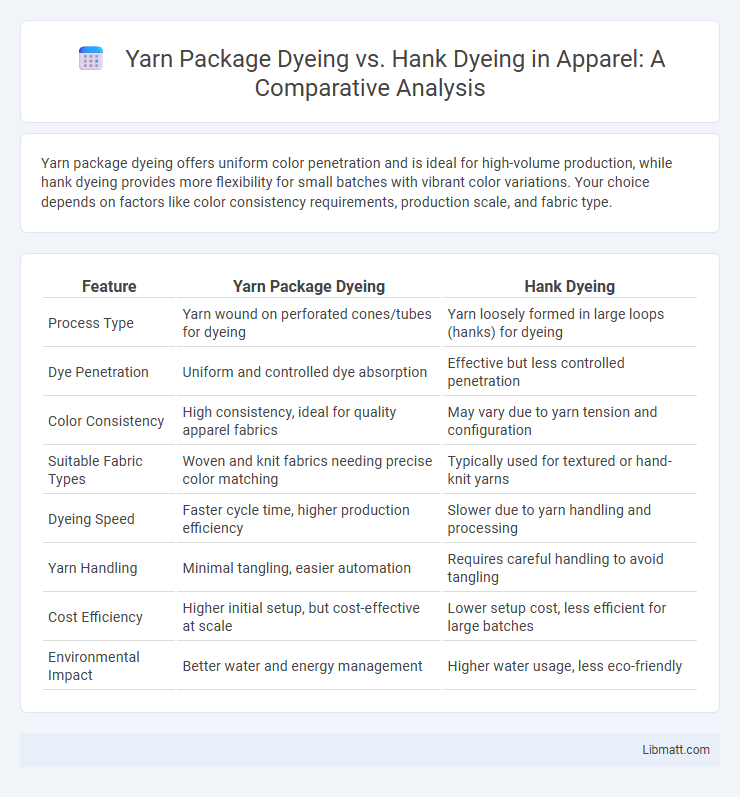

Yarn package dyeing offers uniform color penetration and is ideal for high-volume production, while hank dyeing provides more flexibility for small batches with vibrant color variations. Your choice depends on factors like color consistency requirements, production scale, and fabric type.

Table of Comparison

| Feature | Yarn Package Dyeing | Hank Dyeing |

|---|---|---|

| Process Type | Yarn wound on perforated cones/tubes for dyeing | Yarn loosely formed in large loops (hanks) for dyeing |

| Dye Penetration | Uniform and controlled dye absorption | Effective but less controlled penetration |

| Color Consistency | High consistency, ideal for quality apparel fabrics | May vary due to yarn tension and configuration |

| Suitable Fabric Types | Woven and knit fabrics needing precise color matching | Typically used for textured or hand-knit yarns |

| Dyeing Speed | Faster cycle time, higher production efficiency | Slower due to yarn handling and processing |

| Yarn Handling | Minimal tangling, easier automation | Requires careful handling to avoid tangling |

| Cost Efficiency | Higher initial setup, but cost-effective at scale | Lower setup cost, less efficient for large batches |

| Environmental Impact | Better water and energy management | Higher water usage, less eco-friendly |

Introduction to Yarn Package Dyeing and Hank Dyeing

Yarn Package Dyeing involves dyeing yarns wound on perforated spools, allowing uniform penetration and rapid processing ideal for blending and mass production in textile manufacturing. Hank Dyeing uses loosely coiled yarns, offering superior dye uniformity and depth, making it suitable for high-quality, handwoven or artisanal fabrics. Each method optimizes dye absorption based on yarn arrangement, impacting colorfastness and fabric texture in the final production stages.

Overview of Yarn Dyeing Techniques

Yarn package dyeing involves dyeing yarns wound on perforated cones, enabling efficient and uniform penetration of dye liquor through forced liquor circulation. Hank dyeing, by contrast, processes yarns loosely wound in skeins, allowing thorough dye absorption but requiring careful handling to prevent tangling. Both methods are essential in textile manufacturing, with package dyeing favored for speed and automation, while hank dyeing offers superior dye depth and quality for specialty yarns.

Process of Yarn Package Dyeing

Yarn Package Dyeing involves winding yarn onto perforated spools that allow dye to penetrate evenly during the dyeing process, ensuring uniform color throughout the yarn. This method uses high-pressure and temperature conditions to facilitate deep dye absorption, resulting in enhanced colorfastness and vibrancy. Your production benefits from improved efficiency and consistency compared to traditional hank dyeing.

Process of Hank Dyeing

The process of hank dyeing involves immersing yarns loosely wound into large coils called hanks into a dye bath, allowing the dye to penetrate evenly through the fibers. This method ensures excellent color absorption and uniformity, making it ideal for high-quality, richly dyed yarns. If you seek vibrant and consistent coloration, hank dyeing offers superior results compared to other dyeing techniques.

Key Differences Between Package and Hank Dyeing

Package dyeing involves dyeing yarn wound on perforated tubes, allowing rapid and uniform color penetration, making it ideal for synthetic and blended fibers. Hank dyeing processes yarn loosely coiled into hanks, providing excellent dye uniformity and suitability for delicate fibers like wool and silk, but requiring more water and time. Your choice depends on fiber type, production scale, and desired dye quality, as package dyeing offers efficiency while hank dyeing ensures superior color consistency for specialty yarns.

Color Consistency and Quality Comparison

Yarn package dyeing offers superior color consistency due to its controlled dye application and uniform flow of dye liquor through compact yarn packages, reducing unevenness and color variations commonly seen in hank dyeing. Hank dyeing, involving loose skeins, often results in less uniform dye penetration, increasing the risk of color streaks and patchiness, which can affect fabric quality. Consequently, package dyeing ensures higher-quality, reproducible colors favored in industrial textile production for achieving precise shade matching and fastness properties.

Efficiency and Production Speed

Yarn package dyeing offers greater efficiency and faster production speed compared to hank dyeing due to its continuous process and automated machinery, enabling high-volume output with consistent color quality. Hank dyeing requires more manual handling and longer processing times, limiting its suitability for large-scale manufacturing where rapid turnaround is essential. Manufacturers prioritize yarn package dyeing to optimize workflow and reduce dyeing cycle times in commercial textile production.

Environmental Impact and Resource Usage

Yarn package dyeing consumes higher water and energy due to its rapid dyeing process in pressurized machines, resulting in increased effluent production and chemical usage compared to hank dyeing. Hank dyeing, involving yarns loosely wound into skeins, allows for better penetration and dye uniformity with generally lower water and energy consumption, reducing environmental burden. The choice significantly impacts sustainability, with hank dyeing favored for eco-friendly textile production due to minimized resource usage and reduced pollutant discharge.

Cost Factors in Package vs Hank Dyeing

Yarn package dyeing generally incurs higher costs due to increased machinery expenses, longer processing times, and greater energy consumption compared to hank dyeing. Hank dyeing is often more cost-effective for smaller batches as it uses less yarn tension and allows better dye penetration, reducing the need for reprocessing. Your choice between package and hank dyeing should consider production volume and fabric requirements to optimize cost efficiency.

Selecting the Best Yarn Dyeing Method for Your Needs

Selecting the best yarn dyeing method for your needs depends on factors like colorfastness, fabric type, and production scale. Yarn package dyeing offers uniform penetration and is ideal for synthetic fibers and large batches, while hank dyeing provides superior dye absorption and is preferred for delicate, natural fibers and small runs. Understanding these differences ensures optimal color quality and material performance tailored to your project.

Yarn Package Dyeing vs Hank Dyeing Infographic

libmatt.com

libmatt.com