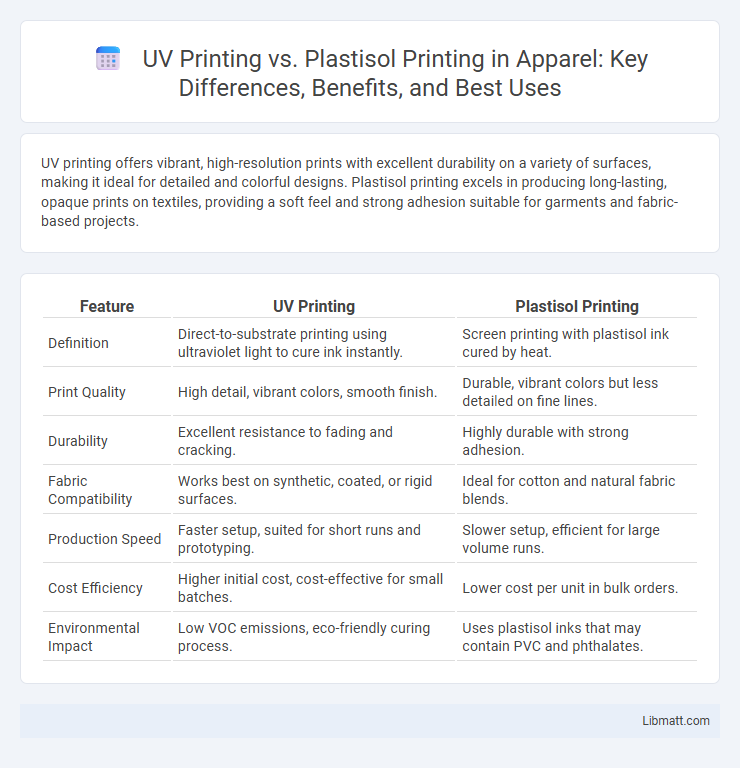

UV printing offers vibrant, high-resolution prints with excellent durability on a variety of surfaces, making it ideal for detailed and colorful designs. Plastisol printing excels in producing long-lasting, opaque prints on textiles, providing a soft feel and strong adhesion suitable for garments and fabric-based projects.

Table of Comparison

| Feature | UV Printing | Plastisol Printing |

|---|---|---|

| Definition | Direct-to-substrate printing using ultraviolet light to cure ink instantly. | Screen printing with plastisol ink cured by heat. |

| Print Quality | High detail, vibrant colors, smooth finish. | Durable, vibrant colors but less detailed on fine lines. |

| Durability | Excellent resistance to fading and cracking. | Highly durable with strong adhesion. |

| Fabric Compatibility | Works best on synthetic, coated, or rigid surfaces. | Ideal for cotton and natural fabric blends. |

| Production Speed | Faster setup, suited for short runs and prototyping. | Slower setup, efficient for large volume runs. |

| Cost Efficiency | Higher initial cost, cost-effective for small batches. | Lower cost per unit in bulk orders. |

| Environmental Impact | Low VOC emissions, eco-friendly curing process. | Uses plastisol inks that may contain PVC and phthalates. |

Introduction to UV Printing and Plastisol Printing

UV printing uses ultraviolet light to cure ink instantly on various surfaces, offering vibrant colors and durability, ideal for detailed graphics on non-porous materials. Plastisol printing involves applying heat-cured ink to fabric, creating a flexible, long-lasting design commonly used in textile and apparel industries. Understanding these distinct methods helps you choose the best printing technique for your project's material and durability needs.

Core Differences Between UV and Plastisol Printing

UV printing uses ultraviolet light to cure ink directly onto surfaces, resulting in fast drying times and vibrant, durable prints ideal for rigid materials. Plastisol printing relies on heat to cure ink made from PVC particles suspended in a plasticizer, providing excellent opacity and flexibility suited for textile applications. Core differences include curing technology--UV's instant drying versus Plastisol's heat-based curing--compatibility with substrates, and the level of detail and texture achievable in the final print.

How UV Printing Works

UV printing uses ultraviolet light to cure or dry the ink instantly as it is printed onto a surface, creating a durable, high-resolution image. The process involves a digital printer that applies liquid ink onto the substrate, followed by exposure to UV light that solidifies the ink through photopolymerization. This method enables vibrant colors and fine details on various materials such as plastic, metal, and glass, distinguishing it from plastisol printing, which relies on heat to cure ink.

How Plastisol Printing Works

Plastisol printing uses a PVC-based ink that sits on the fabric's surface, offering vibrant colors and durability. The ink requires heat curing, typically around 320degF, to solidify and bond with the garment fibers. This method supports detailed designs and works well on various textiles, especially cotton and polyester blends.

Print Quality Comparison

UV printing delivers sharp, vibrant colors with high detail resolution due to its ability to cure ink instantly on various surfaces, making it ideal for intricate designs and photorealistic images. Plastisol printing provides rich, opaque colors with excellent durability, especially on textiles, ensuring long-lasting prints resistant to fading and cracking. Your choice between UV and Plastisol printing should consider the substrate and desired print longevity alongside the quality characteristics each method excels in.

Durability and Longevity

UV printing offers superior durability with its ability to resist fading, cracking, and peeling due to the UV light curing process that hardens the ink instantly on surfaces. Plastisol printing provides strong longevity on fabric, maintaining vibrant colors through multiple washes, but is more prone to cracking and fading over extended use compared to UV prints. For applications requiring long-term exposure to harsh environmental conditions, UV printing generally outperforms plastisol printing in maintaining print integrity.

Suitability for Various Materials

UV printing excels in versatility, effectively adhering to a wide range of materials including plastics, glass, metal, and wood due to its UV-curable ink technology. Plastisol printing is best suited for textiles, especially cotton and polyester blends, offering vibrant colors and durability on fabrics but limited application on non-porous surfaces. The choice between UV and plastisol printing largely depends on the substrate, with UV providing better adaptability across diverse materials and plastisol dominating in garment printing.

Eco-Friendliness and Safety

UV printing uses ultraviolet light to cure ink instantly, producing minimal volatile organic compounds (VOCs) and reducing environmental impact, making it more eco-friendly than traditional Plastisol printing, which relies on PVC-based inks that release harmful phthalates. Plastisol inks require heat curing, posing safety risks through toxic fumes and exposure to heavy metals, whereas UV printing is safer for your health with lower chemical emissions. Choosing UV printing enhances sustainability and workplace safety by minimizing hazardous waste and toxic exposure.

Cost Considerations

UV printing typically involves higher initial equipment and ink costs but offers lower long-term expenses due to minimal setup and faster production times. Plastisol printing requires less expensive machinery but incurs higher costs per color and setup, especially for small runs, making it less cost-effective for short print jobs. Your choice depends on the volume and complexity of your projects, with UV printing being more economical for diverse, low-quantity prints and plastisol favoring large, uniform batches.

Choosing the Right Printing Method for Your Needs

UV printing offers vibrant, durable prints with quick drying times and is ideal for detailed designs on various substrates like plastic, metal, and wood. Plastisol printing excels in producing soft, flexible prints on textile materials, especially for bulk orders requiring consistent color and opacity. Your choice depends on the surface material, design complexity, and production volume to ensure the best printing method suits your project's specific requirements.

UV Printing vs Plastisol Printing Infographic

libmatt.com

libmatt.com