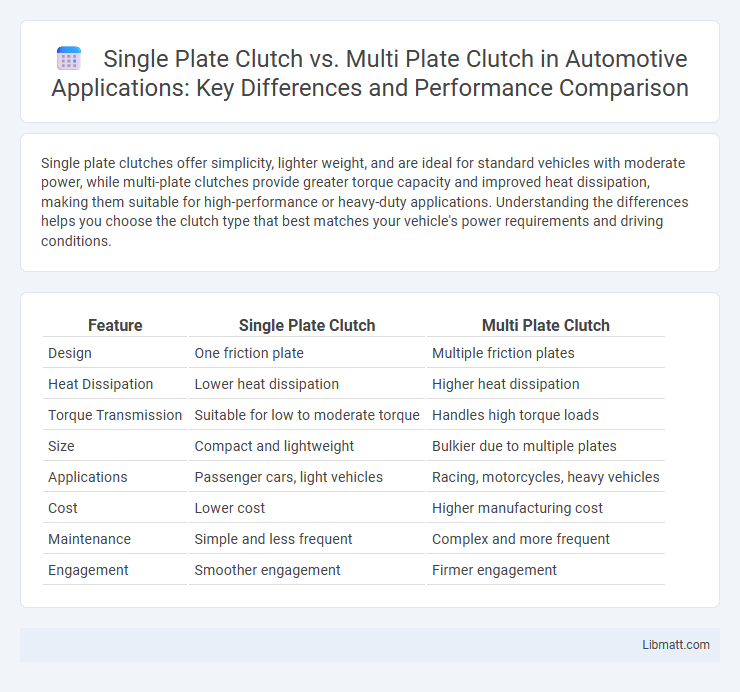

Single plate clutches offer simplicity, lighter weight, and are ideal for standard vehicles with moderate power, while multi-plate clutches provide greater torque capacity and improved heat dissipation, making them suitable for high-performance or heavy-duty applications. Understanding the differences helps you choose the clutch type that best matches your vehicle's power requirements and driving conditions.

Table of Comparison

| Feature | Single Plate Clutch | Multi Plate Clutch |

|---|---|---|

| Design | One friction plate | Multiple friction plates |

| Heat Dissipation | Lower heat dissipation | Higher heat dissipation |

| Torque Transmission | Suitable for low to moderate torque | Handles high torque loads |

| Size | Compact and lightweight | Bulkier due to multiple plates |

| Applications | Passenger cars, light vehicles | Racing, motorcycles, heavy vehicles |

| Cost | Lower cost | Higher manufacturing cost |

| Maintenance | Simple and less frequent | Complex and more frequent |

| Engagement | Smoother engagement | Firmer engagement |

Introduction to Clutch Systems

Clutch systems are essential components in vehicles, enabling smooth transmission of power from the engine to the drivetrain. Single plate clutches feature one friction disc, providing efficient torque transfer and simpler maintenance, making them ideal for standard passenger cars. Multi plate clutches contain multiple friction discs stacked together, allowing higher torque capacity in compact spaces, making them suitable for motorcycles, racing cars, and heavy-duty vehicles.

What is a Single Plate Clutch?

A Single Plate Clutch consists of one friction plate that engages the engine's power to the transmission, commonly used in motorcycles and cars for smoother and simpler operation. Your vehicle uses this type of clutch for efficient power transfer with less complexity and easier maintenance compared to multi-plate clutches. This clutch type offers reliable performance in everyday driving conditions where moderate power handling is sufficient.

What is a Multi Plate Clutch?

A Multi Plate Clutch consists of multiple friction plates stacked alternately with steel plates, increasing the contact surface area for enhanced torque transmission. It is commonly used in high-performance vehicles and motorcycles due to its ability to handle greater power and provide smoother engagement under heavy loads. The design enables efficient heat dissipation and compact size compared to single plate clutches, making it ideal for applications requiring rapid response and durability.

Construction Differences

Single plate clutches feature a single friction disc situated between the engine flywheel and pressure plate, offering a simpler and more compact construction ideal for standard vehicles. Multi plate clutches incorporate multiple friction discs stacked together, increasing surface area for better torque transmission in high-performance or heavy-duty applications. Your choice depends on the required durability, torque capacity, and space constraints in the vehicle's drivetrain system.

Working Principle: Single vs Multi Plate Clutch

Single plate clutches operate by engaging a single friction disc pressed between the flywheel and pressure plate, providing smooth power transmission ideal for lighter vehicles. Multi plate clutches utilize multiple friction discs stacked together, increasing the surface area for better torque handling and heat dissipation, making them suitable for high-performance or heavy-duty applications. Your choice depends on whether you prioritize simplicity and smooth operation or enhanced torque capacity and durability.

Friction Surface Comparison

Single plate clutches feature one friction surface, which provides a larger contact area for moderate torque transfer, enhancing smooth engagement in everyday vehicles. Multi plate clutches incorporate multiple friction surfaces stacked together, significantly increasing the total friction area and enabling higher torque capacity within a compact design. The increased friction surface in multi plate clutches results in better heat dissipation and improved performance in high-stress applications like racing or heavy machinery.

Heat Dissipation Capabilities

Single plate clutches provide moderate heat dissipation due to a single friction surface, making them suitable for applications with lower torque and heat generation. Multi plate clutches feature multiple friction surfaces that distribute heat more effectively, allowing for better performance under higher torque and continuous operation. Your choice between the two should depend on the heat dissipation demands of your vehicle or machinery to ensure optimal clutch efficiency and longevity.

Applications in Automotive Industry

Single plate clutches are predominantly used in passenger cars due to their compact design and efficient torque transmission suited for lighter loads and smoother gear shifts. Multi plate clutches find extensive application in high-performance vehicles, motorcycles, and heavy-duty trucks, where increased torque capacity and better heat dissipation are critical for managing higher engine power and frequent gear changes. Their ability to handle greater torque in limited space makes multi plate clutches ideal for sport cars and commercial vehicles with demanding performance requirements.

Advantages and Disadvantages

Single plate clutches offer simplicity, lightweight design, and cost-effectiveness, making them ideal for most passenger vehicles, but they tend to have lower torque capacity and faster wear under heavy loads. Multi plate clutches provide higher torque transmission, better heat dissipation, and are preferred in high-performance or racing applications, yet they are more complex, heavier, and require more maintenance. Choosing between them depends on the vehicle's power demands, usage conditions, and maintenance capabilities.

Which Clutch is Best for You?

A single plate clutch is ideal for everyday driving due to its simplicity, lower cost, and ease of maintenance, offering smooth engagement for lighter vehicles. Multi plate clutches, featuring multiple friction discs, provide higher torque capacity and better performance, making them suitable for high-performance or heavy-duty applications. Your choice depends on driving conditions and vehicle requirements, with single plate clutches best for standard use and multi plate clutches excelling in demanding environments.

Single Plate Clutch vs Multi Plate Clutch Infographic

libmatt.com

libmatt.com