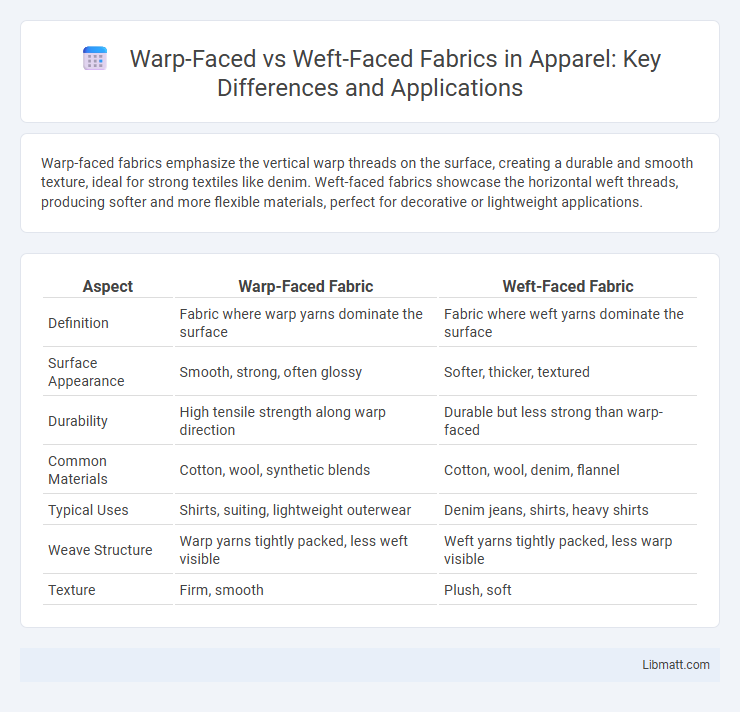

Warp-faced fabrics emphasize the vertical warp threads on the surface, creating a durable and smooth texture, ideal for strong textiles like denim. Weft-faced fabrics showcase the horizontal weft threads, producing softer and more flexible materials, perfect for decorative or lightweight applications.

Table of Comparison

| Aspect | Warp-Faced Fabric | Weft-Faced Fabric |

|---|---|---|

| Definition | Fabric where warp yarns dominate the surface | Fabric where weft yarns dominate the surface |

| Surface Appearance | Smooth, strong, often glossy | Softer, thicker, textured |

| Durability | High tensile strength along warp direction | Durable but less strong than warp-faced |

| Common Materials | Cotton, wool, synthetic blends | Cotton, wool, denim, flannel |

| Typical Uses | Shirts, suiting, lightweight outerwear | Denim jeans, shirts, heavy shirts |

| Weave Structure | Warp yarns tightly packed, less weft visible | Weft yarns tightly packed, less warp visible |

| Texture | Firm, smooth | Plush, soft |

Introduction to Warp-Faced and Weft-Faced Weaving

Warp-faced weaving features yarns running vertically (warp) as the dominant visible element, creating dense, durable fabrics often used in garments and upholstery. Weft-faced weaving emphasizes horizontal yarns (weft), resulting in softer textures and more flexible patterns ideal for decorative textiles like tapestries and blankets. Understanding these two techniques helps you select the right weave to balance strength and aesthetic for your textile projects.

Understanding the Basics: Warp vs. Weft

Warp-faced textiles emphasize yarns running lengthwise (warp) as the dominant visible surface, creating strong, durable fabrics often used in upholstery and outerwear. Weft-faced fabrics highlight crosswise yarns (weft), resulting in softer, more flexible materials commonly found in garments and home textiles. Understanding these fundamental differences helps you select the right fabric based on texture, strength, and appearance for your project.

Key Differences Between Warp-Faced and Weft-Faced Textiles

Warp-faced textiles feature yarns running lengthwise that dominate the fabric's surface, offering greater tensile strength and durability, commonly found in traditional ikat and tartan weavings. Weft-faced textiles emphasize crosswise yarns, producing softer textures ideal for intricate patterns and draping, often used in kilims and tapestries. Your choice between warp-faced and weft-faced fabrics impacts the textile's visual appearance, strength, and application in fashion or home decor.

Common Fabrics Using Warp-Faced Weaving

Warp-faced weaving is characterized by the warp threads being densely packed and visible on the fabric surface, creating strong, durable textiles commonly found in fabrics like satin, gabardine, and serge. These fabrics are favored for their smooth texture, high thread count, and resistance to wear, making them ideal for suits, upholstery, and high-performance apparel. Your choice of warp-faced fabrics ensures longevity and a polished appearance suitable for tailored garments and home decor.

Popular Applications of Weft-Faced Weaving

Weft-faced weaving is commonly used in creating decorative textiles such as tapestries, rugs, and traditional garments where the weft yarns dominate the fabric's surface for vivid color and intricate patterns. This technique is favored in applications requiring detailed imagery and robust texture, often found in cultural textiles from regions like the Andes and the Middle East. Its ability to showcase complex designs makes it popular in both artisanal crafts and modern home decor.

Advantages of Warp-Faced Structures

Warp-faced fabrics offer enhanced durability and strength due to the dominance of warp yarns, which are typically stronger and more tightly twisted. This structure provides superior resistance to abrasion and deformation, making it ideal for applications requiring longevity and robustness. Warp-faced textiles also allow for greater control over texture and appearance, enabling intricate designs with better surface definition.

Benefits of Weft-Faced Weaving Methods

Weft-faced weaving methods offer enhanced design versatility by allowing more visible pattern detail and color variety on the fabric surface, which is ideal for creating intricate textiles. This technique provides superior texture softness and flexibility, making the fabric more comfortable for apparel and home textiles. Your projects benefit from the durability and easy maintenance associated with weft-faced textiles, ensuring long-lasting fabric performance.

Visual Characteristics: Identifying Warp and Weft Dominance

Warp-faced fabrics exhibit a dense, linear texture where the warp threads dominate the surface, creating sharp, vertical patterns and a smooth finish that enhances durability. Weft-faced textiles display broader, horizontal strands with the weft threads prominently visible, resulting in bold horizontal stripes or varied surface textures. Your ability to identify these visual characteristics can assist in selecting the right fabric for specific design and functional purposes.

Techniques and Tools for Warp-Faced vs. Weft-Faced Weaving

Warp-faced weaving employs techniques that emphasize the prominence of warp threads by tightly tensioning the loom and using tools like heddles and rigid heddle looms to maintain consistent warp alignment. Weft-faced weaving prioritizes the weft threads, utilizing shuttle or bobbin mechanisms to densely pack weft yarns, often requiring beaters or combs to create a smooth surface. Both styles depend on precise tension control and weave structure manipulation, but warp-faced techniques focus on warp thread visibility, while weft-faced techniques leverage weft thread density for design and texture.

Choosing the Right Weaving Method for Your Project

Warp-faced weaving emphasizes the vertical warp threads, creating durable, tightly woven fabrics ideal for structured garments or intricate patterns. Weft-faced weaving highlights the horizontal weft threads, offering softer, more flexible textiles suitable for drapery and decorative projects. Choosing the right weaving method depends on your project's desired texture, strength, and appearance to ensure optimal fabric performance.

Warp-faced vs weft-faced Infographic

libmatt.com

libmatt.com