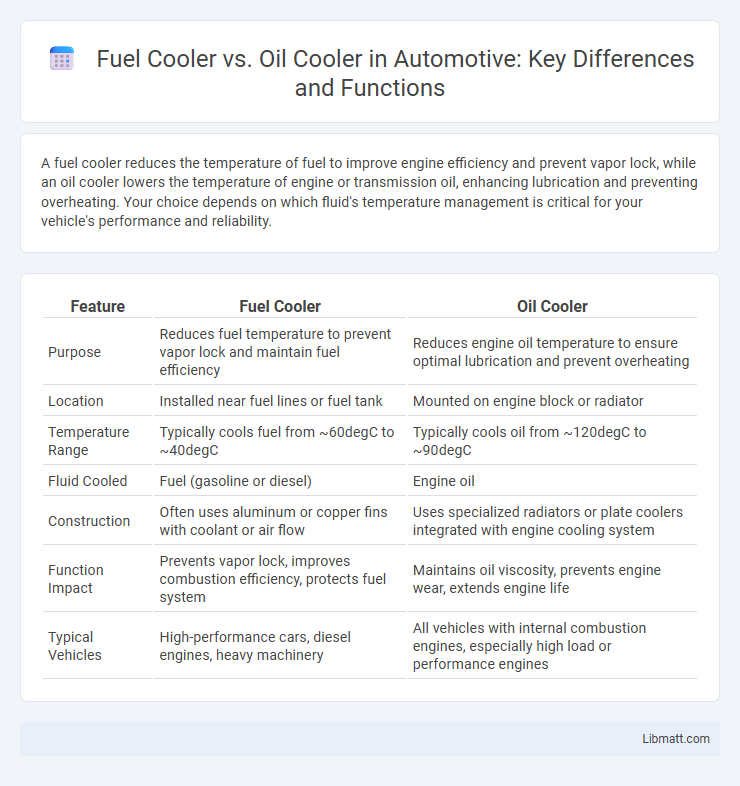

A fuel cooler reduces the temperature of fuel to improve engine efficiency and prevent vapor lock, while an oil cooler lowers the temperature of engine or transmission oil, enhancing lubrication and preventing overheating. Your choice depends on which fluid's temperature management is critical for your vehicle's performance and reliability.

Table of Comparison

| Feature | Fuel Cooler | Oil Cooler |

|---|---|---|

| Purpose | Reduces fuel temperature to prevent vapor lock and maintain fuel efficiency | Reduces engine oil temperature to ensure optimal lubrication and prevent overheating |

| Location | Installed near fuel lines or fuel tank | Mounted on engine block or radiator |

| Temperature Range | Typically cools fuel from ~60degC to ~40degC | Typically cools oil from ~120degC to ~90degC |

| Fluid Cooled | Fuel (gasoline or diesel) | Engine oil |

| Construction | Often uses aluminum or copper fins with coolant or air flow | Uses specialized radiators or plate coolers integrated with engine cooling system |

| Function Impact | Prevents vapor lock, improves combustion efficiency, protects fuel system | Maintains oil viscosity, prevents engine wear, extends engine life |

| Typical Vehicles | High-performance cars, diesel engines, heavy machinery | All vehicles with internal combustion engines, especially high load or performance engines |

Introduction to Fuel Coolers and Oil Coolers

Fuel coolers regulate the temperature of fuel to prevent vapor lock and ensure efficient combustion in engines, while oil coolers maintain optimal engine oil temperature to avoid overheating and preserve lubrication performance. Both systems are essential for engine longevity and performance, with fuel coolers typically integrated into fuel lines and oil coolers often positioned near the radiator or engine block. Understanding the roles of fuel coolers and oil coolers helps you optimize your vehicle's thermal management and prevent costly engine damage.

Purpose and Importance of Cooling Systems

Fuel coolers reduce the temperature of fuel before it enters the engine, preventing vapor lock and maintaining optimal combustion efficiency. Oil coolers dissipate heat from engine oil, ensuring proper lubrication and preventing overheating that can damage engine components. Proper functioning of these cooling systems is crucial for maintaining engine performance, reliability, and longevity.

How Fuel Coolers Work

Fuel coolers work by dissipating heat from heated fuel to maintain optimal engine temperature and prevent vapor lock, using a heat exchanger where fuel flows through tubes surrounded by cooling fluid or air. The design ensures efficient thermal transfer, helping to keep fuel viscosity stable and improving combustion efficiency. Unlike oil coolers that regulate engine oil temperature, fuel coolers specifically target the temperature of the fuel before it enters the combustion chamber.

How Oil Coolers Operate

Oil coolers operate by circulating engine oil through a series of tubes or plates exposed to a cooling medium, typically air or coolant, which dissipates heat away from the oil. This process helps maintain optimal oil temperature, preventing overheating and ensuring effective lubrication of engine components. Your vehicle's oil cooler plays a critical role in sustaining engine efficiency and prolonging the lifespan of internal parts by regulating oil temperature under various operating conditions.

Key Differences between Fuel Coolers and Oil Coolers

Fuel coolers primarily regulate the temperature of fuel to prevent vapor lock and maintain optimal combustion efficiency, whereas oil coolers manage engine oil temperature to ensure proper lubrication and prevent overheating. Fuel coolers are designed to tolerate and dissipate heat from volatile fuels, often positioned near heat sources like the engine or exhaust, while oil coolers handle higher viscosity fluids and are typically placed in locations with adequate airflow such as radiators. The materials and construction differ with fuel coolers emphasizing corrosion resistance to fuel, and oil coolers focusing on thermal conductivity and durability under pressure.

Applications in Automotive and Industrial Machinery

Fuel coolers enhance engine efficiency and performance by maintaining optimal fuel temperature in high-performance automotive engines and heavy industrial machinery such as generators and compressors. Oil coolers improve lubrication system reliability and prevent overheating in automotive transmissions, hydraulic systems, and industrial gearboxes, ensuring extended component lifespan. Both coolers are critical for thermal management in vehicles and equipment subjected to intense operating conditions.

Benefits of Using Fuel Coolers

Fuel coolers improve engine efficiency by lowering the temperature of the fuel before combustion, which enhances combustion stability and reduces engine knocking. By preventing fuel overheating, they protect sensitive components and extend the lifespan of your fuel system. Using a fuel cooler also helps maintain optimal fuel density, leading to better power output and reduced emissions.

Advantages of Oil Coolers

Oil coolers enhance engine performance by efficiently lowering oil temperature, preventing overheating and prolonging engine life. They maintain optimal lubrication viscosity, reducing friction and wear in critical engine components under high stress. Compared to fuel coolers, oil coolers provide superior thermal management for engine oil, ensuring better heat dissipation and improved overall reliability.

Factors to Consider When Choosing Between Fuel and Oil Coolers

Selecting between fuel coolers and oil coolers depends heavily on the specific thermal management requirements of the engine and system design. Key factors include fluid compatibility, operating temperature ranges, flow rates, and the cooling system's placement within the vehicle or machinery. Material durability, maintenance accessibility, and the potential impact on engine performance also influence the optimal choice for heat dissipation efficiency.

Maintenance and Troubleshooting Tips for Coolers

Fuel coolers and oil coolers require regular inspection to prevent leaks, corrosion, and blockages that can reduce thermal efficiency and cause overheating. Maintaining clean, debris-free cooling fins and checking for proper fluid flow ensures optimal performance, while troubleshooting common issues involves monitoring temperature variations and pressure drops in your system. Implementing scheduled maintenance routines and promptly addressing irregularities can extend cooler lifespan and improve engine reliability.

Fuel cooler vs Oil cooler Infographic

libmatt.com

libmatt.com