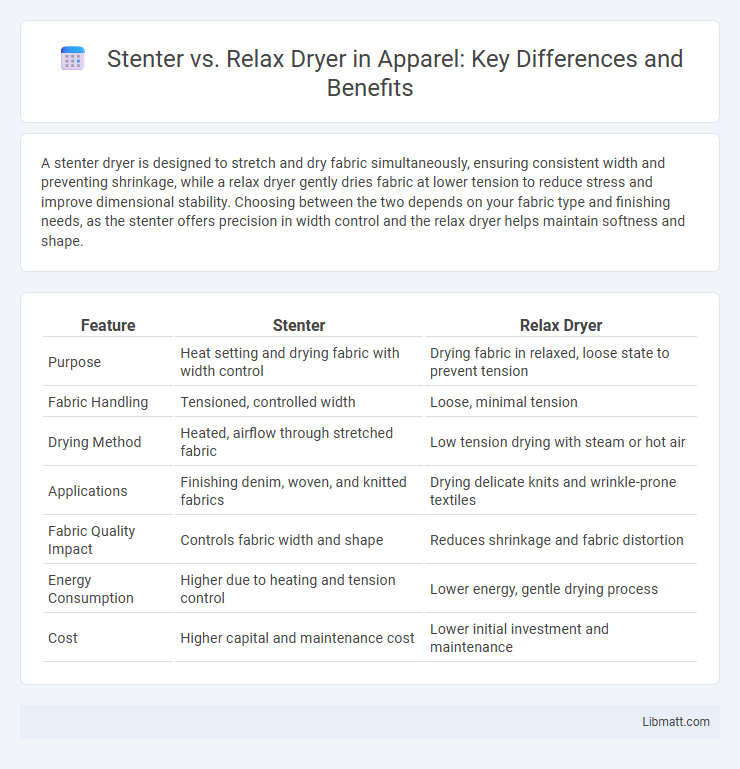

A stenter dryer is designed to stretch and dry fabric simultaneously, ensuring consistent width and preventing shrinkage, while a relax dryer gently dries fabric at lower tension to reduce stress and improve dimensional stability. Choosing between the two depends on your fabric type and finishing needs, as the stenter offers precision in width control and the relax dryer helps maintain softness and shape.

Table of Comparison

| Feature | Stenter | Relax Dryer |

|---|---|---|

| Purpose | Heat setting and drying fabric with width control | Drying fabric in relaxed, loose state to prevent tension |

| Fabric Handling | Tensioned, controlled width | Loose, minimal tension |

| Drying Method | Heated, airflow through stretched fabric | Low tension drying with steam or hot air |

| Applications | Finishing denim, woven, and knitted fabrics | Drying delicate knits and wrinkle-prone textiles |

| Fabric Quality Impact | Controls fabric width and shape | Reduces shrinkage and fabric distortion |

| Energy Consumption | Higher due to heating and tension control | Lower energy, gentle drying process |

| Cost | Higher capital and maintenance cost | Lower initial investment and maintenance |

Introduction to Stenter and Relax Dryer

Stenter machines and relax dryers are essential equipment in textile finishing, designed to dry and stabilize fabric dimensions after processing. Stenter dryers use adjustable pins to hold fabric edges taut for precise width control during drying, enhancing fabric uniformity and quality. Relax dryers allow fabric to shrink naturally in a controlled environment, minimizing tension and reducing distortion, making them ideal for delicate or knit materials.

Key Differences Between Stenter and Relax Dryer

Stenter dryers use adjustable pins to stretch and dry fabric under controlled width, ensuring precise dimensional stability and smooth surface finish. Relax dryers operate by applying steam to relax tension in the fabric, preventing distortion and enhancing elasticity without mechanical stretching. The stenter is ideal for synthetic or blended fabrics requiring exact width control, while the relax dryer suits knit or woolens needing gentle drying to maintain softness and shape.

How Stenter Machines Work

Stenter machines operate by gripping fabric edges on clips or pins to stretch and hold the material at a set width while passing it through heated chambers. This precise tension control ensures uniform drying and dimensional stability, essential for woven and knitted textiles. Your fabric benefits from consistent width retention and enhanced finishing quality compared to relax dryers, which allow fabric to dry without tension.

How Relax Dryers Function

Relax dryers function by gently circulating hot air through fabric that is held under minimal tension, allowing the material to dry evenly without distortion. Unlike stenter dryers that stretch fabric using pins or clips along the edges, relax dryers keep textiles in a relaxed state to prevent dimensional changes and maintain softness. This method is ideal for delicate or stretch-sensitive fabrics, ensuring consistent moisture removal while preserving integrity.

Fabric Types Suitable for Stenter vs Relax Dryer

Stenters are ideal for woven and knitted fabrics requiring precise width control and consistent drying, such as cotton, polyester blends, and delicate synthetics. Relax dryers suit natural fibers like wool and viscose, preventing tension and distortion during drying to preserve fabric softness and texture. You can select the appropriate equipment based on fabric sensitivity and final product quality requirements.

Energy Efficiency Comparison

Stenter dryers typically consume more energy due to their continuous mechanism and high-temperature operation, which is ideal for precise fabric finishing but increases electricity usage. Relax dryers offer superior energy efficiency by employing lower temperatures and controlled fabric tension, reducing heat loss and minimizing energy consumption during textile drying. Selecting between the two depends on balancing energy costs with the specific fabric treatment requirements of polyester, cotton, or blended textiles.

Impact on Fabric Quality

Stenter dryers maintain fabric width and enhance surface smoothness, resulting in crisp, uniform fabric quality ideal for delicate textiles. Relax dryers reduce tension during drying, preventing distortion and improving dimensional stability, which benefits knitwear and stretch fabrics. Your choice between the two directly affects the fabric's hand feel, appearance, and long-term durability.

Cost Analysis: Stenter vs Relax Dryer

Stenter machines generally have higher initial investment and operational costs due to their complex heating and fabric stretching capabilities, leading to increased energy consumption and maintenance expenses. Relax dryers, while often less expensive to purchase and operate, may incur higher cycle times and less precise moisture control, affecting overall production efficiency. Your choice should weigh the stenter's superior fabric quality and throughput against the relax dryer's cost-effectiveness and simpler operation.

Maintenance and Operational Considerations

Stenter machines require regular alignment checks and proactive lubrication to maintain fabric tension and avoid edge damage, while relax dryers demand minimal mechanical adjustments but need consistent temperature monitoring to prevent fabric shrinkage. Cleaning and replacement of clips in stenter frames are critical to avoid fabric snagging, whereas relax dryers focus on drum cleanliness to ensure uniform drying and prevent fabric spots. Operational costs favor relax dryers due to lower energy consumption and simplified maintenance routines, while stenters often incur higher expenses from wear parts and frequent downtime.

Choosing the Right Machine for Your Textile Process

Selecting between a stenter and a relax dryer depends on your textile process requirements, fabric type, and desired finish quality. Stenter machines excel in controlling fabric width, applying heat uniformly, and enabling precise drying and finishing, ideal for synthetic and woven materials. Relax dryers offer gentle tension-free drying suitable for delicate knit fabrics, maintaining dimensional stability and softness, making your choice critical for optimizing fabric performance and production efficiency.

Stenter vs relax dryer Infographic

libmatt.com

libmatt.com