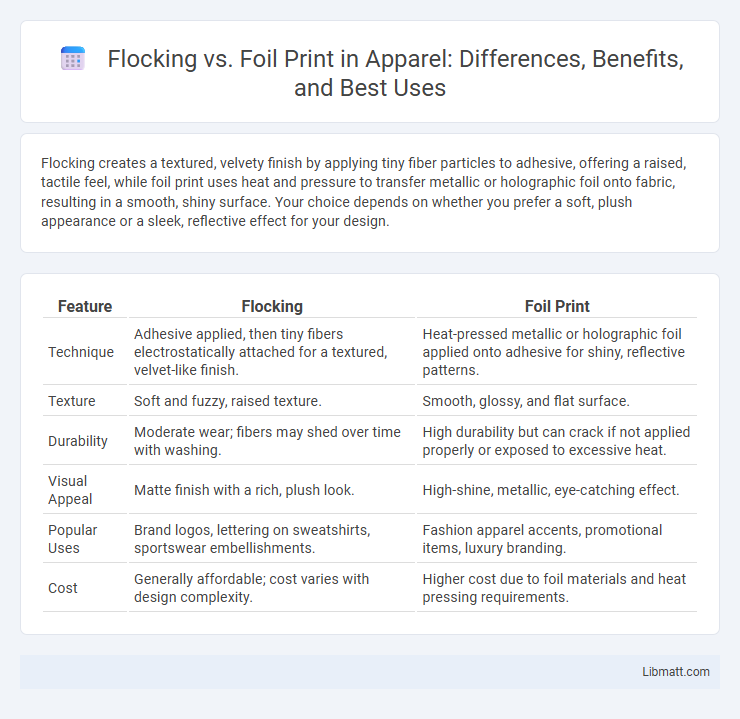

Flocking creates a textured, velvety finish by applying tiny fiber particles to adhesive, offering a raised, tactile feel, while foil print uses heat and pressure to transfer metallic or holographic foil onto fabric, resulting in a smooth, shiny surface. Your choice depends on whether you prefer a soft, plush appearance or a sleek, reflective effect for your design.

Table of Comparison

| Feature | Flocking | Foil Print |

|---|---|---|

| Technique | Adhesive applied, then tiny fibers electrostatically attached for a textured, velvet-like finish. | Heat-pressed metallic or holographic foil applied onto adhesive for shiny, reflective patterns. |

| Texture | Soft and fuzzy, raised texture. | Smooth, glossy, and flat surface. |

| Durability | Moderate wear; fibers may shed over time with washing. | High durability but can crack if not applied properly or exposed to excessive heat. |

| Visual Appeal | Matte finish with a rich, plush look. | High-shine, metallic, eye-catching effect. |

| Popular Uses | Brand logos, lettering on sweatshirts, sportswear embellishments. | Fashion apparel accents, promotional items, luxury branding. |

| Cost | Generally affordable; cost varies with design complexity. | Higher cost due to foil materials and heat pressing requirements. |

Understanding Flocking and Foil Printing

Flocking involves applying tiny fibers to a surface to create a textured, velvet-like finish, enhancing tactile appeal and depth on fabrics or paper. Foil printing uses heat and pressure to transfer metallic or pigmented foil onto a substrate, producing a shiny, reflective effect often used for branding and decorative detailing. Both techniques elevate design impact but differ significantly in texture, appearance, and material compatibility.

Key Differences Between Flocking and Foil Print

Flocking involves applying tiny fibers to a surface to create a textured, velvet-like finish, while foil printing uses heat and pressure to transfer a shiny metallic or holographic foil onto materials, resulting in a smooth and reflective surface. Flocking offers a tactile, raised effect suitable for fabric customization and packaging, whereas foil print enhances visual appeal with glossy, eye-catching accents commonly used in invitations, branding, and labels. Durability varies as flocking provides a soft, durable texture resistant to wear, whereas foil print can be prone to peeling or cracking without proper application or protection.

Flocking Print: Definition and Process

Flocking print involves applying tiny fiber particles to a fabric surface using an adhesive, creating a textured, velvety feel and a raised design. This process starts with screen printing the adhesive onto the desired areas, followed by electrostatically or mechanically applying the fibers to stick firmly, resulting in a durable and tactile finish. Flocking print is widely used in fashion and interior design to add depth and a luxurious touch compared to smooth foil print.

Foil Print: Definition and Technique

Foil print is a decorative printing technique that applies metallic or pigmented foil onto a surface using heat and pressure, creating a shiny, reflective design. This process involves a heat press machine that transfers foil from a carrier film onto fabric, paper, or other materials, resulting in vibrant, eye-catching graphics. Foil printing is commonly used for fashion, packaging, and branding to add luxury and depth to the final product.

Material Suitability: Flocking vs Foil Print

Flocking uses tiny fibers adhering to adhesive, ideal for fabrics like cotton, polyester, and velvet, creating a soft, textured finish suited for apparel and accessories. Foil print involves heat-transferring shiny metallic or matte films, best on smooth, non-porous materials such as polyester blends, nylon, and certain cotton fabrics, delivering a bold, reflective appearance. Your choice depends on the desired tactile effect and fabric compatibility, with flocking offering a velvety feel and foil print providing vibrant, eye-catching designs.

Visual Effects: Texture and Appearance Comparison

Flocking creates a raised, velvety texture that adds depth and softness to your design, making it ideal for tactile branding elements. Foil print offers a smooth, reflective surface with a metallic sheen that catches light for a glossy, eye-catching appearance. Both methods enhance visual appeal but differ significantly in texture, with flocking emphasizing texture and foil focusing on shine.

Durability and Longevity of Prints

Flocking prints offer a textured, velvety finish with moderate durability, suitable for garments that require a softer feel but often show wear after repeated washing. Foil prints provide a shiny, metallic appearance with superior durability and resistance to cracking, making them ideal for long-lasting, high-impact designs. Both methods require proper care, but foil printing generally maintains its vibrant look and structural integrity longer under regular wear and washing conditions.

Cost Considerations for Flocking and Foil Print

Flocking typically incurs higher costs due to the specialized materials and intricate application process involved in creating a textured, velvety finish. Foil print, while more budget-friendly, uses metallic or pigmented foils applied with heat, offering a shiny, reflective effect that is less labor-intensive. Your choice between these methods should factor in budget constraints and the desired tactile or visual impact on the final product.

Ideal Applications and Industry Usage

Flocking excels in applications requiring a velvet-like texture and enhanced durability, such as automotive interiors, apparel, and home decor, where tactile appeal is crucial. Foil print is ideal for high-impact visual designs on packaging, promotional materials, and luxury branding due to its reflective, metallic finish. Your choice between flocking and foil print depends on whether you prioritize texture and durability or visual shine and sophistication.

Choosing Between Flocking and Foil Print

Choosing between flocking and foil print depends on the desired texture and visual impact; flocking offers a soft, velvety feel ideal for tactile designs, while foil print delivers a shiny, metallic finish that enhances brightness and contrast. Flocking is suitable for creating a rich, matte surface with a three-dimensional effect, often used in luxury fashion and branding applications, whereas foil print excels in adding eye-catching elements on packaging and promotional materials. Consider the product type, budget, and intended audience when selecting the technique to ensure the best combination of durability and aesthetic appeal.

flocking vs foil print Infographic

libmatt.com

libmatt.com