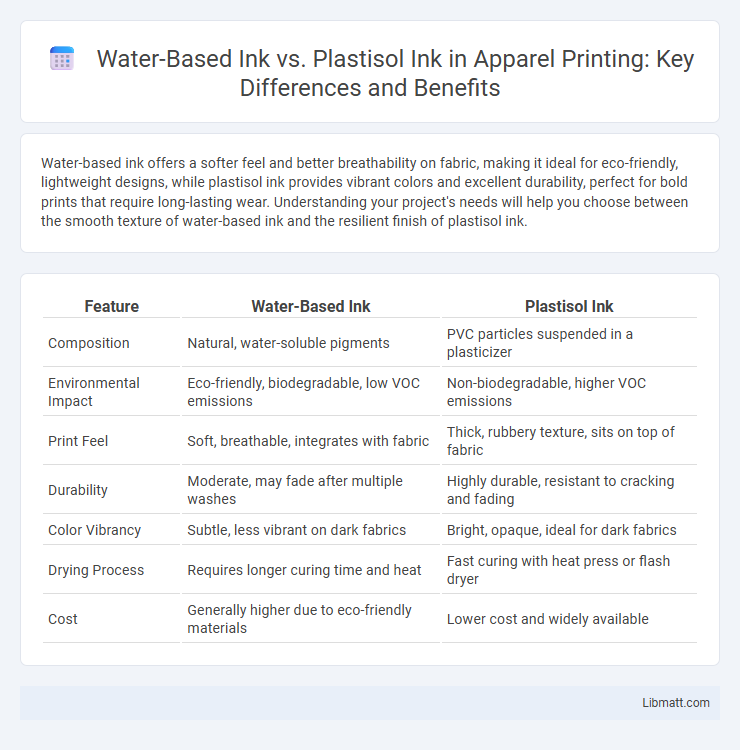

Water-based ink offers a softer feel and better breathability on fabric, making it ideal for eco-friendly, lightweight designs, while plastisol ink provides vibrant colors and excellent durability, perfect for bold prints that require long-lasting wear. Understanding your project's needs will help you choose between the smooth texture of water-based ink and the resilient finish of plastisol ink.

Table of Comparison

| Feature | Water-Based Ink | Plastisol Ink |

|---|---|---|

| Composition | Natural, water-soluble pigments | PVC particles suspended in a plasticizer |

| Environmental Impact | Eco-friendly, biodegradable, low VOC emissions | Non-biodegradable, higher VOC emissions |

| Print Feel | Soft, breathable, integrates with fabric | Thick, rubbery texture, sits on top of fabric |

| Durability | Moderate, may fade after multiple washes | Highly durable, resistant to cracking and fading |

| Color Vibrancy | Subtle, less vibrant on dark fabrics | Bright, opaque, ideal for dark fabrics |

| Drying Process | Requires longer curing time and heat | Fast curing with heat press or flash dryer |

| Cost | Generally higher due to eco-friendly materials | Lower cost and widely available |

Introduction to Water-Based and Plastisol Inks

Water-based ink is a non-toxic, eco-friendly option that penetrates fabric fibers, resulting in a soft, breathable print ideal for light-colored garments and detailed designs. Plastisol ink, composed of PVC particles suspended in a plasticizer, sits on top of the fabric, providing vibrant, durable prints with excellent opacity, especially suited for dark or heavy fabrics. Each ink type has distinct applications and drying processes, influencing garment feel, washability, and environmental impact.

Composition and Characteristics

Water-based ink consists primarily of pigments or dyes suspended in a water-soluble carrier, resulting in a thin, quick-drying formula that penetrates fabric fibers, leading to a soft and breathable print. Plastisol ink is composed of PVC particles suspended in a plasticizer, creating a thicker, more opaque layer that sits on the fabric surface and requires heat curing to solidify. Water-based inks offer environmentally friendly, flexible prints ideal for lightweight fabrics, whereas plastisol inks provide vibrant colors and durability suited for heavy-duty applications.

Print Quality and Finish

Water-based ink delivers a soft, breathable finish with vibrant colors that permeate the fabric, ideal for detailed designs and a natural feel. Plastisol ink forms a thick, durable layer on the surface, offering sharp, opaque prints with excellent color vibrancy and longevity. Your choice depends on whether you prioritize a lightweight, eco-friendly print or a highly durable, textured finish.

Application Techniques

Water-based ink penetrates fabric fibers, allowing for softer prints ideal for direct-to-garment and screen printing techniques on light-colored textiles. Plastisol ink sits on the fabric surface, providing vibrant colors and durability, commonly used in screen printing with flash curing and heat setting processes. Choosing between these inks depends on the desired print feel, fabric type, and production method efficiency.

Durability and Washability

Water-based inks offer softer prints that become part of the fabric but tend to have lower durability and may fade faster with repeated washing compared to plastisol inks. Plastisol inks provide superior durability and washability, resisting cracking and fading even after multiple laundry cycles, making them ideal for long-lasting apparel prints. Choosing the right ink depends on your priorities for softness versus long-term resilience in your printed garments.

Environmental Impact

Water-based ink offers a significantly lower environmental impact compared to plastisol ink due to its non-toxic, biodegradable composition that minimizes harmful chemical waste and air pollution. Plastisol ink contains PVC and phthalates, which release toxic fumes during curing and present challenges in disposal and recycling processes. Choosing water-based ink supports eco-friendly printing practices by reducing hazardous waste and promoting sustainable manufacturing.

Cost Considerations

Water-based ink generally incurs lower upfront costs due to simpler cleanup and less equipment wear, making it budget-friendly for small to medium print runs. Plastisol ink requires higher initial investment in materials and curing equipment but can be more cost-effective for large-scale productions due to faster curing times and durability. Evaluating print volume and product lifespan is essential to determine the most economical choice between water-based and plastisol inks.

Suitability for Different Fabrics

Water-based ink offers excellent adhesion and a soft, breathable finish ideal for natural fabrics like cotton, linen, and bamboo, ensuring vibrant prints without compromising fabric texture. Plastisol ink provides superior durability and opacity, making it suitable for synthetic fabrics and blends commonly used in athletic wear and polyester apparel. Choosing between the two depends on fabric type, desired print feel, and long-term wear requirements.

Pros and Cons Comparison

Water-based ink offers a soft, breathable print ideal for lightweight fabrics, making it environmentally friendly due to its low VOC content, but it may require longer drying times and is less vibrant on dark garments. Plastisol ink provides excellent opacity and vibrant colors, ensuring durability and ease of use with quick curing, yet it feels heavier on fabrics and contains PVC, raising environmental concerns. Your choice depends on the desired feel, fabric type, and eco-consciousness of the printing project.

Choosing the Right Ink for Your Project

Water-based ink offers a soft feel and is ideal for eco-friendly, breathable prints on light-colored fabrics, making it perfect for detailed designs and vintage looks. Plastisol ink provides vibrant colors, excellent opacity, and durability, suitable for dark garments and heavy-duty applications requiring long-lasting prints. Selecting the right ink depends on fabric type, desired texture, color vibrancy, and environmental considerations for your project.

Water-based ink vs plastisol ink Infographic

libmatt.com

libmatt.com