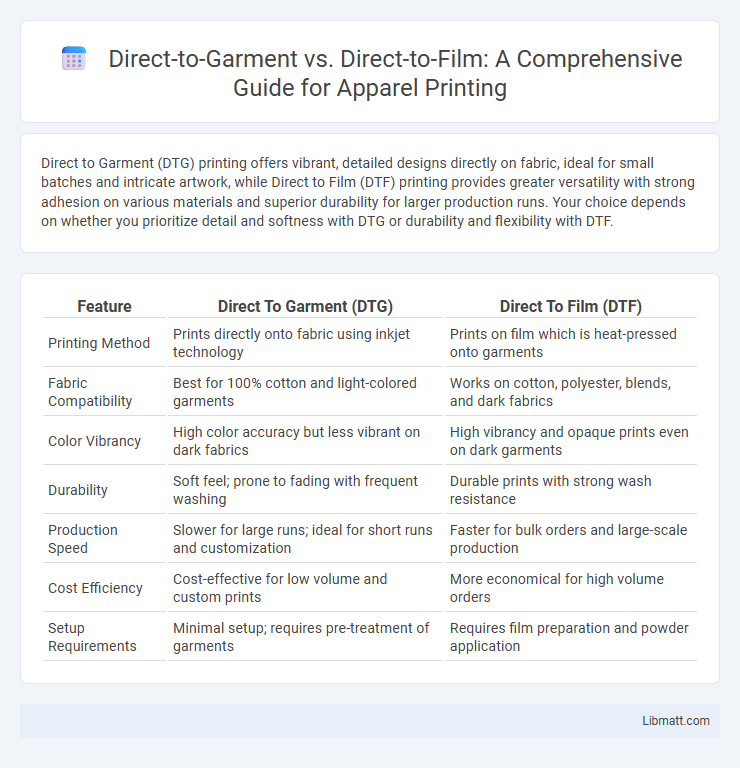

Direct to Garment (DTG) printing offers vibrant, detailed designs directly on fabric, ideal for small batches and intricate artwork, while Direct to Film (DTF) printing provides greater versatility with strong adhesion on various materials and superior durability for larger production runs. Your choice depends on whether you prioritize detail and softness with DTG or durability and flexibility with DTF.

Table of Comparison

| Feature | Direct To Garment (DTG) | Direct To Film (DTF) |

|---|---|---|

| Printing Method | Prints directly onto fabric using inkjet technology | Prints on film which is heat-pressed onto garments |

| Fabric Compatibility | Best for 100% cotton and light-colored garments | Works on cotton, polyester, blends, and dark fabrics |

| Color Vibrancy | High color accuracy but less vibrant on dark fabrics | High vibrancy and opaque prints even on dark garments |

| Durability | Soft feel; prone to fading with frequent washing | Durable prints with strong wash resistance |

| Production Speed | Slower for large runs; ideal for short runs and customization | Faster for bulk orders and large-scale production |

| Cost Efficiency | Cost-effective for low volume and custom prints | More economical for high volume orders |

| Setup Requirements | Minimal setup; requires pre-treatment of garments | Requires film preparation and powder application |

Introduction to DTG and DTF Printing

Direct To Garment (DTG) printing uses specialized inkjet technology to apply vibrant, full-color designs directly onto fabric, ideal for detailed artwork and small print runs. Direct To Film (DTF) printing involves transferring designs from a film onto garments, offering excellent adhesion and versatility across various fabric types. Your choice between DTG and DTF depends on factors like fabric compatibility, design complexity, and production volume.

How Direct To Garment (DTG) Printing Works

Direct To Garment (DTG) printing works by using advanced inkjet technology to apply water-based textile inks directly onto the fabric, allowing for high-resolution, full-color designs with intricate details. Unlike Direct To Film (DTF), which prints on a transferable film before heating it onto the garment, DTG presses the ink straight into the fibers, resulting in a softer feel and better breathability. Understanding how DTG works can help you choose the best printing method for vibrant, durable prints on cotton or cotton-blend fabrics.

How Direct To Film (DTF) Printing Works

Direct To Film (DTF) printing involves printing designs onto a special PET film using water-based inks, which are then coated with adhesive powder and heat-cured to prepare for transfer. The film with the cured adhesive is placed onto the garment and heat-pressed, allowing the design to bond firmly to various fabric types. This method offers vibrant colors, excellent wash durability, and flexibility on different materials, making it a versatile alternative to Direct To Garment (DTG) printing.

Equipment and Setup Requirements

Direct To Garment (DTG) printing requires specialized inkjet printers designed to apply ink directly onto fabric, demanding a controlled environment for optimal ink adhesion and drying. Direct To Film (DTF) involves printing designs onto a special film using a standard pigment ink printer, followed by powder application and heat pressing equipment to transfer the image onto the garment. Your choice between DTG and DTF will depend on the availability of precise printing machinery and post-printing setup like heat presses.

Print Quality Comparison

Direct To Garment (DTG) offers vibrant, high-resolution prints ideal for intricate designs and photographic images, ensuring your apparel showcases fine details and smooth color gradients. Direct To Film (DTF) produces durable prints with excellent opacity on dark fabrics, but may lack the same level of color depth and detail as DTG. When prioritizing print quality, DTG typically delivers superior image sharpness and softer hand feel, enhancing the overall garment appearance.

Fabric Compatibility and Versatility

Direct To Garment (DTG) printing excels on 100% cotton fabrics, providing vibrant colors and soft handfeel, but it struggles with polyester and blended textiles. Direct To Film (DTF) printing offers greater fabric compatibility, working effectively on cotton, polyester, blends, and even nylon, making it a versatile choice for a wide range of garments. The versatility of DTF extends to various fabric types without compromising print quality, unlike DTG which often requires pretreatment and fabric-specific adjustments.

Production Speed and Efficiency

Direct To Film (DTF) offers faster production speeds compared to Direct To Garment (DTG) due to its simplified printing process and ability to produce transfers in bulk ahead of time. DTF's efficiency is enhanced by its compatibility with various fabrics and lower maintenance requirements, reducing downtime and increasing output. Your choice between these methods can significantly impact turnaround times and cost-effectiveness in high-volume print environments.

Cost Analysis: DTG vs DTF

Direct To Garment (DTG) printing generally involves higher upfront costs due to expensive printers and frequent ink replenishment, whereas Direct To Film (DTF) offers lower initial investment and more affordable consumables. DTG's cost per print is often elevated by slower production times and maintenance requirements, while DTF benefits from faster turnaround and less frequent machine servicing, reducing overall operational expenses. For businesses prioritizing volume and cost-efficiency, DTF typically provides a more budget-friendly solution compared to DTG's premium-quality but pricier output.

Durability and Washability of Prints

Direct To Garment (DTG) prints offer excellent washability with vibrant colors that remain intact through numerous washes, though they can gradually fade over time. Direct To Film (DTF) prints provide superior durability, with strong adhesion to fabric fibers and resistance to cracking, peeling, and fading even after extensive laundering. Both methods ensure quality prints, but DTF typically outperforms DTG in terms of long-term print longevity and washability.

Choosing Between DTG and DTF for Your Business

Choosing between Direct To Garment (DTG) and Direct To Film (DTF) depends on factors like production volume, fabric compatibility, and print durability. DTG excels in printing high-detail, vibrant colors directly onto cotton fabrics with shorter runs, while DTF offers versatility across multiple fabric types and better resistance to washing and wear. Prioritize your target market's needs, budget, and available equipment to select the most efficient and cost-effective printing method for your business.

Direct To Garment vs Direct To Film Infographic

libmatt.com

libmatt.com