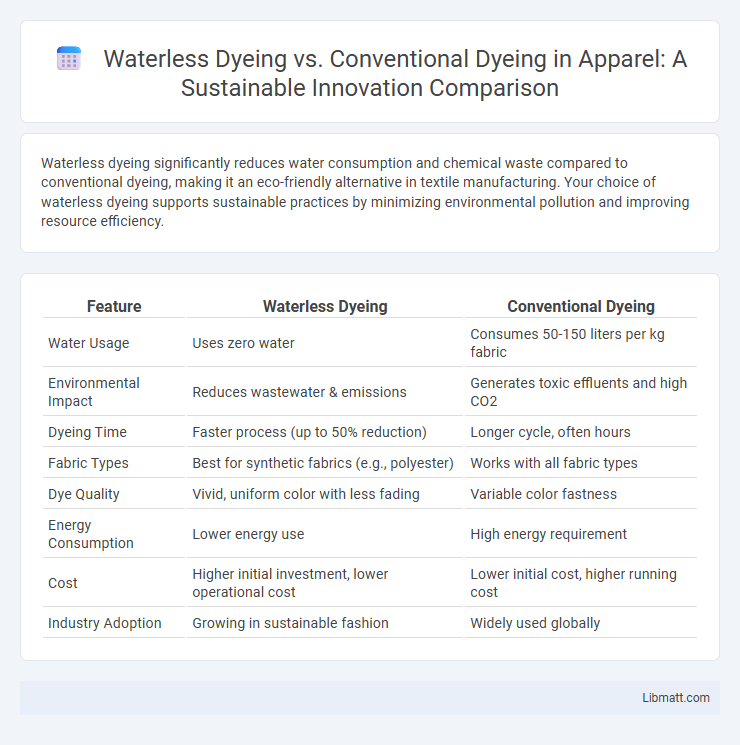

Waterless dyeing significantly reduces water consumption and chemical waste compared to conventional dyeing, making it an eco-friendly alternative in textile manufacturing. Your choice of waterless dyeing supports sustainable practices by minimizing environmental pollution and improving resource efficiency.

Table of Comparison

| Feature | Waterless Dyeing | Conventional Dyeing |

|---|---|---|

| Water Usage | Uses zero water | Consumes 50-150 liters per kg fabric |

| Environmental Impact | Reduces wastewater & emissions | Generates toxic effluents and high CO2 |

| Dyeing Time | Faster process (up to 50% reduction) | Longer cycle, often hours |

| Fabric Types | Best for synthetic fabrics (e.g., polyester) | Works with all fabric types |

| Dye Quality | Vivid, uniform color with less fading | Variable color fastness |

| Energy Consumption | Lower energy use | High energy requirement |

| Cost | Higher initial investment, lower operational cost | Lower initial cost, higher running cost |

| Industry Adoption | Growing in sustainable fashion | Widely used globally |

Overview of Waterless Dyeing and Conventional Dyeing

Waterless dyeing utilizes supercritical carbon dioxide to infuse dyes into textiles, significantly reducing water consumption and chemical waste compared to conventional dyeing, which relies heavily on large volumes of water for dye bath preparation and fabric rinsing. Conventional dyeing typically causes higher environmental impacts due to water pollution from effluents containing excess dyes and auxiliaries, whereas waterless dyeing technology offers a more sustainable alternative with lower energy use and minimal wastewater. Textile manufacturers increasingly adopt waterless dyeing to meet stringent environmental regulations and reduce operational costs associated with water treatment and resource management.

History and Evolution of Textile Dyeing Methods

Waterless dyeing, pioneered in the early 21st century, emerged as an eco-friendly alternative to conventional dyeing methods, which date back thousands of years and rely heavily on water-intensive processes. Traditional textile dyeing evolved from natural dyes extracted from plants and insects to synthetic dyes developed during the Industrial Revolution, significantly expanding colorfastness and production speed. Recent innovations in waterless dyeing utilize carbon dioxide or supercritical fluids, reducing water consumption by up to 90% and minimizing environmental pollution compared to centuries-old water-based dyeing techniques.

Key Differences in Dyeing Processes

Waterless dyeing eliminates the use of water by employing supercritical carbon dioxide to carry dye into fibers, resulting in reduced water consumption and lower environmental impact. Conventional dyeing relies heavily on water as a medium to disperse dyes and fix colors onto textiles, which generates substantial wastewater requiring treatment. The key differences lie in resource utilization, with waterless dyeing offering a more sustainable approach by minimizing water usage and chemical runoff compared to traditional water-intensive processes.

Environmental Impact Comparison

Waterless dyeing significantly reduces water consumption by up to 90% compared to conventional dyeing methods, minimizing water pollution and conserving vital freshwater resources. Conventional dyeing processes often release toxic chemicals and untreated wastewater, contributing to soil and water contamination, whereas waterless dyeing uses supercritical carbon dioxide or other environmentally friendly technologies that eliminate harmful effluents. Choosing waterless dyeing for Your textile production supports sustainable practices by lowering carbon footprint and reducing chemical waste.

Water Usage: Conservation vs Consumption

Waterless dyeing dramatically reduces water consumption by utilizing technologies like supercritical CO2, conserving millions of liters per production cycle compared to conventional dyeing processes that consume up to 150 liters of water per kilogram of fabric. This conservation significantly alleviates environmental pressure on freshwater resources and minimizes wastewater treatment challenges. Your choice of waterless dyeing supports sustainable textile manufacturing with a substantial decrease in water usage and ecological footprint.

Energy Efficiency and Resource Requirements

Waterless dyeing significantly reduces water consumption by using supercritical carbon dioxide, thereby cutting energy costs associated with heating large volumes of water in conventional dyeing processes. This method lowers energy usage by approximately 50-70%, as it eliminates the need for water evaporation and wastewater treatment. Conventional dyeing requires vast quantities of water and chemical additives, resulting in higher energy demands for water heating, pumping, and effluent management.

Color Quality and Fastness

Waterless dyeing technology offers superior color vibrancy and uniformity compared to conventional dyeing methods, resulting in richer and more consistent hues. This process enhances color fastness, providing improved resistance to fading, washing, and rubbing, thereby extending the garment's lifespan. Conventional dyeing often experiences uneven dye uptake and lower fastness levels due to water's role in dye dispersion and fixation limitations.

Industrial Adoption and Implementation

Waterless dyeing offers significant advantages over conventional dyeing by reducing water usage by up to 90% and lowering chemical waste, making it increasingly attractive for industrial adoption. Major textile manufacturers have started implementing supercritical CO2 dyeing technology to meet sustainability targets and comply with stringent environmental regulations. Your investment in waterless dyeing can enhance production efficiency while positioning your operations as eco-friendly leaders in the textile industry.

Economic Considerations and Cost Analysis

Waterless dyeing significantly reduces water and energy consumption, leading to lower utility costs and less wastewater treatment expense compared to conventional dyeing methods. Although initial investment in waterless dyeing technology can be higher, operational savings and increased production efficiency often result in a lower total cost of ownership over time. Conventional dyeing incurs expenses related to large water usage, chemical treatments, and environmental compliance, which elevate long-term operational costs.

Future Prospects and Innovations in Textile Dyeing

Waterless dyeing technologies, such as supercritical CO2 dyeing, present significant future prospects by reducing water consumption by up to 90% and eliminating wastewater treatment costs. Innovations integrating nanotechnology and digital color matching enhance precision and reduce environmental impact compared to conventional dyeing methods reliant on vast volumes of water and chemical effluents. The textile industry's shift towards sustainable dyeing solutions is driven by regulatory pressures and consumer demand for eco-friendly products, positioning waterless dyeing at the forefront of next-generation textile manufacturing.

Waterless dyeing vs conventional dyeing Infographic

libmatt.com

libmatt.com