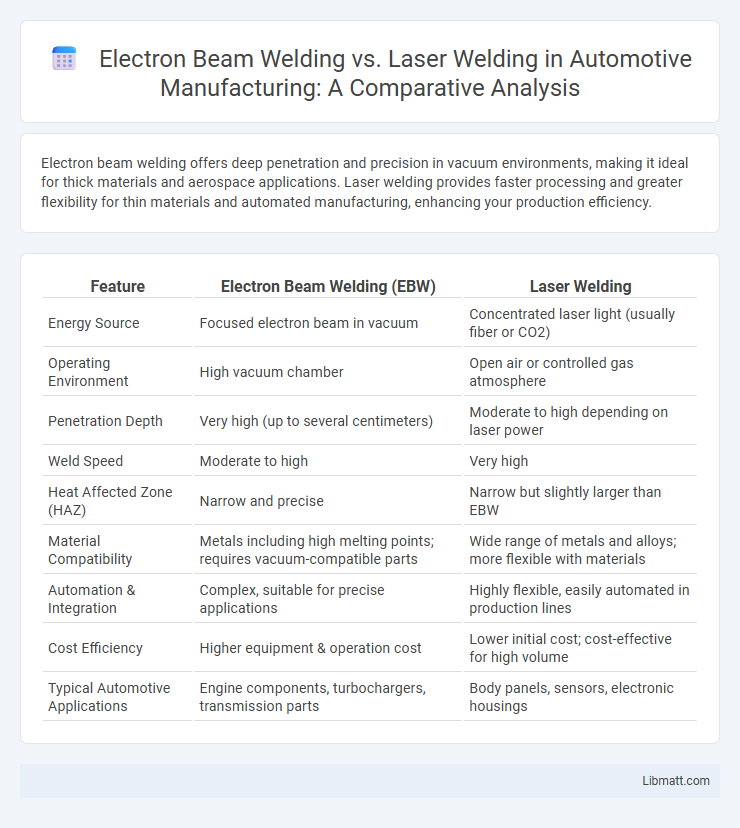

Electron beam welding offers deep penetration and precision in vacuum environments, making it ideal for thick materials and aerospace applications. Laser welding provides faster processing and greater flexibility for thin materials and automated manufacturing, enhancing your production efficiency.

Table of Comparison

| Feature | Electron Beam Welding (EBW) | Laser Welding |

|---|---|---|

| Energy Source | Focused electron beam in vacuum | Concentrated laser light (usually fiber or CO2) |

| Operating Environment | High vacuum chamber | Open air or controlled gas atmosphere |

| Penetration Depth | Very high (up to several centimeters) | Moderate to high depending on laser power |

| Weld Speed | Moderate to high | Very high |

| Heat Affected Zone (HAZ) | Narrow and precise | Narrow but slightly larger than EBW |

| Material Compatibility | Metals including high melting points; requires vacuum-compatible parts | Wide range of metals and alloys; more flexible with materials |

| Automation & Integration | Complex, suitable for precise applications | Highly flexible, easily automated in production lines |

| Cost Efficiency | Higher equipment & operation cost | Lower initial cost; cost-effective for high volume |

| Typical Automotive Applications | Engine components, turbochargers, transmission parts | Body panels, sensors, electronic housings |

Introduction to Electron Beam Welding and Laser Welding

Electron beam welding (EBW) utilizes a high-velocity beam of electrons focused on the workpiece, generating intense heat that allows deep, narrow welds with minimal distortion in metals like titanium and stainless steel. Laser welding employs concentrated light energy, typically from a fiber or CO2 laser, to achieve precise, high-speed fusion, making it ideal for delicate applications such as microelectronics and automotive components. Both techniques offer advantages in welding thickness, speed, and heat input control, with EBW requiring vacuum conditions and laser welding often operating in open air.

Fundamental Principles of Each Welding Method

Electron beam welding utilizes a high-velocity beam of electrons focused on the workpiece, generating intense heat through kinetic energy conversion for precise and deep welds. Laser welding employs a concentrated light beam, usually from a solid-state or fiber laser, to melt and fuse materials with high accuracy and minimal thermal distortion. Both methods operate in controlled environments to optimize energy delivery and weld quality, but electron beam welding requires a vacuum chamber, while laser welding can be performed in open air or controlled atmospheres.

Equipment and Setup Comparison

Electron beam welding requires a vacuum chamber and specialized electron beam gun, making its equipment more complex and bulkier compared to laser welding, which uses compact fiber or CO2 lasers allowing for more flexible setups. Laser welding setups offer easier integration into automated production lines with adjustable beam parameters for precision, while electron beam welding demands intricate vacuum maintenance and precise beam alignment. Your choice depends on the necessity for high precision and penetration depth versus equipment portability and operational convenience.

Process Efficiency and Speed

Electron beam welding offers superior penetration and minimal heat distortion, enhancing process efficiency for thick materials, while laser welding provides greater speed and precision, making it ideal for thinner sections and delicate components. Your choice depends on the material thickness and component complexity, as electron beam welding excels in deep welds whereas laser welding achieves higher throughput in high-volume production. Both methods optimize manufacturing speed and quality, but laser welding generally supports faster cycle times with less post-processing required.

Material Suitability and Versatility

Electron beam welding excels in joining thick and high-strength materials such as titanium, stainless steel, and nickel alloys due to its deep penetration and vacuum environment, which minimizes contamination. Laser welding offers greater versatility for thin metals, reflective materials, and complex geometries, allowing precise control and high-speed processing in ambient conditions. Both technologies require careful parameter optimization to achieve optimal weld quality depending on material type and thickness.

Joint Quality and Precision

Electron beam welding offers exceptionally deep penetration and minimal distortion, producing high-strength joints ideal for thick materials and aerospace components. Laser welding provides superior precision with a finer focus, enabling excellent control for intricate, delicate joints and thin materials used in microelectronics and medical device manufacturing. Both techniques ensure high joint quality but differ in heat input management and accessibility to complex geometries, influencing their suitability across various industrial applications.

Penetration Depth and Weld Strength

Electron beam welding offers significantly deeper penetration compared to laser welding, making it ideal for thick materials requiring strong, precise joints. The concentrated energy of electron beams enables weld strengths that often surpass those of laser welds, especially in high-performance aerospace and automotive applications. Your choice between these methods should consider the trade-offs in penetration depth and weld integrity to ensure optimal results for your specific projects.

Cost Analysis: Investment and Operation

Electron beam welding requires significant initial investment in vacuum chambers and electron beam generators, while laser welding systems demand high-cost laser sources and precision optics. Operational costs for electron beam welding include expensive vacuum maintenance and slower processing times, whereas laser welding offers faster throughput but higher energy consumption. Your choice depends on balancing upfront capital against ongoing expenses and the specific production volume needs.

Typical Applications Across Industries

Electron beam welding excels in aerospace and automotive industries due to its precision and deep penetration, making it ideal for manufacturing turbine blades, fuel injectors, and transmission components. Laser welding is commonly used in electronics, medical device production, and jewelry, providing fast, high-quality welds for delicate parts such as circuit boards, surgical instruments, and fine metalwork. Both techniques are essential in shipbuilding and heavy equipment manufacturing for their ability to weld thick materials with minimal thermal distortion.

Choosing the Right Welding Technique

Electron beam welding offers deep penetration and a narrow weld zone, making it ideal for thick materials and aerospace applications requiring high precision. Laser welding provides faster processing speeds and greater flexibility for thin materials and intricate designs in automotive and electronics manufacturing. Selecting the right welding technique depends on factors such as material thickness, joint configuration, heat input control, and production volume.

electron beam welding vs laser welding Infographic

libmatt.com

libmatt.com