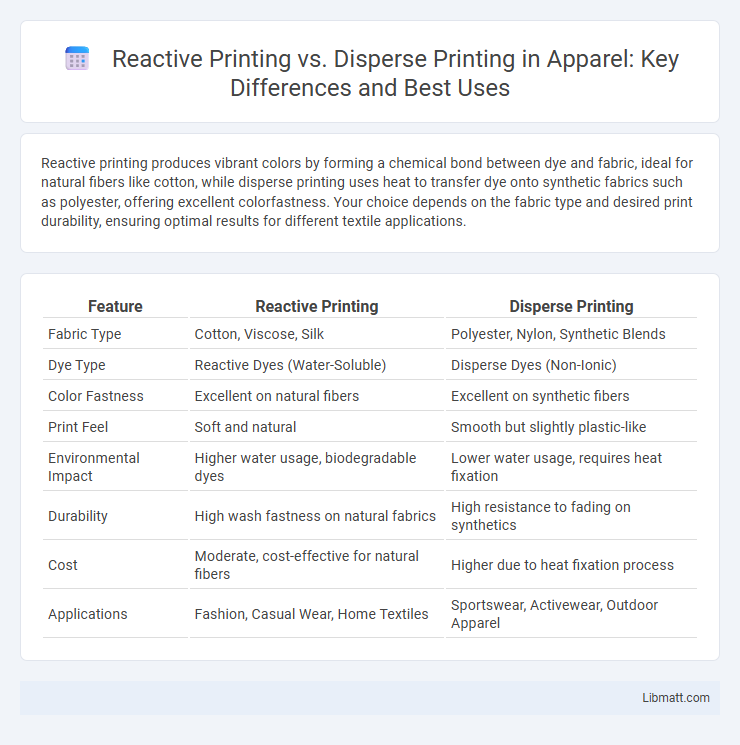

Reactive printing produces vibrant colors by forming a chemical bond between dye and fabric, ideal for natural fibers like cotton, while disperse printing uses heat to transfer dye onto synthetic fabrics such as polyester, offering excellent colorfastness. Your choice depends on the fabric type and desired print durability, ensuring optimal results for different textile applications.

Table of Comparison

| Feature | Reactive Printing | Disperse Printing |

|---|---|---|

| Fabric Type | Cotton, Viscose, Silk | Polyester, Nylon, Synthetic Blends |

| Dye Type | Reactive Dyes (Water-Soluble) | Disperse Dyes (Non-Ionic) |

| Color Fastness | Excellent on natural fibers | Excellent on synthetic fibers |

| Print Feel | Soft and natural | Smooth but slightly plastic-like |

| Environmental Impact | Higher water usage, biodegradable dyes | Lower water usage, requires heat fixation |

| Durability | High wash fastness on natural fabrics | High resistance to fading on synthetics |

| Cost | Moderate, cost-effective for natural fibers | Higher due to heat fixation process |

| Applications | Fashion, Casual Wear, Home Textiles | Sportswear, Activewear, Outdoor Apparel |

Introduction to Textile Printing Methods

Reactive printing uses reactive dyes that chemically bond with cellulose fibers, providing vibrant colors and excellent wash-fastness on cotton and other cellulosic fabrics. Disperse printing employs disperse dyes, which are ideal for synthetic fibers like polyester, offering good color fastness and brightness through dye diffusion into the fiber. Selecting the right technique ensures Your textile products achieve the desired appearance, durability, and fabric compatibility.

Overview of Reactive Printing

Reactive printing involves the use of reactive dyes that chemically bond with cellulose fibers, creating vibrant, long-lasting colors ideal for cotton and other natural fabrics. This method offers excellent colorfastness to washing and light, making it a preferred choice for high-quality textile prints. The process requires careful control of temperature and pH to ensure optimal dye fixation and fabric integrity.

Overview of Disperse Printing

Disperse printing uses disperse dyes primarily on synthetic fibers such as polyester, delivering vibrant colors through a sublimation process where the dye penetrates the fabric. This method offers excellent color fastness, making it suitable for activewear and sports apparel that require durability and resistance to washing and light exposure. Compared to reactive printing, disperse printing is less suitable for natural fibers but excels in producing detailed, long-lasting prints on polyester textiles.

Key Differences Between Reactive and Disperse Printing

Reactive printing uses water-based reactive dyes that chemically bond with cellulose fibers, offering vibrant colors and excellent wash fastness, ideal for cotton and other natural fibers. Disperse printing employs disperse dyes that sublimate into synthetic fibers like polyester, providing high durability and colorfastness on hydrophobic fabrics. Key differences include fiber compatibility--reactive for natural fibers and disperse for synthetics--and the dyeing process, with reactive dyes forming covalent bonds and disperse dyes relying on heat transfer.

Fabric Compatibility: Reactive vs Disperse Printing

Reactive printing is primarily compatible with natural fibers such as cotton, linen, and silk due to its dye chemistry that forms strong covalent bonds with cellulose fibers. Disperse printing is best suited for synthetic fabrics like polyester and nylon, as its dye particles penetrate hydrophobic fibers through sublimation. The selection between reactive and disperse printing depends on the fiber type to achieve optimal color fastness and vibrancy.

Color Vibrancy and Fastness Comparison

Reactive printing delivers superior color vibrancy by chemically bonding dyes to fibers, resulting in rich, long-lasting hues on natural textiles like cotton. Disperse printing provides excellent fastness on synthetic fabrics such as polyester, ensuring colors remain vivid and resistant to fading from washing and light exposure. Your choice depends on fabric type, with reactive printing favored for brilliant colors on natural fibers and disperse printing excelling in durability on synthetics.

Environmental Impact and Sustainability

Reactive printing uses water-based dyes that bond chemically with natural fibers, resulting in vibrant colors and excellent wash fastness while generating less wastewater compared to disperse printing. Disperse printing primarily applies to synthetic fibers using disperse dyes in high-temperature processes that consume more energy and often involve harmful chemicals, increasing environmental footprints. Choosing reactive printing for your textiles supports sustainability goals by reducing chemical use and water pollution, making it a greener option in the fabric printing industry.

Cost Implications and Production Efficiency

Reactive printing typically involves higher upfront costs due to expensive reactive dyes and water-intensive processes, but it offers vibrant colors and strong fabric durability suited for cotton. Disperse printing tends to be more cost-effective for polyester fabrics, benefiting from lower dye costs and faster drying times, which enhances production efficiency. Your choice between these methods should consider fabric type and scale, as disperse printing often reduces lead times and energy consumption compared to the more resource-heavy reactive printing process.

Common Applications in the Textile Industry

Reactive printing is commonly used for cotton and other cellulose fibers, providing vibrant, long-lasting colors ideal for apparel, home textiles, and fashion fabrics. Disperse printing targets synthetic fibers such as polyester, making it a preferred method for sportswear, activewear, and upholstery due to its excellent colorfastness and durability. Your choice between these methods depends on the fabric type and end-use requirements within the textile industry.

Choosing the Right Printing Method for Your Needs

Reactive printing offers vibrant colors and excellent wash fastness on natural fibers like cotton, making it ideal for high-quality, long-lasting prints. Disperse printing works best on synthetic fabrics such as polyester, providing durable, vivid designs with excellent color penetration. Choosing the right printing method depends on your fabric type and the desired durability, ensuring optimal results for your textile projects.

Reactive Printing vs Disperse Printing Infographic

libmatt.com

libmatt.com