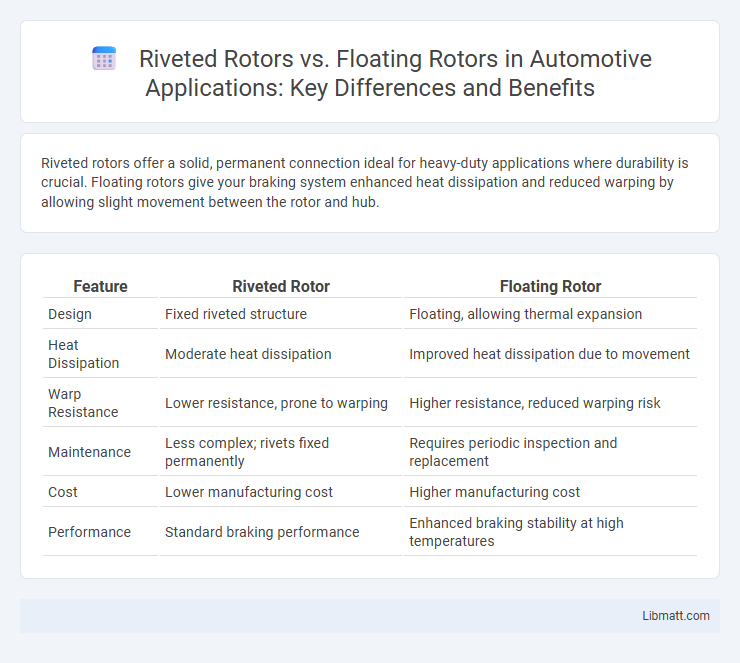

Riveted rotors offer a solid, permanent connection ideal for heavy-duty applications where durability is crucial. Floating rotors give your braking system enhanced heat dissipation and reduced warping by allowing slight movement between the rotor and hub.

Table of Comparison

| Feature | Riveted Rotor | Floating Rotor |

|---|---|---|

| Design | Fixed riveted structure | Floating, allowing thermal expansion |

| Heat Dissipation | Moderate heat dissipation | Improved heat dissipation due to movement |

| Warp Resistance | Lower resistance, prone to warping | Higher resistance, reduced warping risk |

| Maintenance | Less complex; rivets fixed permanently | Requires periodic inspection and replacement |

| Cost | Lower manufacturing cost | Higher manufacturing cost |

| Performance | Standard braking performance | Enhanced braking stability at high temperatures |

Introduction to Riveted and Floating Rotors

Riveted rotors feature blades securely fastened to the hub using rivets, providing a solid and durable connection that ensures consistent performance in various mechanical applications. Floating rotors allow blades some freedom of movement within the hub, enhancing flexibility and reducing stress from mechanical vibrations during operation. Understanding these rotor types helps you select the ideal solution for optimizing efficiency and reliability in your machinery.

What is a Riveted Rotor?

A riveted rotor is a type of brake rotor where the friction material is mechanically attached to the rotor using rivets, providing a secure and durable bond. This design enhances heat dissipation and resistance to wear, making it suitable for high-performance and heavy-duty braking applications. Your choice between riveted and floating rotors depends on factors like vehicle type, driving conditions, and maintenance preferences.

What is a Floating Rotor?

A floating rotor is a type of brake rotor designed to improve heat dissipation and minimize warping under high-stress conditions by allowing slight lateral movement between the braking surface and the hub. This rotor configuration typically consists of two metal discs connected by rivets or pins, enabling controlled flex and reducing thermal distortion during intense braking. Floating rotors are favored in high-performance and racing applications for their enhanced durability and consistent braking performance compared to riveted rotors.

Key Differences Between Riveted and Floating Rotors

Riveted rotors are fixed securely to the hub with rivets, providing a robust and permanent connection that enhances overall durability under heavy braking conditions. Floating rotors consist of a separate rotor ring and hat connected by a series of floating pins or bobbins, allowing for thermal expansion and reducing warping during high-performance use. Your choice between riveted and floating rotors impacts braking performance, heat dissipation, and long-term reliability based on driving style and vehicle demands.

Performance Comparison: Riveted vs Floating Rotors

Riveted rotors exhibit superior durability and stability under high-pressure braking conditions due to their fixed construction, offering consistent performance in heavy-duty applications. Floating rotors provide enhanced heat dissipation and reduced brake fade by allowing lateral movement, making them ideal for high-performance and racing scenarios. Performance comparison highlights riveted rotors' reliability in prolonged stress environments, while floating rotors optimize thermal management and responsiveness for aggressive driving styles.

Durability and Heat Dissipation

Riveted rotors offer enhanced durability due to their solid construction, which reduces the risk of deformation under heavy braking conditions. Floating rotors excel in heat dissipation because their two-piece design allows thermal expansion and contraction, minimizing warping and maintaining consistent braking performance. The improved heat management of floating rotors generally leads to longer lifespan and reduced brake fade compared to riveted rotors.

Maintenance and Longevity

Riveted rotors require more frequent inspection and maintenance due to potential loosening of rivets over time, which can reduce their operational lifespan. Floating rotors offer improved durability and longer service life as they accommodate thermal expansion and reduce stress on braking components. Choosing floating rotors can enhance your vehicle's maintenance intervals and overall longevity.

Cost and Value Considerations

Riveted rotors typically offer lower initial manufacturing costs due to simpler assembly processes, making them a cost-effective choice for budget-sensitive applications. Floating rotors, however, provide enhanced performance and longevity, delivering better value over time through improved heat dissipation and reduced wear. The decision between riveted and floating rotors balances upfront savings against long-term durability and maintenance expenses.

Applications and Best Use Cases

Riveted rotors offer enhanced structural integrity and are ideal for heavy-duty applications requiring high mechanical strength, such as industrial machinery and large electric motors. Floating rotors provide superior thermal management and reduced vibration, making them best suited for high-speed, precision equipment like aerospace generators and advanced automotive systems. Your choice depends on whether durability or performance efficiency is the primary requirement in your application.

Choosing the Right Rotor for Your Needs

Selecting the appropriate rotor involves evaluating the benefits of riveted rotors, known for their robust construction and long-lasting durability, against floating rotors, which offer improved heat dissipation and reduced brake fade. Riveted rotors suit heavy-duty applications requiring consistent performance under high stress, while floating rotors excel in high-performance vehicles demanding better thermal management and precision. Understanding these distinctions ensures optimal braking efficiency tailored to specific driving conditions and maintenance preferences.

Riveted rotor vs Floating rotor Infographic

libmatt.com

libmatt.com