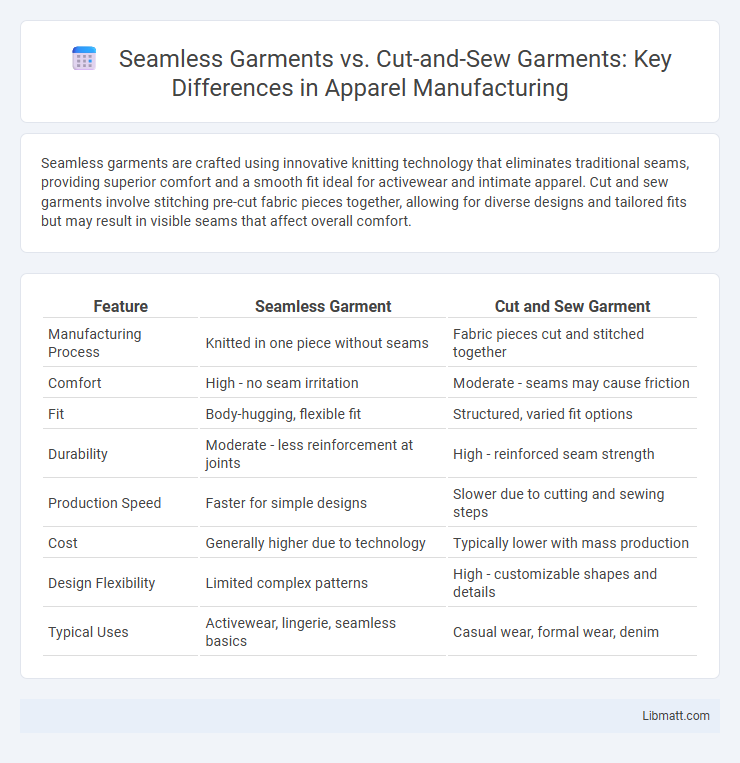

Seamless garments are crafted using innovative knitting technology that eliminates traditional seams, providing superior comfort and a smooth fit ideal for activewear and intimate apparel. Cut and sew garments involve stitching pre-cut fabric pieces together, allowing for diverse designs and tailored fits but may result in visible seams that affect overall comfort.

Table of Comparison

| Feature | Seamless Garment | Cut and Sew Garment |

|---|---|---|

| Manufacturing Process | Knitted in one piece without seams | Fabric pieces cut and stitched together |

| Comfort | High - no seam irritation | Moderate - seams may cause friction |

| Fit | Body-hugging, flexible fit | Structured, varied fit options |

| Durability | Moderate - less reinforcement at joints | High - reinforced seam strength |

| Production Speed | Faster for simple designs | Slower due to cutting and sewing steps |

| Cost | Generally higher due to technology | Typically lower with mass production |

| Design Flexibility | Limited complex patterns | High - customizable shapes and details |

| Typical Uses | Activewear, lingerie, seamless basics | Casual wear, formal wear, denim |

Introduction to Seamless and Cut and Sew Garments

Seamless garments are produced using circular knitting technology, creating a single, continuous piece of fabric without seams, which enhances comfort, fit, and durability. Cut and sew garments involve fabric pieces cut individually and stitched together, allowing for intricate designs, varied fabrics, and precise tailoring. Your choice between seamless and cut and sew garments depends on the desired fit, design complexity, and production efficiency.

What Are Seamless Garments?

Seamless garments are created using advanced knitting technology that produces a garment in a single piece without stitched seams, enhancing comfort and flexibility. These garments reduce friction and chafing, making them ideal for activewear and performance clothing. The seamless construction also offers a sleek, form-fitting silhouette and improved durability compared to traditional cut and sew garments.

What Are Cut and Sew Garments?

Cut and sew garments are clothing items created by cutting fabric pieces according to individual patterns and sewing them together to achieve the desired shape and fit. This method allows for extensive customization in design, fabric choices, and construction details, making it ideal for tailored apparel. Unlike seamless garments produced through knitting or molding technology, cut and sew techniques rely on traditional sewing processes, offering greater versatility in styles and complex garment structures.

Key Differences Between Seamless and Cut and Sew Garments

Seamless garments are produced using circular knitting machines that create a continuous tube of fabric without any side seams, enhancing comfort and fit by reducing irritation and improving stretchability. Cut and sew garments are made by cutting fabric pieces and sewing them together, allowing for more complex designs, diverse fabric combinations, and tailored fits but potentially causing more seams and reduced flexibility. The key difference lies in manufacturing techniques, where seamless offers smooth construction and cut and sew provides design versatility.

Manufacturing Process: Seamless vs Cut and Sew

Seamless garments are produced using advanced circular knitting machines that create the entire piece in one continuous form, eliminating the need for stitching and reducing fabric waste. Cut and sew garments involve cutting fabric panels from rolls and sewing them together, allowing for more complex designs but generating more material offcuts and requiring multiple assembly steps. The seamless manufacturing process enhances garment durability and comfort by minimizing seams, while cut and sew offers versatility in styles and size customization.

Comfort and Fit Comparison

Seamless garments offer superior comfort due to their lack of stitches and smooth construction, reducing irritation and friction on the skin. Cut and sew garments provide a more tailored fit through precise pattern cutting and stitching, allowing for customizable sizing and design variations. While seamless designs excel in stretch and flexibility, cut and sew pieces deliver enhanced structure and contouring for a polished appearance.

Durability and Strength Analysis

Seamless garments exhibit enhanced durability and strength due to their continuous fabric construction, which eliminates stress points caused by seams, reducing the risk of tearing and wear. Cut and sew garments, while offering design flexibility, rely on stitched seams that can weaken over time under repeated strain or abrasion. Advanced textile engineering in seamless manufacturing provides superior tensile strength and elasticity compared to traditional cut and sew techniques, making seamless apparel more resilient for activewear and performance applications.

Design Flexibility and Aesthetic Options

Seamless garments offer limited design flexibility due to their tubular construction, primarily suited for simple, form-fitting styles without seams. Cut and sew garments provide extensive aesthetic options, allowing for diverse patterns, textures, and structural elements through separate fabric pieces sewn together. Designers favor cut and sew techniques to achieve complex shapes and detailed customizations that are unattainable with seamless knitting technology.

Environmental Impact and Sustainability

Seamless garments reduce fabric waste by eliminating the need for cutting and sewing individual pieces, resulting in a lower environmental footprint compared to traditional cut and sew garments. This manufacturing process uses less water and energy, contributing to enhanced sustainability in textile production. By choosing seamless garments, Your wardrobe supports eco-friendly practices that minimize resource consumption and textile waste.

Which Garment Type Is Best for You?

Seamless garments offer superior comfort and flexibility, ideal for activewear and athleisure due to their minimal stitching and reduced irritation. Cut and sew garments provide greater design versatility and detailed construction, making them perfect for fashion-forward styles and tailored fits. Selecting the best garment type depends on your priority for comfort and performance versus design intricacy and customization.

Seamless Garment vs Cut and Sew Garment Infographic

libmatt.com

libmatt.com