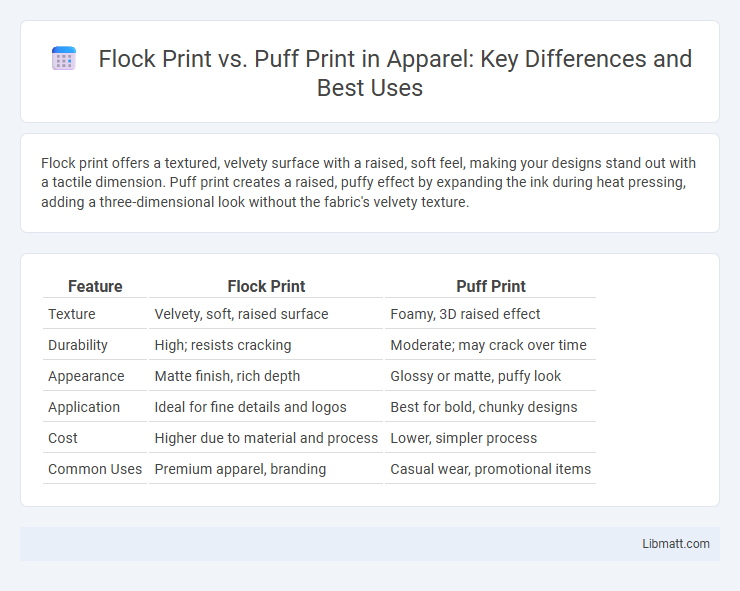

Flock print offers a textured, velvety surface with a raised, soft feel, making your designs stand out with a tactile dimension. Puff print creates a raised, puffy effect by expanding the ink during heat pressing, adding a three-dimensional look without the fabric's velvety texture.

Table of Comparison

| Feature | Flock Print | Puff Print |

|---|---|---|

| Texture | Velvety, soft, raised surface | Foamy, 3D raised effect |

| Durability | High; resists cracking | Moderate; may crack over time |

| Appearance | Matte finish, rich depth | Glossy or matte, puffy look |

| Application | Ideal for fine details and logos | Best for bold, chunky designs |

| Cost | Higher due to material and process | Lower, simpler process |

| Common Uses | Premium apparel, branding | Casual wear, promotional items |

Introduction to Flock Print and Puff Print

Flock print uses tiny fiber particles deposited onto adhesive to create a raised, velvety texture on fabrics, enhancing tactile appeal and durability. Puff print involves a heat-activated ink that expands during curing, producing a soft, puffy, three-dimensional design ideal for bold graphics on textiles. Both techniques offer unique textured effects, with flock print providing a fuzzy finish and puff print delivering a lightweight, raised appearance.

What is Flock Print?

Flock print is a textile printing technique that uses tiny fiber particles applied to adhesive-coated fabrics, creating a raised, velvety texture that adds depth and tactile interest to garments. This method is highly durable and offers vibrant color retention, making it a popular choice for logos, lettering, and decorative accents on apparel. You can choose flock print to achieve a soft, fuzzy surface that enhances both visual appeal and fabric dimension.

What is Puff Print?

Puff print is a screen printing technique that creates a raised, three-dimensional texture on fabric by using a specialized ink that expands when heated, providing a tactile and visually striking effect. This method contrasts with flock print, which uses adhesive and fibers to achieve a velvety, plush surface; puff print offers more volume but less softness than flock. Your choice between puff print and flock print depends on the desired texture and appearance for apparel or promotional items.

Key Differences Between Flock Print and Puff Print

Flock print uses fine fibers to create a velvety, textured surface, while puff print applies a heat-activated ink that expands, giving a raised, three-dimensional effect. Flock print offers a soft, fabric-like feel and is more durable against cracking, whereas puff print provides a bold, puffy appearance but can be less flexible over time. Your choice depends on whether you prefer a tactile softness with flock or a visually striking 3D look with puff print.

Materials and Equipment Required

Flock printing requires specialized materials such as nylon or rayon fibers and adhesives, along with equipment like applicator machines and curing ovens to press fibers onto fabric, creating a velvet-like texture. Puff printing uses thermoplastic inks mixed with a blowing agent, applied via screen printing and cured with heat presses to raise the printed area, producing a three-dimensional effect. Both methods demand precise temperature and time control to ensure proper adhesion and texture durability on textiles.

Design Possibilities for Flock and Puff Prints

Flock prints offer a velvety texture that enhances intricate designs with a soft, raised surface, making them ideal for detailed logos and patterns that require a tactile feel. Puff prints create a three-dimensional, puffy effect by expanding during heat application, adding boldness and volume to simple shapes and lettering. Your choice between flock and puff print depends on whether you want a smooth, fabric-like finish or a pronounced, textured appearance that makes designs visually and physically stand out.

Durability and Washability Comparison

Flock print offers superior durability and resists cracking or peeling over multiple washes due to its textured, velvety finish created by tiny fibers adhering to the fabric. Puff print, while providing a raised, three-dimensional effect, tends to be less durable and may crack or lose its volume after repeated laundering. Your choice between flock and puff print should consider the garment's intended use and desired longevity, with flock being more suitable for long-lasting, wash-resistant designs.

Cost Factors: Flock Print vs Puff Print

Flock print typically incurs higher costs due to specialized fibers and a longer drying process, making it more expensive than puff print. Puff print, using heat-activated inks that expand upon curing, tends to be more cost-effective for bulk orders. Your choice between these methods should consider budget constraints alongside the desired texture and durability.

Best Applications for Each Printing Method

Flock print excels in creating textured, velvety designs ideal for apparel like sportswear and promotional items requiring a soft, raised surface and durability. Puff print is best suited for vibrant, raised effects on casual clothing and cotton fabrics, offering a bold 3D appearance that enhances graphic visibility. Both methods optimize fabric compatibility and design complexity, with flock print favored for tactile finishes and puff print for colorful, eye-catching details.

Choosing the Right Print for Your Project

Flock print offers a soft, velvety texture ideal for designs needing a plush, raised feel, while puff print provides a three-dimensional, slightly puffy effect perfect for bold, eye-catching visuals. Consider flock print when aiming for a sophisticated, tactile finish that stands out subtly, whereas puff print suits vibrant, dynamic projects demanding noticeable texture. Your choice depends on the desired aesthetic and tactile experience, ensuring the print complements your project's style and purpose seamlessly.

flock print vs puff print Infographic

libmatt.com

libmatt.com