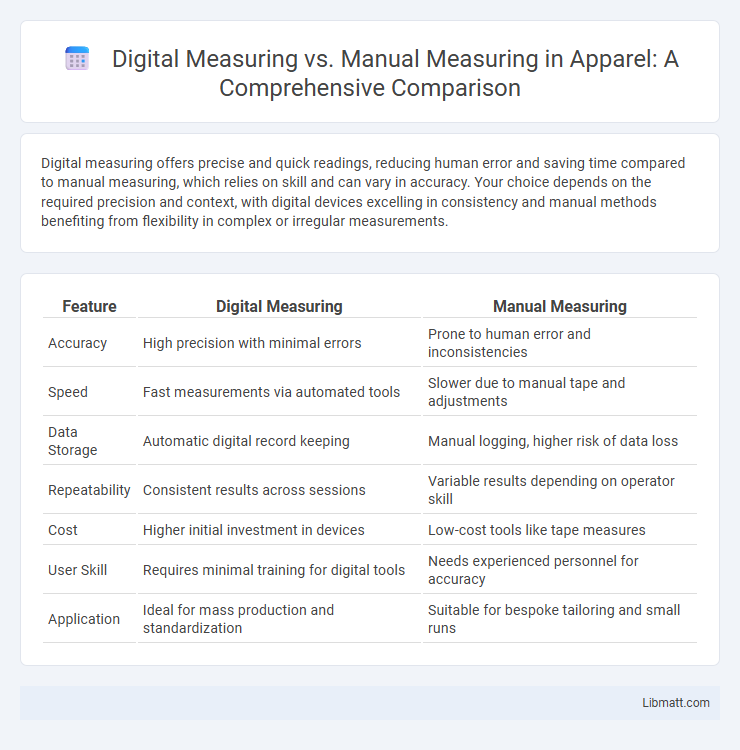

Digital measuring offers precise and quick readings, reducing human error and saving time compared to manual measuring, which relies on skill and can vary in accuracy. Your choice depends on the required precision and context, with digital devices excelling in consistency and manual methods benefiting from flexibility in complex or irregular measurements.

Table of Comparison

| Feature | Digital Measuring | Manual Measuring |

|---|---|---|

| Accuracy | High precision with minimal errors | Prone to human error and inconsistencies |

| Speed | Fast measurements via automated tools | Slower due to manual tape and adjustments |

| Data Storage | Automatic digital record keeping | Manual logging, higher risk of data loss |

| Repeatability | Consistent results across sessions | Variable results depending on operator skill |

| Cost | Higher initial investment in devices | Low-cost tools like tape measures |

| User Skill | Requires minimal training for digital tools | Needs experienced personnel for accuracy |

| Application | Ideal for mass production and standardization | Suitable for bespoke tailoring and small runs |

Introduction to Digital and Manual Measuring

Digital measuring employs advanced electronic tools such as laser distance meters and digital calipers, offering high precision and faster data acquisition compared to manual methods. Manual measuring relies on traditional instruments like tape measures and rulers, requiring human skill and experience, which can introduce variability and longer measuring times. The choice between digital and manual measuring impacts accuracy, efficiency, and data management in various industrial and construction applications.

Key Differences Between Digital and Manual Measurement

Digital measuring offers precise, quick readings with data consistently displayed on electronic screens, reducing human error common in manual measurement methods. Manual measuring relies on physical tools like rulers or tape measures, requiring interpretation and often causing variations due to human factors. Your choice between digital and manual measurement affects accuracy, speed, and ease of data recording depending on the task complexity and required precision.

Accuracy and Precision: Digital vs. Manual

Digital measuring tools provide superior accuracy and precision compared to manual methods due to advanced sensors and electronic calibration, reducing human error significantly. Digital devices offer consistent repeatability with minimal variance, while manual measuring relies heavily on user skill, leading to potential discrepancies. The integration of digital readouts ensures exact measurements and enhances reliability in critical applications such as engineering and quality control.

Speed and Efficiency in Measurement Methods

Digital measuring tools deliver faster and more efficient measurement results compared to manual methods, reducing human error and saving valuable time. Your workflow improves significantly with digital devices that provide instant readings and automated data recording. This enhanced speed and accuracy translate into increased productivity and reliable measurement outcomes in various applications.

Ease of Use: User Experience Compared

Digital measuring tools offer enhanced ease of use by providing instant, accurate readings with minimal effort, reducing the chance of human error common in manual measuring. Your experience improves significantly as digital devices often include features like backlit displays, memory storage, and automatic calibration, making measurements faster and more reliable. Manual measuring requires more skill and patience, often slowing down workflows and increasing the risk of inconsistent results.

Data Recording and Analysis Capabilities

Digital measuring devices provide precise data recording with automated storage options, enabling seamless export to software for advanced statistical analysis and trend monitoring. Manual measuring relies on handwritten notes that can be prone to human error, making data aggregation and comprehensive analysis more time-consuming and less reliable. The integration of digital tools enhances accuracy, efficiency, and the ability to track long-term performance through sophisticated data visualization.

Cost Considerations: Initial Investment and Maintenance

Digital measuring tools often require a higher initial investment compared to manual measuring devices due to advanced technology and precision components. Maintenance costs for digital devices may include frequent calibration, software updates, and potential repairs, which can add up over time. Your choice should weigh the upfront expenses against long-term accuracy and efficiency benefits.

Versatility and Application Range

Digital measuring tools offer enhanced versatility and a broader application range, capable of accurately measuring complex shapes, varying units, and dynamic environments with ease. Manual measuring tools, while reliable for straightforward tasks, often lack adaptability for intricate measurements and diverse materials. The precision and programmable features of digital devices make them ideal for industries requiring high accuracy across multiple measurement types.

Common Errors: Human vs. Machine

Manual measuring often encounters common errors such as parallax, inconsistent pressure, and misreading scales, leading to inaccuracies. Digital measuring tools minimize human error by providing precise, consistent readings with built-in error correction features. Despite this, digital devices may face calibration drift or sensor malfunctions, but overall they deliver higher accuracy and repeatability compared to manual methods.

Choosing the Right Measuring Method for Your Needs

Digital measuring tools offer increased accuracy, faster results, and easy data storage, making them ideal for precision-dependent tasks and large-scale projects. Manual measuring methods provide flexibility, cost-effectiveness, and reliability in environments where technology may fail or simple measurements suffice. Consider your project's accuracy requirements, budget, and working conditions to choose the right measuring method for your needs.

digital measuring vs manual measuring Infographic

libmatt.com

libmatt.com