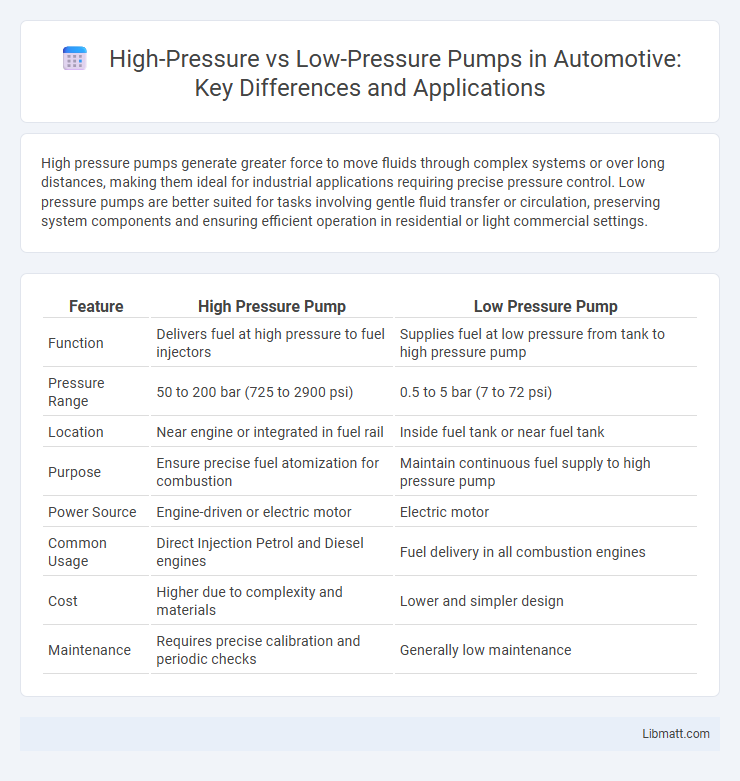

High pressure pumps generate greater force to move fluids through complex systems or over long distances, making them ideal for industrial applications requiring precise pressure control. Low pressure pumps are better suited for tasks involving gentle fluid transfer or circulation, preserving system components and ensuring efficient operation in residential or light commercial settings.

Table of Comparison

| Feature | High Pressure Pump | Low Pressure Pump |

|---|---|---|

| Function | Delivers fuel at high pressure to fuel injectors | Supplies fuel at low pressure from tank to high pressure pump |

| Pressure Range | 50 to 200 bar (725 to 2900 psi) | 0.5 to 5 bar (7 to 72 psi) |

| Location | Near engine or integrated in fuel rail | Inside fuel tank or near fuel tank |

| Purpose | Ensure precise fuel atomization for combustion | Maintain continuous fuel supply to high pressure pump |

| Power Source | Engine-driven or electric motor | Electric motor |

| Common Usage | Direct Injection Petrol and Diesel engines | Fuel delivery in all combustion engines |

| Cost | Higher due to complexity and materials | Lower and simpler design |

| Maintenance | Requires precise calibration and periodic checks | Generally low maintenance |

Introduction to High and Low Pressure Pumps

High pressure pumps generate fluid pressure typically above 1000 psi, making them ideal for applications requiring intense force such as hydraulic machinery, water jet cutting, and industrial cleaning. Low pressure pumps operate at pressures below 1000 psi and are commonly used for general fluid transfer, circulation, and irrigation systems. Understanding the pressure range and application requirements is essential for selecting the appropriate pump type to ensure efficiency and longevity.

Key Differences Between High and Low Pressure Pumps

High pressure pumps generate significantly greater force, often exceeding 1,000 psi, making them ideal for applications requiring intense fluid delivery like industrial cleaning or hydraulic systems. Low pressure pumps operate below 100 psi, providing steady, gentle flow suitable for tasks such as water circulation, irrigation, and cooling systems. Your choice between high and low pressure pumps depends on the pressure requirements, flow rate, and specific system demands to ensure optimal performance and safety.

Applications of High Pressure Pumps

High pressure pumps are essential in industries requiring intense fluid force, such as water jet cutting, reverse osmosis, and hydraulic fracturing. These pumps deliver fluid at pressures exceeding 1,000 psi, making them ideal for cleaning surfaces, firefighting systems, and chemical injection processes. Your operational efficiency improves significantly when using high pressure pumps for applications demanding precise and powerful fluid delivery.

Applications of Low Pressure Pumps

Low pressure pumps are commonly used in applications requiring the gentle movement of fluids, such as irrigation systems, water circulation in aquariums, and fuel transfer in small engines. They excel in situations where maintaining a steady flow without excessive force is critical, including HVAC systems for water circulation and industrial processes involving chemicals with low viscosity. These pumps provide energy-efficient operation and lower wear, making them ideal for continuous or intermittent use in residential, agricultural, and light industrial environments.

Performance and Efficiency Comparison

High pressure pumps deliver superior performance by generating greater force to move fluids through systems requiring high resistance, resulting in higher energy consumption compared to low pressure pumps. Low pressure pumps provide enhanced efficiency in applications with minimal resistance, reducing operational costs and energy use while maintaining adequate flow rates. You should select a pump based on the specific pressure requirements and efficiency goals of your system to optimize performance and minimize energy expenditure.

Cost Considerations: High vs Low Pressure Pumps

High pressure pumps typically have higher upfront costs due to robust materials and engineering required to handle intense pressures, while low pressure pumps are generally more affordable and simpler in design. Maintenance expenses for high pressure pumps can also be greater because of frequent part replacements and specialized servicing needs, whereas low pressure pumps benefit from lower upkeep costs and longer service intervals. Choosing between them depends on application pressure requirements and budget constraints, where low pressure pumps are cost-effective for moderate demands and high pressure pumps justify investment for rigorous industrial use.

Maintenance and Durability Factors

High pressure pumps require more frequent maintenance due to their complex seals and tighter tolerances, which are necessary to handle increased operating pressures. Low pressure pumps typically have simpler designs, resulting in less wear and longer durability under standard operating conditions. Your choice between high and low pressure pumps should consider maintenance schedules and expected lifespan based on the specific demands of your application.

Safety Aspects in High and Low Pressure Systems

High pressure pumps require rigorous safety protocols due to the increased risk of leaks, bursts, and equipment failure under intense pressure, necessitating robust materials and regular maintenance. Low pressure pumps present lower risk levels but still demand proper safeguards to prevent overheating, cavitation, and contamination. Ensuring your system adheres to appropriate safety standards minimizes hazards and prolongs pump lifespan in both high and low pressure environments.

Choosing the Right Pump for Your Needs

Selecting the right pump depends on the specific pressure requirements and application. High pressure pumps deliver powerful force for tasks like industrial cleaning or hydraulic systems, while low pressure pumps are ideal for gentle fluid circulation and low-resistance systems. Understanding your system's flow rate, pressure demands, and energy efficiency needs ensures optimal performance and longevity of your pump.

Conclusion: Which Pump is Best for Your Application?

High pressure pumps deliver superior performance in applications requiring intense force for fluid movement, such as industrial cleaning, hydraulic systems, and water jet cutting. Low pressure pumps are ideal for tasks involving gentle fluid transfer, such as irrigation, HVAC circulation, and aquarium systems, offering energy efficiency and reduced wear. Selecting the best pump depends on the specific pressure requirements, flow rate, and durability needed for your application's operational environment.

High Pressure Pump vs Low Pressure Pump Infographic

libmatt.com

libmatt.com