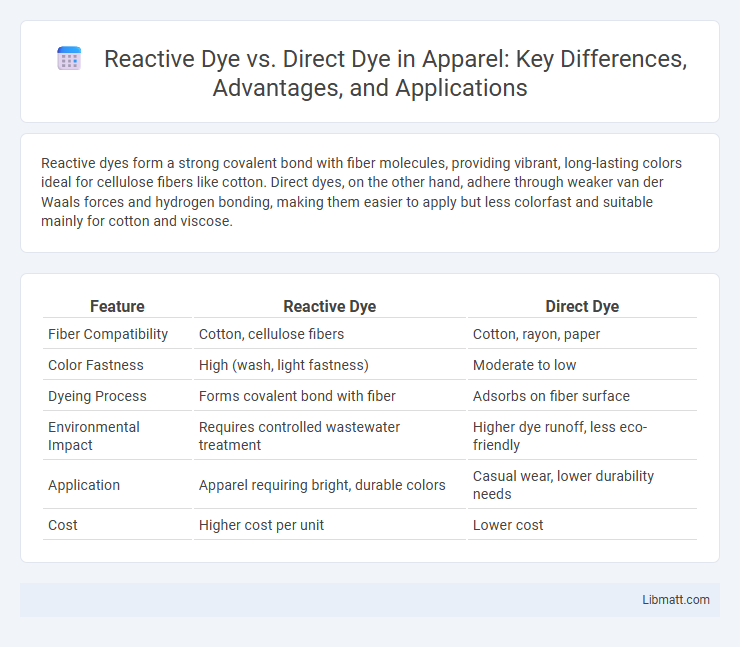

Reactive dyes form a strong covalent bond with fiber molecules, providing vibrant, long-lasting colors ideal for cellulose fibers like cotton. Direct dyes, on the other hand, adhere through weaker van der Waals forces and hydrogen bonding, making them easier to apply but less colorfast and suitable mainly for cotton and viscose.

Table of Comparison

| Feature | Reactive Dye | Direct Dye |

|---|---|---|

| Fiber Compatibility | Cotton, cellulose fibers | Cotton, rayon, paper |

| Color Fastness | High (wash, light fastness) | Moderate to low |

| Dyeing Process | Forms covalent bond with fiber | Adsorbs on fiber surface |

| Environmental Impact | Requires controlled wastewater treatment | Higher dye runoff, less eco-friendly |

| Application | Apparel requiring bright, durable colors | Casual wear, lower durability needs |

| Cost | Higher cost per unit | Lower cost |

Introduction to Dyeing: Reactive vs Direct Dyes

Reactive dyes form covalent bonds with cellulose fibers, offering superior wash fastness and vibrant colors, making them ideal for cotton and other plant-based textiles. Direct dyes adhere to fibers through weaker hydrogen bonds, often requiring mordants for improved durability, and are typically used for simple, low-cost dyeing processes. Both dye types differ significantly in chemical structure and application methods, impacting their suitability for various fabric types and end-use requirements.

Chemical Structure and Composition

Reactive dyes feature complex chromophores containing reactive groups such as vinyl sulfone or dichlorotriazine, enabling covalent bonding with cellulose fibers, which enhances color fastness. Direct dyes consist of azo or anthraquinone chromophores with sulfonic acid groups that facilitate water solubility and ionically bond with fibers through hydrogen bonding and Van der Waals forces. The chemical composition of reactive dyes allows permanent fixation through covalent linkages, whereas direct dyes rely on physical adsorption and weaker intermolecular forces for attachment.

Mechanism of Dye-Fiber Bonding

Reactive dyes form covalent bonds with cellulose fibers through a chemical reaction between the dye's reactive groups and the hydroxyl groups on the fiber, resulting in strong, permanent fixation. Direct dyes rely primarily on van der Waals forces and hydrogen bonding to adhere to cellulosic fibers, leading to weaker attachment and lower wash fastness compared to reactive dyes. The covalent bonding mechanism of reactive dyes enhances color durability and resistance to fading during laundering.

Application Methods and Processes

Reactive dyes are primarily applied using a cold or warm water fixation process involving fiber-reactive groups that form covalent bonds with cellulose fibers, ensuring vibrant, long-lasting colors on cotton and other cellulosic materials. Direct dyes are typically applied through a simple exhaustion process where the dye molecules are absorbed onto the fiber surface without chemical bonding, making them suitable for bulk dyeing of cotton with moderate wash fastness. The application of reactive dyes requires precise control of pH and temperature to promote chemical reaction, while direct dyes demand higher dye concentrations and salt addition to achieve uniform coloration during the dyeing process.

Color Fastness Comparison

Reactive dyes exhibit superior color fastness compared to direct dyes, particularly in terms of wash and light fastness, due to their chemical bonding with fiber molecules. Direct dyes, while easier to apply, tend to have lower resistance to fading and washing, making them less durable for long-term use. Your choice between the two should consider the desired durability and fabric type to ensure optimal color retention.

Color Vibrancy and Shade Range

Reactive dyes produce more vibrant colors and a broader shade range compared to direct dyes due to their chemical bonding with cellulose fibers, resulting in superior color fastness and brightness. Direct dyes typically offer less intense shades with limited vibrancy because they adhere to fabric surfaces through weaker physical forces, leading to more muted colors. Fabrics treated with reactive dyes exhibit enhanced color depth and durability, making them ideal for applications demanding rich and lasting hues.

Environmental Impact and Sustainability

Reactive dyes form strong covalent bonds with fibers, resulting in higher fixation rates and less dye runoff, which reduces environmental pollution compared to direct dyes that typically adhere via weaker interactions and generate more wastewater contaminants. You can minimize ecological footprint by choosing reactive dyes, as they require lower temperature and less water in the dyeing process, supporting sustainable textile manufacturing practices. Effluent treatment for reactive dyes tends to be simpler and less energy-intensive, promoting better water conservation and reduced chemical load in industrial effluents.

Cost Efficiency and Economic Considerations

Reactive dyes often provide higher cost efficiency by creating stronger covalent bonds with fibers, which results in longer-lasting, vibrant colors and reduced dye wastage during washing. Direct dyes tend to have lower initial costs but may require more dye and frequent reapplication, increasing overall expenses. Your choice between reactive and direct dyes should weigh the initial investment against long-term durability and maintenance costs to optimize economic outcomes.

Suitability for Different Fiber Types

Reactive dyes form strong covalent bonds with cellulose fibers such as cotton, making them highly suitable for natural fibers, while direct dyes primarily adhere through weaker van der Waals forces and hydrogen bonding, ideal for cotton but less effective on protein fibers like wool and silk. Your choice depends on the fiber type: reactive dyes provide vibrant, long-lasting colors on cellulosic materials, whereas direct dyes offer easier application but lower wash fastness suited for cellulose fibers. For synthetic fibers, neither dye performs optimally without modification or auxiliary agents.

Industrial Uses and End-Product Performance

Reactive dyes are widely preferred in industrial textile manufacturing for dyeing cellulose fibers like cotton, offering excellent colorfastness and vibrant hues ideal for clothing and home textiles. Direct dyes, often used in paper and leather industries, provide economical and straightforward application but generally yield lower wash and light fastness compared to reactive dyes. Your choice between these dyes impacts the durability, color intensity, and environmental footprint of the final product.

Reactive dye vs direct dye Infographic

libmatt.com

libmatt.com