Puff print creates a raised, three-dimensional texture by using heat to expand ink on fabric, offering a bold and tactile design, while flock print uses tiny fibers glued to the fabric surface for a velvety, soft texture with a matte finish. Choosing between puff and flock print depends on your desired visual effect and fabric feel, with puff providing a plump, eye-catching look and flock delivering a smooth, textured touch.

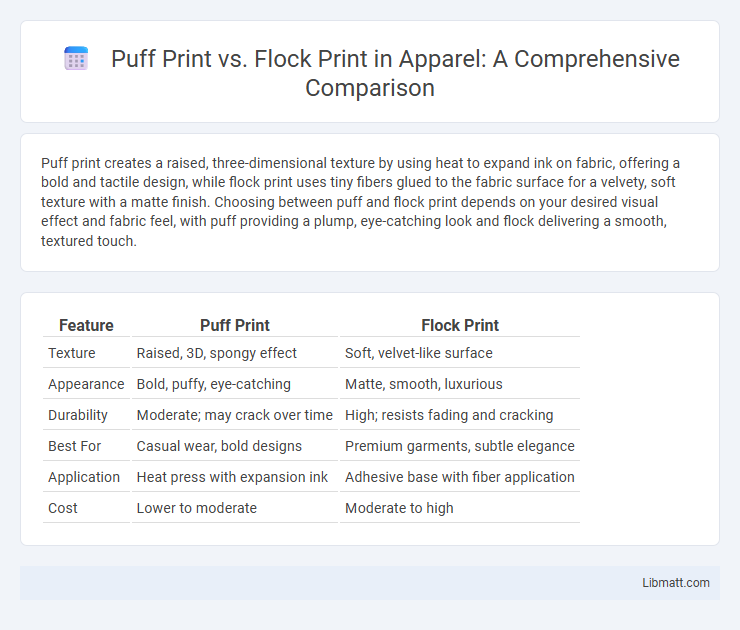

Table of Comparison

| Feature | Puff Print | Flock Print |

|---|---|---|

| Texture | Raised, 3D, spongy effect | Soft, velvet-like surface |

| Appearance | Bold, puffy, eye-catching | Matte, smooth, luxurious |

| Durability | Moderate; may crack over time | High; resists fading and cracking |

| Best For | Casual wear, bold designs | Premium garments, subtle elegance |

| Application | Heat press with expansion ink | Adhesive base with fiber application |

| Cost | Lower to moderate | Moderate to high |

Introduction to Puff Print and Flock Print

Puff print creates a raised, three-dimensional effect by applying heat-activated ink that expands on fabric, resulting in a soft, textured design. Flock print uses tiny fiber particles adhered to the surface, producing a velvety, matte finish with a plush feel and distinct texture. Understanding these techniques helps your apparel or product designs stand out with unique tactile qualities and visual interest.

Understanding the Basics: What is Puff Printing?

Puff printing is a heat-activated process that creates a raised, three-dimensional effect on fabric by using a special foam additive in the ink that expands when heated. Unlike traditional flat screen printing, puff prints add texture and depth, making designs more visually striking and tactile. This technique is commonly used in apparel decoration to enhance logos, text, and graphic elements with a bold and dynamic appearance.

What is Flock Printing? An Overview

Flock printing involves applying tiny fiber particles to a surface using adhesive, creating a raised, velvety texture that enhances tactile and visual appeal. This method is popular for adding dimension and softness to garments, making your designs stand out with a unique, fuzzy finish. Compared to puff print, flock printing offers a distinct texture that feels plush rather than puffy or inflated.

Key Differences Between Puff Print and Flock Print

Puff print creates a raised, three-dimensional effect by using a heat-activated additive that expands during pressing, giving designs a soft, puffy texture. Flock print applies tiny fibers to a sticky base, resulting in a velvety, textured finish with a smooth, fabric-like feel. Your choice between puff and flock print depends on whether you prefer a bold, dimensional look or a soft, tactile surface for your apparel or merchandise.

Material Compatibility: Which Fabrics Perform Best?

Puff print works best on smooth, tightly woven fabrics like cotton and polyester blends, allowing the ink to rise and create a raised, textured effect. Flock print requires fabrics with some surface texture like fleece, terry, or cotton knit to properly adhere the tiny fibers, producing a velvety, suede-like finish. Both methods perform poorly on fabrics with loose weaves or high stretch, such as mesh or spandex, where the print durability and texture can be compromised.

Visual and Textural Effects: Comparing Final Results

Puff print creates raised, three-dimensional designs with a soft, puffy texture that adds depth and a tactile feel to your garments, making graphics more eye-catching. Flock print produces a velvet-like, fuzzy surface that offers a smooth, luxurious texture and rich color vibrancy, suitable for elegant and refined looks. Choosing between puff and flock print depends on whether you prefer a bold, textured pop or a soft, plush finish for your apparel's visual and textural effects.

Durability and Maintenance Considerations

Puff print offers moderate durability with its raised texture, though it can crack or peel after repeated washing if not properly cared for. Flock print provides superior durability due to its velvety, fabric-like surface that withstands numerous wash cycles while maintaining softness and shape. For maintenance, puff prints require gentle washing inside out and low heat drying to prolong lifespan, whereas flock prints benefit from similar gentle care but are less prone to damage from wear and tear.

Cost Analysis: Puff Print vs Flock Print

Puff print typically incurs lower production costs due to its simpler application process and faster curing times, making it ideal for bulk orders with budget constraints. In contrast, flock print involves higher expenses because of specialized adhesive materials and the additional step of applying the fuzzy texture, increasing labor and production time. Businesses seeking premium finishes might justify flock print's cost elevation by its durability and tactile appeal, while cost-sensitive projects often favor puff print for economic efficiency.

Ideal Applications for Puff and Flock Printing

Puff print is ideal for adding a raised, three-dimensional texture to casual wear like t-shirts, hoodies, and sports apparel, enhancing visual interest and tactile appeal. Flock printing excels in creating a soft, velvety surface perfect for luxury garments, branding on hats, and detailed logos requiring a premium feel. Your choice depends on whether you want bold, puffy designs or smooth, plush textures to complement the fabric and style.

Choosing the Right Technique for Your Project

Puff print creates a raised, three-dimensional texture by expanding ink during the curing process, ideal for bold graphic designs that require tactile impact and durability on cotton or polyester fabrics. Flock print uses adhesive and fine fiber particles to produce a velvety, soft texture, perfect for intricate details and designs needing a luxurious, velvet-like finish on various fabric types. Selecting the right technique depends on the project's design complexity, fabric compatibility, and desired texture effect to ensure optimal visual appeal and longevity.

Puff Print vs Flock Print Infographic

libmatt.com

libmatt.com