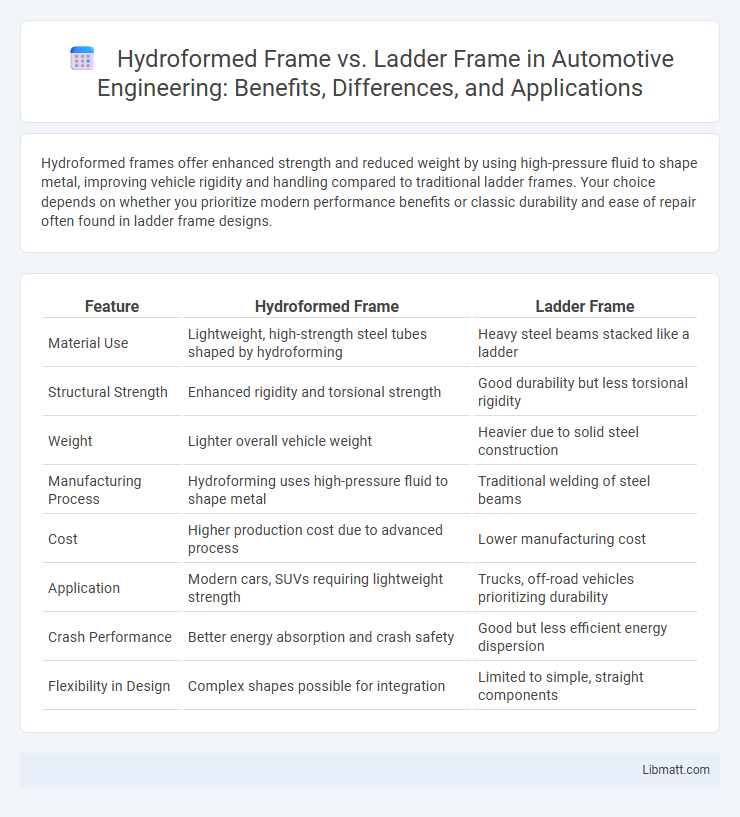

Hydroformed frames offer enhanced strength and reduced weight by using high-pressure fluid to shape metal, improving vehicle rigidity and handling compared to traditional ladder frames. Your choice depends on whether you prioritize modern performance benefits or classic durability and ease of repair often found in ladder frame designs.

Table of Comparison

| Feature | Hydroformed Frame | Ladder Frame |

|---|---|---|

| Material Use | Lightweight, high-strength steel tubes shaped by hydroforming | Heavy steel beams stacked like a ladder |

| Structural Strength | Enhanced rigidity and torsional strength | Good durability but less torsional rigidity |

| Weight | Lighter overall vehicle weight | Heavier due to solid steel construction |

| Manufacturing Process | Hydroforming uses high-pressure fluid to shape metal | Traditional welding of steel beams |

| Cost | Higher production cost due to advanced process | Lower manufacturing cost |

| Application | Modern cars, SUVs requiring lightweight strength | Trucks, off-road vehicles prioritizing durability |

| Crash Performance | Better energy absorption and crash safety | Good but less efficient energy dispersion |

| Flexibility in Design | Complex shapes possible for integration | Limited to simple, straight components |

Introduction to Vehicle Frame Types

Hydroformed frames offer enhanced strength and reduced weight through precision shaping of metal tubes, improving vehicle rigidity and crash safety compared to traditional ladder frames, which consist of two parallel rails connected by crossmembers and provide robust durability for heavy-duty applications. Your choice between hydroformed and ladder frames impacts ride quality, handling, and overall vehicle performance, with hydroformed designs favored in modern passenger cars for efficiency and ladder frames common in trucks for ruggedness. Understanding these differences helps in selecting the optimal frame type based on driving needs and vehicle purpose.

What is a Hydroformed Frame?

A hydroformed frame is a vehicle chassis constructed using high-pressure hydraulic fluid to shape metal tubes into complex, lightweight, and strong structural components. This manufacturing process allows for precise control over frame geometry, resulting in improved rigidity and reduced weight compared to traditional ladder frames. Hydroformed frames enhance vehicle performance, fuel efficiency, and crash safety due to their optimized strength-to-weight ratio.

What is a Ladder Frame?

A ladder frame is a vehicle chassis design consisting of two parallel steel beams connected by several cross members, forming a structure resembling a ladder. This frame type offers high durability and strength, making it ideal for heavy-duty trucks and off-road vehicles. Ladder frames provide excellent load distribution and ease of repair but tend to be heavier and less rigid compared to hydroformed frames.

Structural Differences: Hydroformed vs Ladder Frame

Hydroformed frames are created by shaping metal tubes with high-pressure hydraulic fluid, resulting in smooth, lightweight, and highly rigid structures that improve vehicle strength and crash resistance. Ladder frames consist of two parallel steel beams connected by multiple cross members, offering durability and simplicity but generally higher weight and less torsional stiffness compared to hydroformed frames. The hydroforming process allows for complex shapes and optimized material distribution, enhancing performance, whereas ladder frames rely on conventional welding and heavier materials for robustness.

Strength and Durability Comparison

Hydroformed frames offer superior strength and durability due to their seamless, tubular construction that evenly distributes stress and resists bending and twisting better than traditional ladder frames. Ladder frames, composed of two parallel steel beams connected by cross members, provide strong foundational support but are generally heavier and more susceptible to deformation under heavy loads or impacts. The advanced manufacturing process of hydroforming results in lighter yet more rigid frames, enhancing vehicle performance and longevity compared to conventional ladder frames.

Weight and Efficiency Factors

Hydroformed frames are crafted by shaping metal tubes under high pressure, resulting in lighter and more rigid structures compared to traditional ladder frames made from stacked steel beams. This weight reduction enhances fuel efficiency and improves vehicle handling, making hydroformed frames favorable for performance and modern automotive designs. Your choice between these frame types impacts overall vehicle efficiency, with hydroformed frames offering superior strength-to-weight ratios and optimized energy use.

Impact on Ride Quality and Handling

Hydroformed frames offer enhanced ride quality and handling due to their precise shaping and uniform strength distribution, which reduces flex and improves vehicle rigidity. Ladder frames, typically heavier and less rigid, tend to result in a rougher ride and less responsive handling, especially in off-road conditions. Vehicles with hydroformed frames often experience better vibration dampening and improved cornering stability compared to those with traditional ladder frames.

Cost Implications: Manufacturing and Maintenance

Hydroformed frames, created by shaping metal tubes with high-pressure fluid, generally incur higher initial manufacturing costs due to advanced tooling and precision processes compared to ladder frames, which use simpler, stamped steel sections. Maintenance expenses for hydroformed frames tend to be lower as their integrated, seamless design enhances structural durability and corrosion resistance, reducing the need for repairs. Ladder frames, while cheaper to produce and easier to repair with basic tools, are more prone to rust and fatigue, potentially increasing long-term maintenance costs.

Applications in Modern Vehicles

Hydroformed frames are commonly used in modern passenger cars and SUVs due to their lightweight structure and enhanced rigidity, contributing to improved fuel efficiency and handling. Ladder frames remain prevalent in heavy-duty trucks and off-road vehicles, offering superior durability and load-bearing capacity ideal for rugged terrains and towing applications. The choice between hydroformed and ladder frames depends on vehicle purpose, with hydroforming favored for performance and ladder frames for strength.

Choosing the Right Frame: Key Considerations

Hydroformed frames offer superior strength-to-weight ratios and improved rigidity, making them ideal for performance vehicles and precision handling. Ladder frames excel in durability and load-bearing capacity, preferred for heavy-duty trucks and off-road applications. Your choice depends on priorities such as vehicle weight, structural integrity, and intended use, ensuring optimal balance between performance and durability.

hydroformed frame vs ladder frame Infographic

libmatt.com

libmatt.com