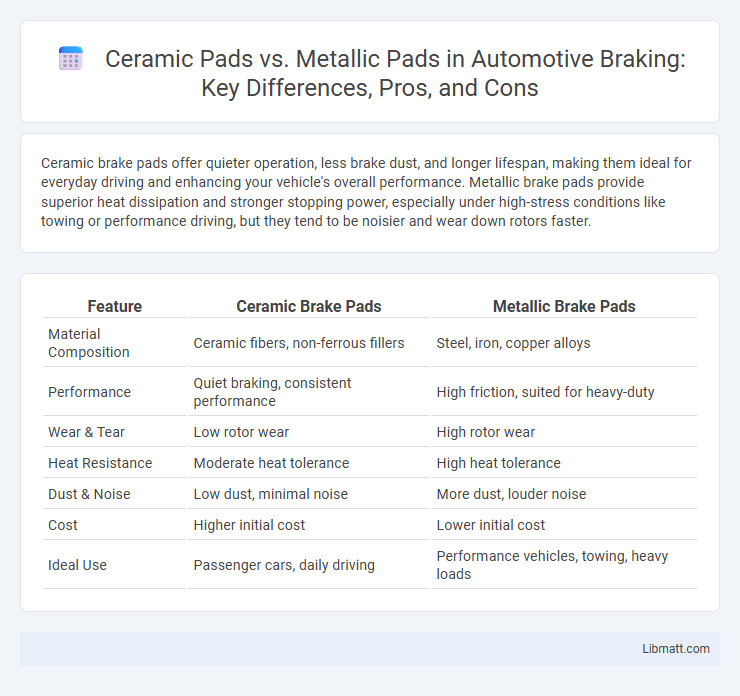

Ceramic brake pads offer quieter operation, less brake dust, and longer lifespan, making them ideal for everyday driving and enhancing your vehicle's overall performance. Metallic brake pads provide superior heat dissipation and stronger stopping power, especially under high-stress conditions like towing or performance driving, but they tend to be noisier and wear down rotors faster.

Table of Comparison

| Feature | Ceramic Brake Pads | Metallic Brake Pads |

|---|---|---|

| Material Composition | Ceramic fibers, non-ferrous fillers | Steel, iron, copper alloys |

| Performance | Quiet braking, consistent performance | High friction, suited for heavy-duty |

| Wear & Tear | Low rotor wear | High rotor wear |

| Heat Resistance | Moderate heat tolerance | High heat tolerance |

| Dust & Noise | Low dust, minimal noise | More dust, louder noise |

| Cost | Higher initial cost | Lower initial cost |

| Ideal Use | Passenger cars, daily driving | Performance vehicles, towing, heavy loads |

Introduction to Ceramic and Metallic Brake Pads

Ceramic brake pads are made from dense ceramic fibers combined with filler materials and bonding agents, offering quieter operation and less brake dust compared to metallic brake pads. Metallic brake pads consist of a mixture of metals such as steel, copper, and iron, providing superior heat dissipation and durability, especially under high-performance or heavy-duty conditions. Understanding the differences in material composition helps you choose brake pads that best suit your vehicle's driving requirements and maintenance preferences.

Composition and Material Differences

Ceramic brake pads consist of dense ceramic fibers, nonferrous fillers, and bonding agents, providing quieter operation and less brake dust compared to metallic pads. Metallic brake pads are made from a combination of iron, copper, steel, and graphite compounds, offering superior heat dissipation and durability for high-performance braking. The material differences impact thermal stability, noise levels, and wear rates, influencing vehicle braking efficiency and maintenance needs.

Performance in Various Driving Conditions

Ceramic brake pads offer superior performance in everyday driving conditions, providing quieter operation and reduced brake dust, making them ideal for city and highway use. Metallic pads deliver better heat resistance and improved stopping power under high-stress conditions, such as aggressive driving or towing, ensuring reliable performance in demanding environments. Your choice depends on balancing comfort for daily commutes with enhanced durability and braking efficiency during intense driving scenarios.

Noise and Vibration Comparison

Ceramic brake pads generate less noise and vibration compared to metallic pads due to their denser composition and advanced friction materials. Metallic pads often produce louder squealing and harsher vibrations, especially under heavy braking, because of their metal fibers and adhesive resins. Choosing ceramic pads can significantly enhance Your driving comfort by minimizing brake noise and reducing vibrations.

Brake Dust and Cleanliness

Ceramic brake pads produce significantly less brake dust compared to metallic pads, resulting in cleaner wheels and less frequent cleaning. Their dust is finer and lighter in color, making it less noticeable and easier to remove. Choosing ceramic pads helps maintain your vehicle's appearance by minimizing brake dust buildup.

Durability and Lifespan

Ceramic brake pads typically offer a longer lifespan compared to metallic pads due to their stable compound that resists wear and tear under various driving conditions. Metallic pads, while providing excellent heat dissipation and strong braking power, tend to wear faster because of their abrasive nature and higher metal content. Drivers prioritizing durability often choose ceramic pads for their quieter operation and reduced rotor wear, extending overall brake system longevity.

Heat Resistance and Fade Performance

Ceramic brake pads offer superior heat resistance compared to metallic pads, maintaining stable performance under high-temperature conditions and reducing the risk of brake fade during prolonged or intense braking. Metallic pads, while providing strong initial bite and durability, tend to overheat more quickly, leading to faster fade performance deterioration over time. Choosing ceramic pads can enhance your vehicle's braking reliability by delivering consistent stopping power and minimizing heat-induced wear.

Cost and Value Considerations

Ceramic brake pads generally cost more upfront than metallic pads but offer longer lifespan and quieter performance, providing better value over time for your vehicle maintenance. Metallic pads, while cheaper initially, tend to wear faster and can cause more rotor wear, potentially increasing overall replacement costs. Evaluating your driving habits and budget helps determine if the higher initial investment for ceramic pads translates into cost savings and improved braking performance tailored to your needs.

Environmental Impact

Ceramic brake pads generate less dust and release fewer toxic metals into the environment compared to metallic pads, reducing pollution and health hazards. Their longer lifespan minimizes waste, supporting sustainable vehicle maintenance. In contrast, metallic pads tend to wear faster, producing more particulate matter and contributing to higher environmental contamination.

Choosing the Right Brake Pad for Your Vehicle

Selecting the ideal brake pad for your vehicle involves understanding the key differences between ceramic and metallic pads. Ceramic brake pads offer quieter operation, less dust, and longer lifespan, making them suitable for everyday driving and lighter vehicles. Metallic brake pads provide superior heat dissipation and enhanced stopping power, ideal for performance cars or towing heavy loads, ensuring your safety and optimal braking performance.

Ceramic pad vs Metallic pad Infographic

libmatt.com

libmatt.com