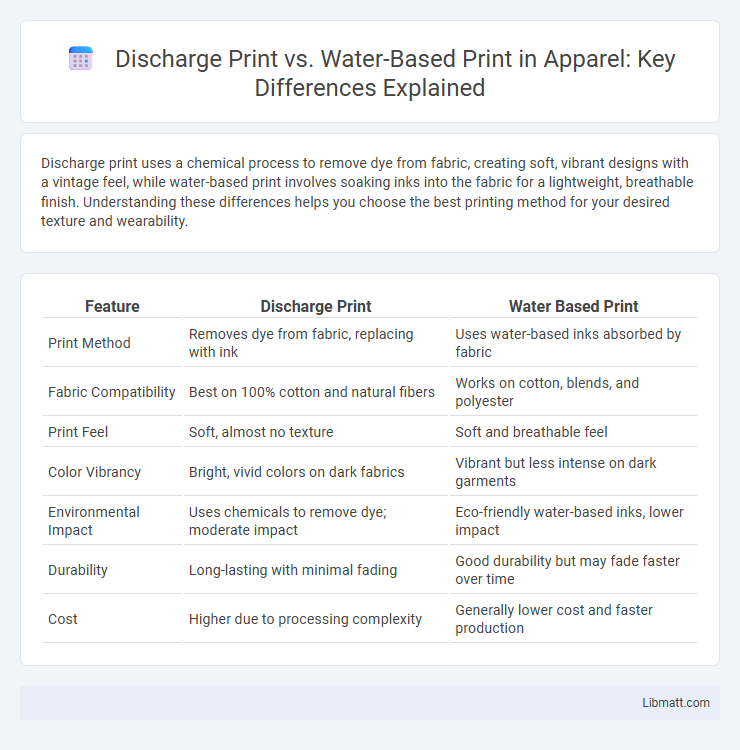

Discharge print uses a chemical process to remove dye from fabric, creating soft, vibrant designs with a vintage feel, while water-based print involves soaking inks into the fabric for a lightweight, breathable finish. Understanding these differences helps you choose the best printing method for your desired texture and wearability.

Table of Comparison

| Feature | Discharge Print | Water Based Print |

|---|---|---|

| Print Method | Removes dye from fabric, replacing with ink | Uses water-based inks absorbed by fabric |

| Fabric Compatibility | Best on 100% cotton and natural fibers | Works on cotton, blends, and polyester |

| Print Feel | Soft, almost no texture | Soft and breathable feel |

| Color Vibrancy | Bright, vivid colors on dark fabrics | Vibrant but less intense on dark garments |

| Environmental Impact | Uses chemicals to remove dye; moderate impact | Eco-friendly water-based inks, lower impact |

| Durability | Long-lasting with minimal fading | Good durability but may fade faster over time |

| Cost | Higher due to processing complexity | Generally lower cost and faster production |

Introduction to Discharge Printing and Water Based Printing

Discharge printing uses a chemical process to remove dye from fabric, creating soft, vibrant designs with a vintage feel, while water-based printing applies pigmented inks that soak into the fabric for a lightweight, breathable finish. This method makes your custom apparel feel softer and more comfortable compared to traditional plastisol prints. Understanding the differences helps you choose the best printing technique to achieve your desired aesthetic and wearability.

How Discharge Printing Works

Discharge printing works by using a water-based ink containing reducing agents that remove the fabric's original dye, creating a soft, vibrant print with a natural feel. The process involves applying the discharge paste to dyed garments, then curing them with heat to activate the chemical reaction that removes color where applied. Your choice of discharge print results in vivid, breathable designs ideal for darker fabrics, differentiating it from typical water-based prints that sit on the fabric's surface.

How Water Based Printing Works

Water based printing uses water-based inks that penetrate the fabric fibers, resulting in soft, breathable prints that maintain garment flexibility. The process involves applying a water-soluble ink that bonds with the textile, allowing vibrant colors to emerge without the heavy feel of plastisol inks. This eco-friendly method is ideal for achieving detailed designs on light and dark fabrics while preserving the material's natural texture.

Key Differences Between Discharge and Water Based Prints

Discharge print uses a chemical process to remove dye from fabric, creating soft, vibrant designs with a vintage feel, while water-based print deposits ink directly onto the fabric's surface for a lighter, eco-friendly finish. Discharge printing works best on darker, 100% cotton garments, producing a smooth texture without added weight, whereas water-based printing suits both light and dark fabrics with a slightly raised feel. Your choice depends on desired softness, durability, and environmental considerations, as discharge offers a unique softness and longevity while water-based inks prioritize breathability and sustainability.

Advantages of Discharge Printing

Discharge printing offers vibrant, soft designs by removing the fabric's dye rather than adding ink, resulting in a smooth, breathable finish ideal for apparel. This method is highly durable, maintaining color brightness and detail even after repeated washes, which enhances the garment's longevity. Your high-quality textiles benefit from discharge printing's eco-friendly process that uses fewer chemicals and water compared to traditional water-based prints.

Advantages of Water Based Printing

Water based printing offers eco-friendly benefits due to its low volatile organic compounds (VOC) and water-soluble inks, making it safer for both users and the environment. It provides a softer hand feel and vibrant colors that penetrate fabric fibers deeply without clogging screens, resulting in durable, long-lasting prints. You can achieve excellent breathability and comfort in garments, ideal for sustainable and high-quality textile production.

Limitations and Challenges of Each Method

Discharge print struggles with limited fabric compatibility, primarily working best on dark, cotton-based materials, while it may result in uneven color removal or less vibrant designs on synthetic blends. Water based print faces challenges in drying time and durability, as the ink can be less vibrant and may fade or crack over time, especially on darker fabrics. Your choice depends on balancing the need for vibrant, soft prints with considerations of fabric type and long-term wear.

Best Fabrics for Discharge vs Water Based Printing

Discharge print works best on 100% cotton fabrics as it removes the garment's dye to create vibrant, soft designs, making it ideal for natural fibers that absorb the bleach-based discharge paste effectively. Water-based print performs well on both cotton and cotton-poly blends, providing a softer hand feel and eco-friendly finish, especially suited for lighter-colored fabrics where the ink soaks in rather than sitting on the surface. Choosing the right fabric for your project ensures the print's durability and visual impact, with discharge printing excelling on natural fibers and water-based printing offering versatility across multiple fabric types.

Environmental Impact: Discharge vs Water Based Inks

Discharge print uses chemical agents to remove dye from fabric, reducing the need for additional pigments and resulting in less water pollution compared to water based inks, which rely on water-soluble pigments and can generate wastewater containing micro-particles. Water based inks are generally considered safer for the environment due to non-toxic, biodegradable components, but their extensive water use during application and cleaning may increase environmental footprint. Your choice between discharge and water based prints should consider the balance between chemical use and water consumption to minimize environmental impact.

Choosing the Right Print Method for Your Project

Discharge Print offers vibrant, soft designs by removing dye from fabric, making it ideal for dark garments requiring a vintage look, while Water Based Print infuses ink into the fibers, producing eco-friendly, breathable prints perfect for lightweight or pastel fabrics. Your project's fabric type, desired durability, and print feel determine the best method; discharge printing excels in softness and brightness on cotton, whereas water based printing ensures seamless integration with minimal environmental impact. Consider the end-use and design complexity to select the print that balances aesthetic appeal with functional performance.

Discharge Print vs Water Based Print Infographic

libmatt.com

libmatt.com