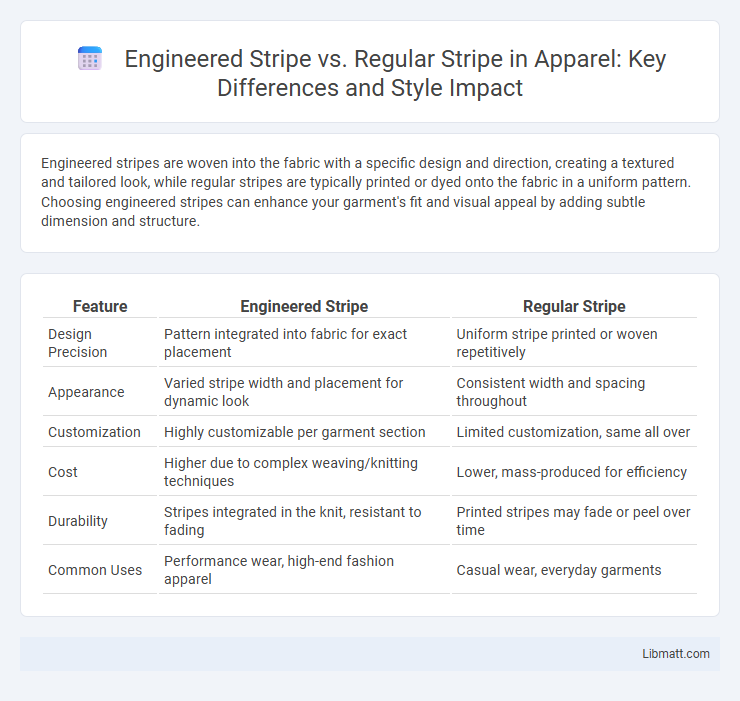

Engineered stripes are woven into the fabric with a specific design and direction, creating a textured and tailored look, while regular stripes are typically printed or dyed onto the fabric in a uniform pattern. Choosing engineered stripes can enhance your garment's fit and visual appeal by adding subtle dimension and structure.

Table of Comparison

| Feature | Engineered Stripe | Regular Stripe |

|---|---|---|

| Design Precision | Pattern integrated into fabric for exact placement | Uniform stripe printed or woven repetitively |

| Appearance | Varied stripe width and placement for dynamic look | Consistent width and spacing throughout |

| Customization | Highly customizable per garment section | Limited customization, same all over |

| Cost | Higher due to complex weaving/knitting techniques | Lower, mass-produced for efficiency |

| Durability | Stripes integrated in the knit, resistant to fading | Printed stripes may fade or peel over time |

| Common Uses | Performance wear, high-end fashion apparel | Casual wear, everyday garments |

Introduction to Engineered Stripe and Regular Stripe

Engineered stripe fabrics feature precisely placed stripe patterns aligned with garment panels, enhancing fit and visual appeal, unlike regular stripe fabrics where stripes are continuous and uniform across the entire textile. Engineered stripes often require advanced manufacturing techniques to ensure patterns match body contours, providing a tailored and modern aesthetic. Regular stripes remain a classic style with consistent, repetitive lines that prioritize simplicity and ease of production.

Defining Engineered Stripe: Key Features

Engineered stripe refers to fabric patterns intentionally designed with varying stripe widths, directions, or textures to enhance visual interest and garment fit, contrasting with regular stripes that maintain consistent, uniform spacing and width. Key features of engineered stripes include precise alignment tailored to garment construction, which optimizes body contours and aesthetic appeal. This technique often uses advanced weaving or knitting methods to integrate multiple stripe patterns seamlessly within a single piece.

Characteristics of Regular Stripe Patterns

Regular stripe patterns exhibit uniform width, spacing, and consistent repetition, resulting in a predictable and symmetrical appearance. These patterns lack variation in texture or alignment, making them easier to manufacture and recognize in textiles, wallpapers, and graphic designs. Regular stripes often convey simplicity and order, commonly used in fashion and interior design to create clean lines and structured aesthetics.

Manufacturing Techniques: Engineered Stripe vs Regular Stripe

Engineered stripe patterns are created using advanced weaving or knitting techniques that vary the thickness, texture, or color placement precisely within the fabric, allowing for intricate designs tailored to specific garment areas. Regular stripes are typically produced through traditional, uniform weaving or printing methods that apply consistent patterns across the entire fabric. Understanding these manufacturing techniques helps you choose fabrics with targeted aesthetics and functionality suited to your clothing needs.

Visual Impact and Design Versatility

Engineered stripes offer precise alignment and consistent patterns that enhance visual impact through sharp, clean lines tailored to specific garment areas, unlike regular stripes which often repeat uniformly and may lack design intricacy. This precision allows designers greater versatility by integrating stripes seamlessly into complex silhouettes and fabric textures, creating dynamic visual effects. Regular stripes tend to limit creativity with their repetitive nature, whereas engineered stripes enable customized aesthetics that elevate fashion innovation.

Durability and Wear Performance Comparison

Engineered stripes are designed with advanced weaving techniques that enhance durability and wear resistance compared to regular stripes, which often use simpler patterns and materials. This results in engineered stripes maintaining their color vibrancy and structural integrity longer under heavy use or frequent washing. Choosing engineered stripe fabrics can significantly improve your garment's lifespan and overall performance in demanding conditions.

Applications in Fashion and Interior Design

Engineered stripes offer precision and intentionality in fashion and interior design, creating visually dynamic patterns that align perfectly with garment contours or furniture shapes, unlike regular stripes which are uniform and repetitive. In fashion, engineered stripes enhance silhouette and structure, making your clothing stand out with tailored, artistic appeal. Interior design benefits from engineered stripes by adding depth and interest to textiles and wallpapers, transforming spaces with bespoke, innovative patterns that elevate overall aesthetics.

Cost Implications and Material Efficiency

Engineered stripes reduce material waste through precise pattern alignment, resulting in lower fabric costs compared to regular stripes, which often generate excess offcuts. The customization and labor involved in engineered stripe production can increase upfront manufacturing expenses but improve overall material utilization by up to 15%. Regular stripes offer simpler, quicker production processes with less initial cost but tend to have higher long-term material inefficiencies and waste.

Consumer Preferences and Market Trends

Engineered stripes offer enhanced durability, precise pattern alignment, and often incorporate sustainable materials, making them increasingly favored by eco-conscious consumers compared to regular stripes. Market trends show a growing demand for engineered stripes in sportswear and casual fashion due to their superior fit and aesthetic appeal, aligning with consumers' preference for both functionality and style. Your choices in apparel can benefit from these advancements, as engineered stripes adapt better to fabric stretch and wear, providing comfort and longevity.

Choosing Between Engineered Stripe and Regular Stripe

Choosing between engineered stripe and regular stripe patterns depends on fabric construction and design precision. Engineered stripes are carefully aligned and often vary in width or direction to enhance garment fit and visual appeal, while regular stripes repeat uniformly across the fabric. Selecting engineered stripes offers tailored aesthetics and structural benefits, ideal for high-quality apparel, whereas regular stripes suit simpler, consistent pattern needs.

Engineered stripe vs regular stripe Infographic

libmatt.com

libmatt.com