacturing processes and lower per-unit costs at higher volumes.

Application in Fashion and Home Textiles

Engineered prints are tailored designs applied precisely to specific garment sections, enhancing fit and visual impact in fashion by tailoring patterns to panel shapes or body contours. Placement prints are strategically positioned motifs or graphics on fabric surfaces, commonly used in both fashion and home textiles to create focal points or decorative elements on items like cushions, curtains, and apparel. While engineered prints optimize design alignment and garment construction in fashion, placement prints offer versatility for adding distinctive aesthetic touches across various textile products.

Sustainability Considerations

Engineered print designs minimize fabric waste by precisely aligning patterns with garment pieces, enhancing sustainability through efficient material usage. Placement prints, while offering creative flexibility, often result in higher fabric offcuts and increased resource consumption. Choosing engineered prints supports Your brand's commitment to eco-friendly production and reduces the environmental footprint throughout the manufacturing process.

Choosing the Right Print Method for Your Project

Engineered prints offer precise, strategic pattern alignment that enhances garment fit and design, ideal for complex, tailored projects. Placement prints allow for specific motif positioning on fabric, perfect for bold, statement pieces where exact image location matters. Your project's design complexity and desired visual outcome determine the optimal choice between engineered and placement printing methods for exceptional results.

engineered print vs placement print Infographic

libmatt.com

libmatt.com