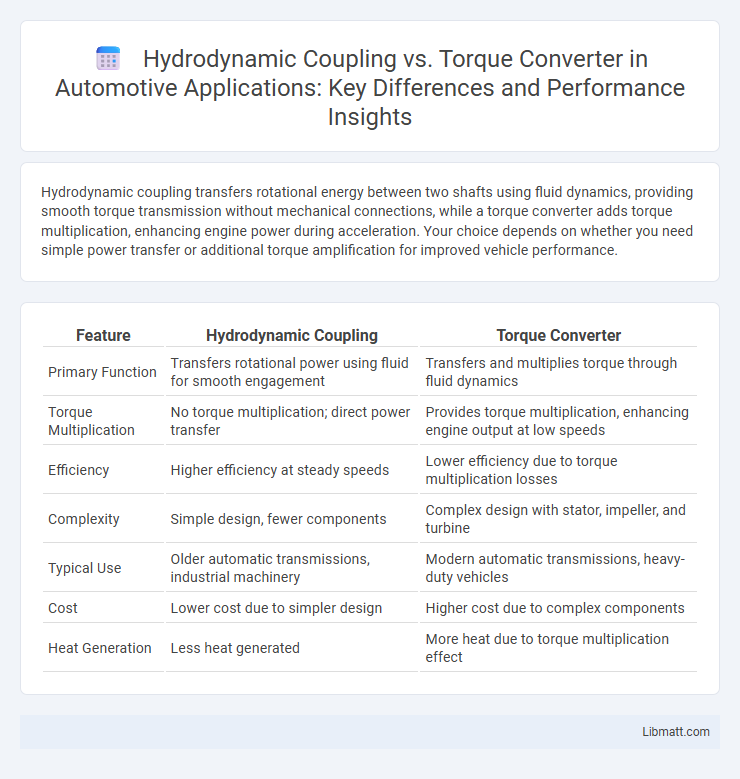

Hydrodynamic coupling transfers rotational energy between two shafts using fluid dynamics, providing smooth torque transmission without mechanical connections, while a torque converter adds torque multiplication, enhancing engine power during acceleration. Your choice depends on whether you need simple power transfer or additional torque amplification for improved vehicle performance.

Table of Comparison

| Feature | Hydrodynamic Coupling | Torque Converter |

|---|---|---|

| Primary Function | Transfers rotational power using fluid for smooth engagement | Transfers and multiplies torque through fluid dynamics |

| Torque Multiplication | No torque multiplication; direct power transfer | Provides torque multiplication, enhancing engine output at low speeds |

| Efficiency | Higher efficiency at steady speeds | Lower efficiency due to torque multiplication losses |

| Complexity | Simple design, fewer components | Complex design with stator, impeller, and turbine |

| Typical Use | Older automatic transmissions, industrial machinery | Modern automatic transmissions, heavy-duty vehicles |

| Cost | Lower cost due to simpler design | Higher cost due to complex components |

| Heat Generation | Less heat generated | More heat due to torque multiplication effect |

Introduction to Power Transmission in Vehicles

Hydrodynamic coupling and torque converters are essential components in vehicle power transmission systems, enabling smooth transfer of engine power to the drivetrain by using fluid dynamics. While hydrodynamic couplings primarily provide slip and cushioning to absorb shock loads between the engine and transmission, torque converters enhance this function by incorporating a stator to increase torque multiplication during acceleration. Understanding these differences helps you optimize vehicle performance and efficiency in various driving conditions.

What is Hydrodynamic Coupling?

Hydrodynamic coupling is a fluid-based device used to transmit rotational power between two shafts without direct mechanical contact, relying on the kinetic energy of fluid to transfer torque smoothly. Unlike a torque converter, which multiplies torque, a hydrodynamic coupling primarily provides slip and dampening, improving the start-up and engagement performance in vehicle drivetrains. Your choice between the two depends on the need for torque multiplication versus simple power transfer.

What is a Torque Converter?

A torque converter is a hydrodynamic device used in automatic transmissions to transfer and multiply engine torque to the transmission input shaft, enabling smooth vehicle acceleration without manual clutch engagement. It consists of three main components: the impeller, turbine, and stator, which work together to convert engine power into rotational force through fluid dynamics. Your vehicle benefits from reduced transmission wear and improved drivability due to the torque converter's ability to adapt torque output based on driving conditions.

Key Components: Hydrodynamic Coupling vs Torque Converter

Hydrodynamic couplings primarily consist of an impeller and a turbine enclosed in a single housing, facilitating fluid transfer of torque without mechanical connection. Torque converters include these components plus a stator, which redirects fluid flow to increase torque multiplication during vehicle acceleration. The stator's presence in torque converters distinguishes them by providing enhanced torque transfer efficiency compared to the simpler hydrodynamic coupling design.

Working Principles: Fluid Dynamics in Action

Hydrodynamic coupling and torque converters both utilize fluid dynamics to transmit rotational power, but their working principles differ significantly. Hydrodynamic coupling transfers torque through a fluid medium between an impeller and a turbine, allowing slip and smooth power transmission without torque multiplication. In contrast, a torque converter incorporates a stator along with the impeller and turbine, using fluid dynamics to multiply torque during acceleration by redirecting the fluid flow, enhancing engine output to the drivetrain.

Efficiency Comparison: Power Loss and Heat Generation

Hydrodynamic couplings typically exhibit higher power loss and heat generation due to continuous slip between the impeller and turbine, resulting in lower overall efficiency compared to torque converters. Torque converters incorporate a stator that redirects fluid flow, reducing slip and improving torque multiplication, which enhances efficiency by minimizing energy wastage and heat buildup. This design allows torque converters to operate more effectively under varying load conditions, making them preferable in automotive transmissions for better fuel economy.

Applications in Automotive and Industrial Sectors

Hydrodynamic couplings are widely used in industrial sectors for smooth power transmission in heavy machinery, conveyor systems, and pumps, providing slip-controlled torque transfer that reduces mechanical stress. Torque converters dominate automotive applications, particularly in automatic transmissions, enabling efficient torque multiplication and smooth gear shifts by hydraulically coupling the engine to the drivetrain. Understanding these differences helps you choose the right technology for applications requiring variable torque and speed control in both vehicles and industrial equipment.

Advantages and Disadvantages of Hydrodynamic Coupling

Hydrodynamic coupling offers smooth torque transmission and reduces shock loads in drivetrains, which enhances the longevity of mechanical components and improves ride comfort. It lacks torque multiplication, resulting in less efficient power transfer during acceleration compared to a torque converter, potentially causing slower vehicle responsiveness. Your choice of hydrodynamic coupling benefits applications requiring steady power delivery but may not suit scenarios demanding rapid torque amplification.

Torque Converter Benefits and Limitations

Torque converters provide smooth power transfer and torque multiplication, enhancing vehicle acceleration and fuel efficiency in automatic transmissions. They offer better protection to the drivetrain by absorbing shocks and vibrations but can result in some energy loss due to fluid friction, reducing overall efficiency compared to direct mechanical coupling. Despite improvements like lock-up clutches to minimize slippage, torque converters may still exhibit reduced performance in applications requiring precise torque control.

Future Trends: Innovations in Fluid Power Transmission

Innovations in fluid power transmission are driving advancements in both hydrodynamic coupling and torque converters by enhancing efficiency and responsiveness through adaptive control systems and improved fluid dynamics. Emerging trends leverage smart materials and real-time monitoring to optimize torque transfer while reducing energy loss, ensuring smoother power delivery for electric and hybrid vehicles. Your vehicle's performance can benefit significantly from these future technologies, which prioritize durability and energy conservation in dynamic driving conditions.

Hydrodynamic Coupling vs Torque Converter Infographic

libmatt.com

libmatt.com