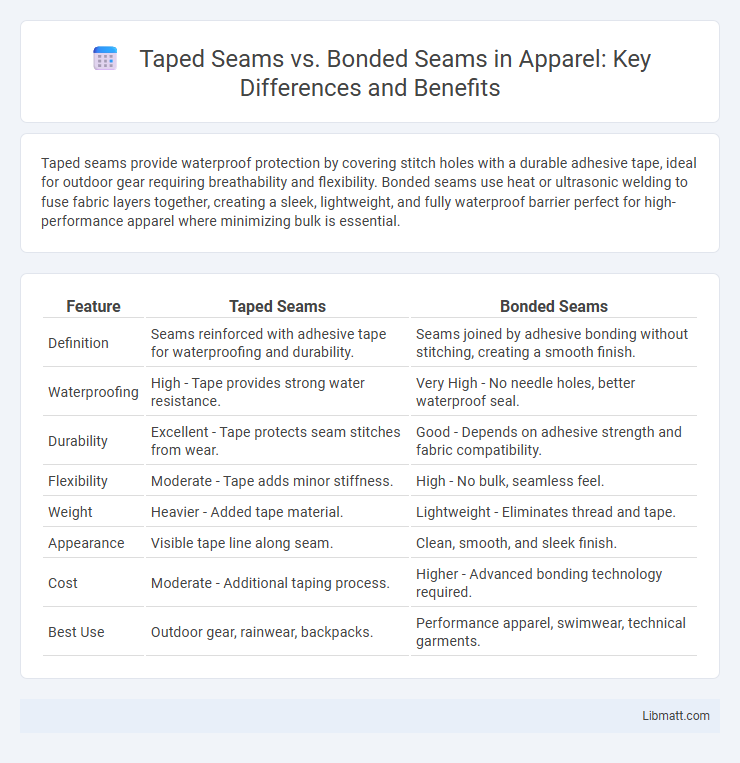

Taped seams provide waterproof protection by covering stitch holes with a durable adhesive tape, ideal for outdoor gear requiring breathability and flexibility. Bonded seams use heat or ultrasonic welding to fuse fabric layers together, creating a sleek, lightweight, and fully waterproof barrier perfect for high-performance apparel where minimizing bulk is essential.

Table of Comparison

| Feature | Taped Seams | Bonded Seams |

|---|---|---|

| Definition | Seams reinforced with adhesive tape for waterproofing and durability. | Seams joined by adhesive bonding without stitching, creating a smooth finish. |

| Waterproofing | High - Tape provides strong water resistance. | Very High - No needle holes, better waterproof seal. |

| Durability | Excellent - Tape protects seam stitches from wear. | Good - Depends on adhesive strength and fabric compatibility. |

| Flexibility | Moderate - Tape adds minor stiffness. | High - No bulk, seamless feel. |

| Weight | Heavier - Added tape material. | Lightweight - Eliminates thread and tape. |

| Appearance | Visible tape line along seam. | Clean, smooth, and sleek finish. |

| Cost | Moderate - Additional taping process. | Higher - Advanced bonding technology required. |

| Best Use | Outdoor gear, rainwear, backpacks. | Performance apparel, swimwear, technical garments. |

Introduction to Seam Sealing Methods

Taped seams involve applying a waterproof tape over stitched areas to prevent water penetration, commonly used in outdoor gear for high durability and reliability. Bonded seams use adhesives to fuse fabric layers together without stitching, offering a sleek, lightweight, and flexible finish ideal for athletic wear and performance fabrics. Choosing between taped seams and bonded seams depends on your need for waterproofing strength versus design flexibility and comfort.

What Are Taped Seams?

Taped seams are waterproof closures where a special adhesive tape is applied over stitched seams to prevent water from penetrating through needle holes. This technique enhances the durability and moisture resistance of outdoor gear, making it ideal for rain jackets and tents. If you need reliable weather protection, your gear with taped seams ensures superior waterproof performance compared to standard stitch-only seams.

What Are Bonded Seams?

Bonded seams are created by fusing fabric edges together using adhesives or heat, forming a strong, watertight bond without stitching. This technique enhances garment durability and reduces bulk, making it ideal for performance wear like waterproof jackets and activewear. Bonded seams provide superior resistance to moisture penetration compared to traditional taped seams, ensuring optimal protection in harsh weather conditions.

Key Differences: Taped Seams vs Bonded Seams

Taped seams use adhesive tape applied over stitched seam lines to enhance waterproofing and durability, commonly found in high-performance outdoor gear. Bonded seams eliminate stitching by fusing fabric layers together using heat, pressure, or ultrasonic techniques, resulting in a cleaner look and increased comfort with reduced bulk. The choice between taped and bonded seams depends on factors like waterproof requirements, garment flexibility, manufacturing cost, and intended use environment.

Durability Comparison

Taped seams provide superior durability by reinforcing stitch holes with waterproof tape, preventing water penetration and enhancing seam strength, especially in high-stress areas of outdoor gear. Bonded seams rely on adhesives or heat fusion to join fabric layers, which can offer a smooth, flexible finish but may be less resistant to abrasion and repeated stress over time. For long-lasting performance in demanding environments, taped seams are generally more robust and reliable than bonded seams.

Waterproofing Performance

Taped seams provide superior waterproofing performance by covering stitch holes with a waterproof tape, effectively preventing water penetration in high-pressure or prolonged wet conditions. Bonded seams use adhesives to fuse fabric layers together, creating a smooth, lightweight barrier that enhances water resistance but may be less durable under extreme stress. For outdoor gear, taped seams are preferred in heavy rain scenarios, while bonded seams offer a more flexible and breathable option with moderate waterproof protection.

Applications in Outdoor Gear and Apparel

Taped seams provide waterproof protection by sealing stitch holes, making them ideal for heavy-duty outdoor gear like rain jackets and tents exposed to prolonged moisture. Bonded seams use adhesive technology to fuse fabric edges, offering a sleek, lightweight solution favored in high-performance activewear and lightweight backpacks where minimal bulk and flexibility are essential. Both seam types enhance durability and weather resistance but serve distinct functions based on the outdoor activity's demands and fabric characteristics.

Comfort and Flexibility

Taped seams provide a waterproof barrier while maintaining a flexible and comfortable fit, making them ideal for activewear and outdoor gear. Bonded seams offer a sleek, smooth finish that reduces bulk and irritation, enhancing overall comfort during prolonged wear. Choosing your preferred seam type depends on balancing waterproof performance with the level of flexibility required for your activities.

Cost and Manufacturing Considerations

Taped seams generally incur higher manufacturing costs due to the additional labor and materials required to apply waterproof tape, which enhances seam durability and water resistance. Bonded seams utilize adhesives and heat or pressure to fuse fabric panels, offering a cost-effective and faster production process with reduced material overlap and weight. Choosing between taped and bonded seams hinges on balancing budget constraints with desired product performance, as taped seams often deliver superior waterproofing at an increased cost compared to the economical and lightweight benefits of bonded seams.

Choosing the Right Seam Technology

Choosing the right seam technology depends on your priorities for durability, waterproofing, and comfort. Taped seams use a strong adhesive tape over stitched areas, providing reliable waterproofing and flexibility, ideal for active wear and outdoor gear. Bonded seams fuse fabric edges together without stitching, offering a sleek, lightweight design with enhanced water resistance but may sacrifice some durability under heavy stress.

Taped seams vs bonded seams Infographic

libmatt.com

libmatt.com