Wideband O2 sensors provide precise air-fuel ratio measurements across a broad range, enabling your engine management system to optimize combustion for improved efficiency and reduced emissions, while narrowband sensors only indicate if the mixture is rich or lean relative to stoichiometric levels. Choosing a wideband sensor enhances performance tuning and diagnostic accuracy, whereas narrowband sensors are simpler and typically used in older or less complex vehicle systems.

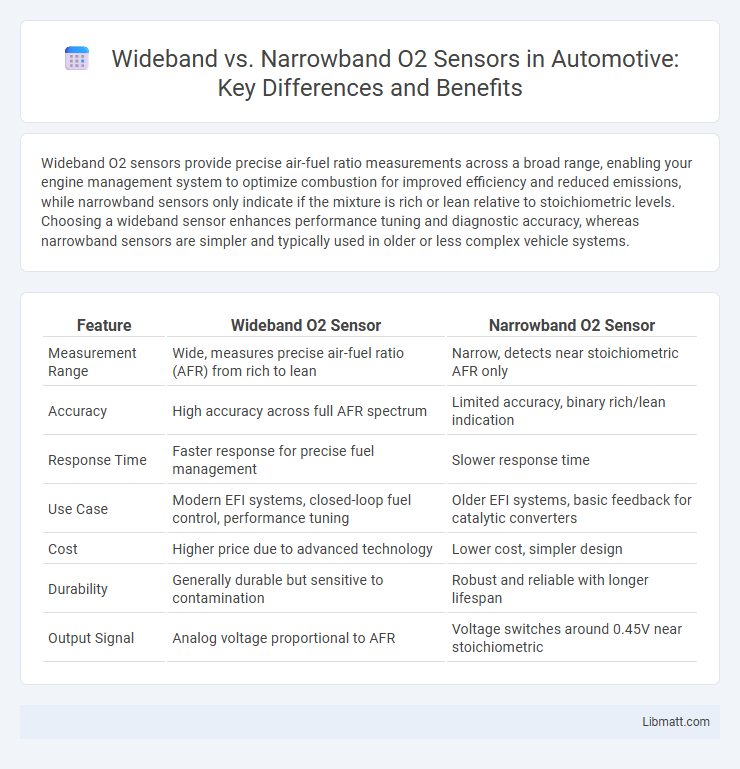

Table of Comparison

| Feature | Wideband O2 Sensor | Narrowband O2 Sensor |

|---|---|---|

| Measurement Range | Wide, measures precise air-fuel ratio (AFR) from rich to lean | Narrow, detects near stoichiometric AFR only |

| Accuracy | High accuracy across full AFR spectrum | Limited accuracy, binary rich/lean indication |

| Response Time | Faster response for precise fuel management | Slower response time |

| Use Case | Modern EFI systems, closed-loop fuel control, performance tuning | Older EFI systems, basic feedback for catalytic converters |

| Cost | Higher price due to advanced technology | Lower cost, simpler design |

| Durability | Generally durable but sensitive to contamination | Robust and reliable with longer lifespan |

| Output Signal | Analog voltage proportional to AFR | Voltage switches around 0.45V near stoichiometric |

Introduction to O2 Sensors

O2 sensors, essential for monitoring exhaust gases in combustion engines, come in two primary types: wideband and narrowband. Narrowband O2 sensors measure oxygen levels within a limited range, providing a simple lean or rich signal crucial for basic engine control systems. Wideband O2 sensors deliver a precise, continuous air-fuel ratio measurement across a broader spectrum, enabling advanced fuel management and improved emissions performance.

What is a Narrowband O2 Sensor?

A narrowband O2 sensor measures oxygen concentration in the exhaust gases by producing a voltage signal that rapidly switches between rich and lean conditions around the stoichiometric air-fuel ratio (14.7:1 for gasoline engines). This sensor type provides limited resolution since it only indicates whether the mixture is richer or leaner than the ideal ratio, enabling basic feedback for fuel control systems. Narrowband sensors are less precise compared to wideband O2 sensors, which continuously measure a broader range of air-fuel ratios with higher accuracy.

What is a Wideband O2 Sensor?

A wideband O2 sensor measures the oxygen content in exhaust gases with a broad air-fuel ratio range, providing precise and real-time feedback to the engine control unit (ECU) for optimal combustion efficiency. Unlike narrowband sensors that only indicate whether the mixture is rich or lean around the stoichiometric point, wideband sensors deliver accurate quantitative data across rich and lean conditions. This enhanced accuracy improves fuel economy, reduces emissions, and supports advanced engine tuning and diagnostics.

Key Differences Between Wideband and Narrowband Sensors

Wideband O2 sensors provide a broader range of air-fuel ratio measurements with high accuracy, enabling precise engine tuning and efficient emissions control. Narrowband sensors detect only whether the mixture is rich or lean relative to stoichiometric air-fuel ratio, offering less detailed data primarily for basic feedback loop adjustments. Your choice between wideband and narrowband sensors impacts diagnostics, performance monitoring, and fuel management effectiveness in modern vehicles.

How Narrowband O2 Sensors Work

Narrowband O2 sensors operate by measuring oxygen content in exhaust gases through a zirconia ceramic element that generates a voltage signal based on the difference in oxygen concentration between the exhaust and ambient air. This voltage fluctuates rapidly around a stoichiometric ratio of approximately 14.7:1 air-to-fuel, allowing the sensor to signal whether the engine is running rich or lean. Due to their binary output, narrowband sensors are most effective for maintaining precise fuel mixture control but lack the detailed data range offered by wideband sensors.

How Wideband O2 Sensors Work

Wideband O2 sensors function by using a pump cell to maintain a precise oxygen concentration in the sensor's measuring chamber, allowing for accurate detection across a broad range of air-fuel ratios. Unlike narrowband sensors that only indicate stoichiometric combustion, wideband sensors measure the exact ratio of oxygen in the exhaust gases, providing real-time feedback for optimal engine tuning. This precise measurement supports improved fuel efficiency, reduced emissions, and enhanced engine performance.

Performance and Accuracy Comparison

Wideband O2 sensors provide superior performance and accuracy by measuring a wide range of air-fuel ratios, enabling precise fuel mixture adjustments for optimal engine efficiency. Narrowband sensors, limited to detecting stoichiometric points, offer less precise readings, making them less effective for fine-tuning performance or emissions control. Your engine management system benefits more from wideband sensors due to their ability to deliver real-time, detailed data that enhances combustion control and reduces fuel consumption.

Applications: When to Use Wideband or Narrowband

Wideband O2 sensors are ideal for precise air-fuel ratio measurements in modern engines, offering accurate data for performance tuning, emissions control, and fuel efficiency optimization. Narrowband sensors are suitable for basic engine management and diagnostics in older vehicles or systems requiring less detailed oxygen level information. You should choose wideband sensors when accurate real-time feedback is crucial for advanced engine control, while narrowband sensors suffice for simpler monitoring tasks.

Cost and Installation Considerations

Wideband O2 sensors, typically costing between $100 and $300, require more complex installation processes due to their advanced electronics and integrated heater elements, making professional installation recommended. Narrowband O2 sensors are generally less expensive, often priced around $20 to $50, and feature simpler designs that allow for easier DIY installation in most vehicles. The higher cost and installation complexity of wideband sensors are justified by their precise air-fuel ratio measurement, crucial for modern engine management systems and emissions control.

Choosing the Right O2 Sensor for Your Vehicle

Choosing the right O2 sensor for your vehicle significantly impacts engine performance and fuel efficiency. Wideband O2 sensors provide precise air-fuel ratio measurements across a broad range, ideal for modern engines and tuning applications, while narrowband sensors offer simpler, less accurate feedback primarily used in older vehicles. Your selection should consider vehicle type, engine management system, and the desired accuracy for optimal emissions control and fuel economy.

wideband vs narrowband O2 sensor Infographic

libmatt.com

libmatt.com