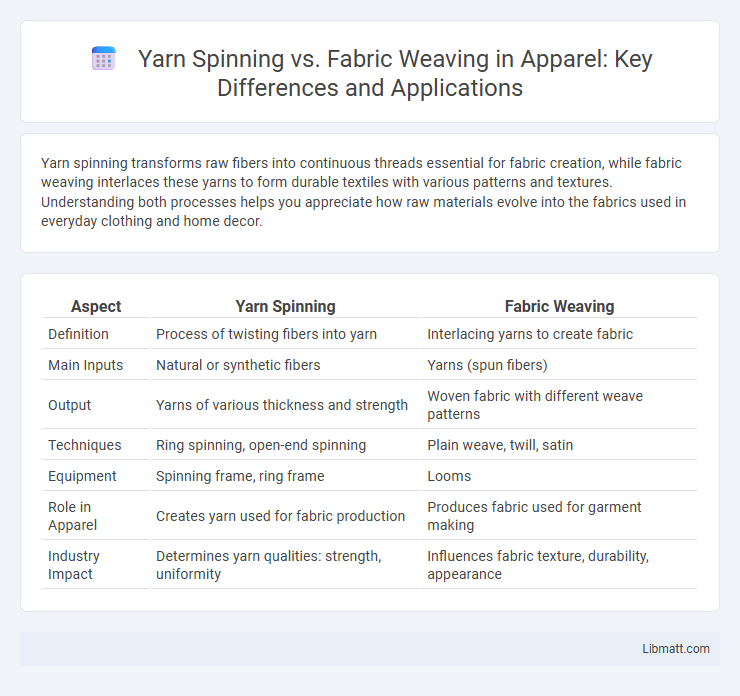

Yarn spinning transforms raw fibers into continuous threads essential for fabric creation, while fabric weaving interlaces these yarns to form durable textiles with various patterns and textures. Understanding both processes helps you appreciate how raw materials evolve into the fabrics used in everyday clothing and home decor.

Table of Comparison

| Aspect | Yarn Spinning | Fabric Weaving |

|---|---|---|

| Definition | Process of twisting fibers into yarn | Interlacing yarns to create fabric |

| Main Inputs | Natural or synthetic fibers | Yarns (spun fibers) |

| Output | Yarns of various thickness and strength | Woven fabric with different weave patterns |

| Techniques | Ring spinning, open-end spinning | Plain weave, twill, satin |

| Equipment | Spinning frame, ring frame | Looms |

| Role in Apparel | Creates yarn used for fabric production | Produces fabric used for garment making |

| Industry Impact | Determines yarn qualities: strength, uniformity | Influences fabric texture, durability, appearance |

Introduction to Yarn Spinning and Fabric Weaving

Yarn spinning transforms raw fibers such as cotton, wool, or synthetic materials into continuous threads by twisting and drawing, which serves as the foundational step in textile production. Fabric weaving intertwines two sets of yarns, warp and weft, at right angles to create a structured fabric with varying patterns and textures. Both processes are crucial in textile manufacturing, with spinning determining the yarn's strength and texture and weaving establishing the fabric's durability and design.

Defining Yarn Spinning: Process and Purpose

Yarn spinning is the process of twisting fibers such as cotton, wool, or synthetic materials to create continuous strands of yarn essential for textile production. This technique transforms raw fibers into a strong, uniform thread that serves as the foundation for fabric weaving and knitting. Understanding yarn spinning helps you appreciate the quality and texture of the fabrics derived from these spun yarns in various applications.

Understanding Fabric Weaving: Methods and Applications

Fabric weaving involves interlacing two distinct sets of yarns--warp and weft--at right angles to create textiles with varied textures and strengths. Common weaving methods include plain weave, twill, and satin, each offering unique applications ranging from durable denim to luxurious silk fabrics. This process is essential in producing materials used in fashion, upholstery, and industrial textiles, emphasizing the importance of method selection for specific fabric properties.

Key Differences Between Yarn Spinning and Fabric Weaving

Yarn spinning is the process of twisting fibers together to form yarn, while fabric weaving involves interlacing two sets of yarns at right angles to create fabric. Spinning focuses on preparing long, continuous threads from raw fibers such as cotton, wool, or synthetic materials, essential for the texture and strength of the yarn. Weaving determines the fabric's pattern, density, and durability by controlling the warp and weft yarns' arrangement on a loom.

Raw Materials Used in Spinning vs Weaving

Yarn spinning primarily uses raw fibers such as cotton, wool, flax, or synthetic filaments like polyester and nylon, transforming them into continuous threads through processes like carding and twisting. Fabric weaving utilizes these spun yarns, which can be made from natural or synthetic fibers, interlacing them on a loom to create textiles with various patterns and textures. The quality and type of raw material in spinning directly influence the strength, texture, and durability of the woven fabric produced.

Technologies and Equipment in Spinning and Weaving

Yarn spinning employs advanced technologies such as ring spinning, open-end spinning, and air-jet spinning machines, which efficiently convert fibers into yarn with varying thickness and strength. Fabric weaving involves sophisticated looms like rapier, air-jet, and projectile looms, enabling the interlacing of warp and weft threads to create diverse fabric structures. Your choice between spinning and weaving relies on understanding how these specialized machines impact production speed, fabric quality, and texture.

Impact on Textile Quality and Texture

Yarn spinning determines the strength, uniformity, and fineness of the yarn, directly influencing the fabric's durability and smoothness. Fabric weaving patterns, such as plain, twill, or satin weave, control the texture, flexibility, and visual appeal of the final textile. The combined quality of spun yarn and chosen weaving technique ultimately defines the fabric's performance characteristics and tactile experience.

Sustainability and Environmental Considerations

Yarn spinning and fabric weaving have distinct environmental impacts, with yarn spinning often consuming more energy and water due to fiber preparation and twisting processes. Fabric weaving, while generally less resource-intensive per unit, can generate textile waste and chemical runoff from dyeing and finishing stages. Your choice between these methods should consider sustainable materials and eco-friendly technologies to minimize carbon footprint and water pollution.

Industrial Applications: Spinning vs Weaving

Industrial applications of yarn spinning predominantly focus on producing consistent, high-quality yarns crucial for textile manufacturing, allowing customization in thickness, strength, and fiber blend to meet diverse product requirements. Fabric weaving transforms these yarns into structured textiles used in sectors such as apparel, upholstery, automotive interiors, and technical fabrics, emphasizing durability and design complexity. Advances in automated spinning and weaving technologies enhance production efficiency, precision, and scalability across industries demanding specific fabric properties and performance standards.

Future Trends in Yarn Spinning and Fabric Weaving

Emerging technologies like AI-driven automation and sustainable fiber innovations are transforming yarn spinning by enhancing production efficiency and reducing environmental impact. Fabric weaving is rapidly evolving with smart textiles and 3D weaving techniques, enabling the creation of highly functional and customizable fabrics for diverse industries. Your understanding of these future trends will position you to leverage advancements that improve quality and sustainability in textile manufacturing.

Yarn Spinning vs Fabric Weaving Infographic

libmatt.com

libmatt.com