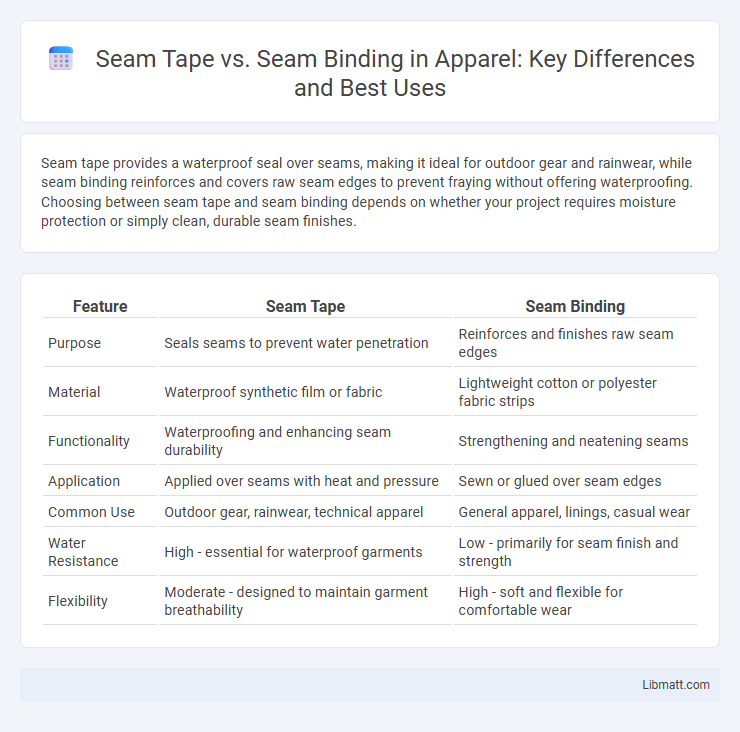

Seam tape provides a waterproof seal over seams, making it ideal for outdoor gear and rainwear, while seam binding reinforces and covers raw seam edges to prevent fraying without offering waterproofing. Choosing between seam tape and seam binding depends on whether your project requires moisture protection or simply clean, durable seam finishes.

Table of Comparison

| Feature | Seam Tape | Seam Binding |

|---|---|---|

| Purpose | Seals seams to prevent water penetration | Reinforces and finishes raw seam edges |

| Material | Waterproof synthetic film or fabric | Lightweight cotton or polyester fabric strips |

| Functionality | Waterproofing and enhancing seam durability | Strengthening and neatening seams |

| Application | Applied over seams with heat and pressure | Sewn or glued over seam edges |

| Common Use | Outdoor gear, rainwear, technical apparel | General apparel, linings, casual wear |

| Water Resistance | High - essential for waterproof garments | Low - primarily for seam finish and strength |

| Flexibility | Moderate - designed to maintain garment breathability | High - soft and flexible for comfortable wear |

Understanding Seam Tape and Seam Binding

Seam tape and seam binding serve essential roles in garment construction and fabric finishing. Seam tape is a narrow strip of fabric with adhesive or fusible properties used to reinforce or seal seams, especially in waterproof or outdoor gear, ensuring durability and preventing water penetration. Seam binding, often made from bias-cut fabric, encases raw edges to prevent fraying and adds a clean, professional finish to your sewing projects.

Key Differences Between Seam Tape and Seam Binding

Seam tape and seam binding differ primarily in material and application: seam tape is typically adhesive and designed to create waterproof or airtight seals on fabric seams, making it essential for outdoor gear and rainwear. Seam binding is a non-adhesive fabric strip used to finish raw edges, preventing fraying and enhancing durability in garments and upholstery. Your choice depends on the need for sealing seams versus simply reinforcing and finishing edges.

Material Composition: Seam Tape vs Seam Binding

Seam tape is typically made from synthetic materials such as polyester or nylon laminated with a waterproof film for enhanced moisture resistance, making it ideal for sealing seams in waterproof garments. Seam binding, on the other hand, is usually crafted from woven cotton, polyester, or a cotton-polyester blend, providing a durable yet flexible edge finish primarily for reinforcing and preventing fraying on fabric seams. The material composition of seam tape offers superior waterproofing properties, whereas seam binding focuses on durability and flexibility for standard seam reinforcement.

Common Applications in Sewing and Crafting

Seam tape is commonly used in sewing to reinforce and waterproof seams in outdoor gear and sportswear, providing a durable barrier against moisture. Seam binding, on the other hand, is favored for finishing raw edges in quilting, garment construction, and home decor projects, offering a neat, decorative edge that prevents fraying. Understanding these applications helps you select the appropriate material for durability or aesthetic finish in your sewing or crafting projects.

Durability and Longevity Comparison

Seam tape provides enhanced durability by creating a waterproof and airtight seal, making it ideal for applications requiring strong, long-lasting protection against moisture and wear. Seam binding, while effective for reinforcing raw edges and preventing fraying, generally offers less resistance to external elements and tends to wear out faster under heavy use. For projects demanding maximum longevity, seam tape outperforms seam binding in maintaining fabric integrity over time.

Ease of Application for Beginners

Seam tape offers greater ease of application for beginners due to its adhesive backing that simplifies securing fabric edges without sewing. Seam binding requires more skill and time as it involves folding and stitching fabric strips neatly along the seams. Your choice depends on whether you prefer a quick, no-sew solution or a more durable finish with basic sewing skills.

Cost Analysis: Affordability of Each Method

Seam tape generally incurs higher costs due to its adhesive backing and specialized materials, making it ideal for waterproof or high-performance applications. Seam binding, often made from cotton or polyester fabric strips, is more budget-friendly and suited for reinforcing or finishing seams in everyday garments. When prioritizing affordability, seam binding offers a cost-effective solution for standard sewing needs, while seam tape justifies its expense with durability and enhanced protection.

Visual Impact on Finished Projects

Seam tape creates a smooth, flat finish that enhances the sleek and professional appearance of garments or quilts, minimizing bulk at the seams for a cleaner look. Seam binding adds a decorative edge that can introduce texture and color contrast, making seams stand out as intentional design elements. Your choice between seam tape and seam binding will directly influence the visual impact by either emphasizing seamless sleekness or bold, decorative outlines on the finished project.

Best Practices for Seam Reinforcement

Seam tape offers superior waterproofing and durability for seam reinforcement in outdoor gear and technical apparel, making it ideal for preventing water penetration and enhancing fabric longevity. Seam binding provides a lightweight and flexible method to cover raw edges, reducing fraying and increasing seam strength without compromising garment flexibility. For optimal seam reinforcement, select seam tape when waterproof integrity and heavy-duty protection are critical, while seam binding suits applications demanding breathability and minimal bulk.

Choosing the Right Option for Your Project

Seam tape provides a strong, waterproof seal ideal for outdoor gear and rainwear, while seam binding offers a decorative finish that reinforces seams without bulk, perfect for garments and upholstery. Your choice depends on the project's purpose, whether you need durability and water resistance or a neat, flexible edge finish. For projects requiring both protection and appearance, consider the material type and seam stress to select the appropriate option.

Seam tape vs seam binding Infographic

libmatt.com

libmatt.com