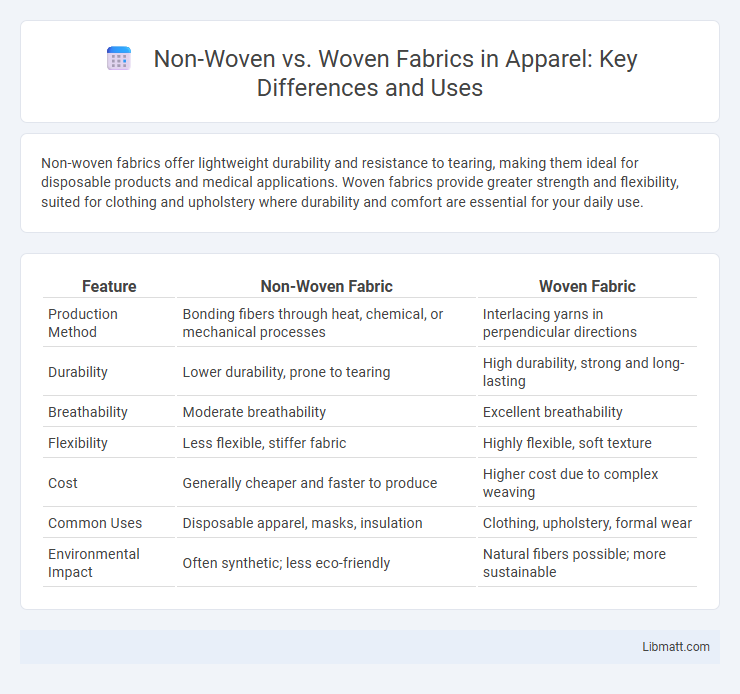

Non-woven fabrics offer lightweight durability and resistance to tearing, making them ideal for disposable products and medical applications. Woven fabrics provide greater strength and flexibility, suited for clothing and upholstery where durability and comfort are essential for your daily use.

Table of Comparison

| Feature | Non-Woven Fabric | Woven Fabric |

|---|---|---|

| Production Method | Bonding fibers through heat, chemical, or mechanical processes | Interlacing yarns in perpendicular directions |

| Durability | Lower durability, prone to tearing | High durability, strong and long-lasting |

| Breathability | Moderate breathability | Excellent breathability |

| Flexibility | Less flexible, stiffer fabric | Highly flexible, soft texture |

| Cost | Generally cheaper and faster to produce | Higher cost due to complex weaving |

| Common Uses | Disposable apparel, masks, insulation | Clothing, upholstery, formal wear |

| Environmental Impact | Often synthetic; less eco-friendly | Natural fibers possible; more sustainable |

Introduction to Non-Woven and Woven Fabrics

Non-woven fabrics are made by bonding fibers together using chemical, mechanical, heat, or solvent treatment without weaving or knitting, offering high flexibility and cost-effective production. Woven fabrics consist of interlaced yarns arranged perpendicularly on a loom, resulting in strong, durable materials commonly used in apparel and upholstery. The structural differences between non-woven and woven fabrics significantly influence their texture, strength, breathability, and application across industries such as healthcare, automotive, and fashion.

Defining Non-Woven Fabrics: Structure and Manufacturing

Non-woven fabrics consist of fibers bonded together through chemical, mechanical, heat, or solvent treatments without weaving or knitting, resulting in a uniform structure with enhanced durability and breathability. Manufactured by processes such as spunbonding, meltblowing, and needle punching, non-wovens offer versatile applications ranging from medical textiles to filtration and geotextiles. Their ability to be engineered for specific properties like absorbency, liquid repellency, and strength distinguishes them from traditional woven fabrics made from interlaced yarns.

Woven Fabrics Explained: Weaving Techniques and Properties

Woven fabrics are created by interlacing two sets of yarns at right angles, utilizing techniques such as plain, twill, and satin weaves to achieve varying textures and strengths. These weaving methods determine the fabric's durability, flexibility, and resistance to wear, making woven textiles ideal for apparel, upholstery, and industrial uses. The interlacing structure provides stability and breathability, distinguishing woven fabrics from non-woven alternatives that rely on bonding or felting processes.

Key Differences Between Non-Woven and Woven Materials

Non-woven materials are created by bonding fibers together through chemical, mechanical, or heat processes, resulting in a fabric that lacks a traditional weave or knit pattern, offering high absorbency and breathability ideal for medical and hygiene products. Woven materials are produced by interlacing two sets of yarns at right angles, providing strength, durability, and flexibility suited for apparel, upholstery, and industrial applications. The structural differences influence the performance characteristics, with non-wovens excelling in filtration and disposability, while wovens deliver enhanced tensile strength and abrasion resistance.

Applications of Non-Woven Fabrics in Industry

Non-woven fabrics are extensively used in medical applications such as surgical gowns, masks, and wound dressings due to their excellent barrier properties and breathability. In the automotive industry, they serve as insulation materials, interior linings, and filtration media, valued for their durability and lightweight nature. The construction sector utilizes non-woven fabrics for geotextiles, roofing membranes, and house wraps, where their strength and permeability enhance structural integrity and moisture control.

Popular Uses of Woven Fabrics Across Sectors

Woven fabrics are extensively used in apparel manufacturing, including shirts, dresses, and trousers, due to their durability and breathability. In the automotive industry, woven textiles reinforce airbags and seat belts, providing safety and strength. Additionally, home furnishings such as upholstery, curtains, and bedding rely on woven fabrics for their aesthetic appeal and structural integrity.

Performance: Durability, Strength, and Flexibility Comparison

Non-woven fabrics typically offer excellent flexibility and are lighter, but woven fabrics excel in durability and tensile strength due to their tightly interlaced fibers. The woven structure provides superior resistance to wear and tear, making it ideal for applications requiring long-term use and high strength. Your choice depends on whether flexibility or durability is the primary performance requirement for the specific application.

Environmental Impact: Sustainability Considerations

Non-woven fabrics often require less water and energy during production compared to woven textiles, making them a more sustainable choice in many applications. However, non-wovens are typically less durable and harder to recycle, contributing to environmental waste when disposed improperly. Woven fabrics, with their longer lifespan and higher recyclability, tend to have a lower overall environmental impact despite potentially higher initial resource consumption.

Cost Efficiency and Economic Factors

Non-woven fabrics generally offer greater cost efficiency due to their simpler manufacturing processes and lower material consumption compared to woven fabrics, resulting in reduced production costs. Woven fabrics, while typically more durable and reusable, demand higher labor and machinery investments, increasing overall expenses. Economic factors favor non-wovens for disposable or short-term applications, whereas woven textiles are more cost-effective for long-term or heavy-duty uses.

Choosing the Right Fabric: Factors to Consider

Choosing the right fabric depends on factors like durability, breathability, and application requirements. Woven fabrics offer higher strength and longevity, making them ideal for apparel and upholstery, while non-woven fabrics provide excellent filtration, water resistance, and cost-effectiveness for medical and disposable products. Consider fabric weight, texture, and environmental impact to ensure optimal performance and sustainability.

Non-woven vs woven Infographic

libmatt.com

libmatt.com