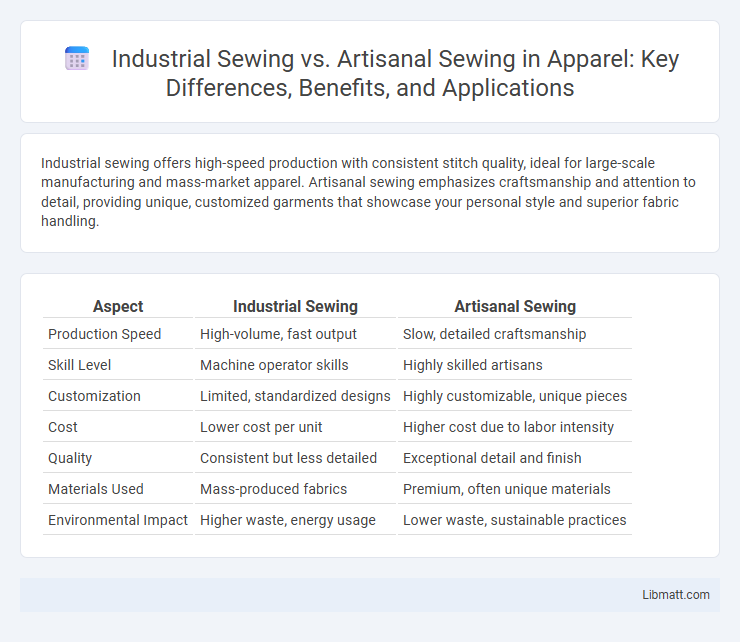

Industrial sewing offers high-speed production with consistent stitch quality, ideal for large-scale manufacturing and mass-market apparel. Artisanal sewing emphasizes craftsmanship and attention to detail, providing unique, customized garments that showcase your personal style and superior fabric handling.

Table of Comparison

| Aspect | Industrial Sewing | Artisanal Sewing |

|---|---|---|

| Production Speed | High-volume, fast output | Slow, detailed craftsmanship |

| Skill Level | Machine operator skills | Highly skilled artisans |

| Customization | Limited, standardized designs | Highly customizable, unique pieces |

| Cost | Lower cost per unit | Higher cost due to labor intensity |

| Quality | Consistent but less detailed | Exceptional detail and finish |

| Materials Used | Mass-produced fabrics | Premium, often unique materials |

| Environmental Impact | Higher waste, energy usage | Lower waste, sustainable practices |

Introduction to Industrial and Artisanal Sewing

Industrial sewing utilizes automated machines designed for high-volume production, delivering consistent and rapid output ideal for mass manufacturing. In contrast, artisanal sewing emphasizes skilled craftsmanship and attention to detail, producing unique, high-quality garments with personalized touches. Understanding the differences in techniques and outcomes can help you choose the best method for your sewing projects based on efficiency or customization needs.

Historical Overview of Sewing Techniques

Industrial sewing emerged during the Industrial Revolution in the 18th century, revolutionizing garment production with mechanized stitching techniques that significantly increased speed and efficiency. Artisanal sewing, rooted in centuries-old handcraft traditions, emphasizes meticulous hand-stitching and personalized detail that reflect cultural heritage and skilled craftsmanship. The contrast between industrial and artisanal sewing highlights the evolution from mass-produced textiles to unique, handcrafted garments valued for their artisanal quality and historical significance.

Machinery: Industrial Automation vs. Handcrafted Tools

Industrial sewing relies on advanced machinery with automation capabilities that significantly boost production speed, precision, and consistency, utilizing computerized sewing machines and automated thread cutters. Artisanal sewing depends on handcrafted tools such as manual sewing machines, specialized needles, and hand-guided stitching techniques that emphasize detailed craftsmanship and unique design elements. Your choice between these methods impacts product quality, production scale, and customization potential.

Production Speed and Output Efficiency

Industrial sewing machines deliver significantly higher production speed and output efficiency by automating repetitive tasks and handling multiple layers of fabric quickly. Artisanal sewing focuses on handcrafted precision, resulting in slower production rates but greater attention to detail and customization. Your choice between the two depends on whether speed or craftsmanship is the primary priority for your project.

Quality Control: Consistency vs. Uniqueness

Industrial sewing ensures consistency through automated quality control systems that maintain uniformity across large production batches, minimizing defects and variations. Artisanal sewing emphasizes uniqueness, with skilled craftsmen closely inspecting each piece to produce distinct, high-quality items that showcase individual creativity. Your choice depends on whether you prioritize standardized precision or personalized detail in sewn products.

Material Sourcing and Sustainability Practices

Industrial sewing relies heavily on mass-produced, synthetic materials sourced globally, often prioritizing cost-efficiency over sustainability, which can lead to significant environmental impact. Artisanal sewing typically involves carefully selected, locally sourced natural materials, reducing carbon footprints and supporting sustainable practices. Your choice between industrial and artisanal sewing affects material sustainability and the ethical footprint of the final product.

Cost Implications for Producers and Consumers

Industrial sewing significantly reduces production costs due to automation and high-speed machinery, enabling producers to manufacture large quantities at lower expenses. Artisanal sewing involves higher labor costs and longer production times, reflecting in premium pricing that appeals to consumers seeking unique, handcrafted quality. Your choice between industrial and artisanal sewing impacts affordability and value, balancing mass-market efficiency against bespoke craftsmanship.

Skill Requirements and Workforce Expertise

Industrial sewing demands proficiency in operating complex machinery and adherence to standardized production processes, requiring workers to have specialized technical training. Artisanal sewing relies heavily on highly skilled craftsmanship, with artisans mastering intricate hand-stitching techniques and creative design adaptations passed down through generations. You benefit from understanding that while industrial workforce expertise centers on efficiency and machine handling, artisanal sewing emphasizes individual skill and artistic precision.

Applications: Mass Production vs. Bespoke Creations

Industrial sewing excels in mass production, enabling rapid manufacturing of standardized garments and textiles for large-scale retail distribution. Artisanal sewing focuses on bespoke creations, emphasizing craftsmanship, unique designs, and personalized details tailored to individual customer preferences. Your choice between these methods depends on whether you prioritize high-volume output or customized, high-quality pieces.

The Future of Sewing: Trends and Innovations

Industrial sewing leverages automation, precision machinery, and advanced software to boost production efficiency and consistency, meeting large-scale manufacturing demands. Artisanal sewing emphasizes handcrafted techniques, customization, and sustainable practices, appealing to niche markets valuing uniqueness and quality. Your sewing future will increasingly blend these innovations, integrating smart technology with traditional craftsmanship to create versatile, eco-friendly, and high-quality textiles.

industrial sewing vs artisanal sewing Infographic

libmatt.com

libmatt.com