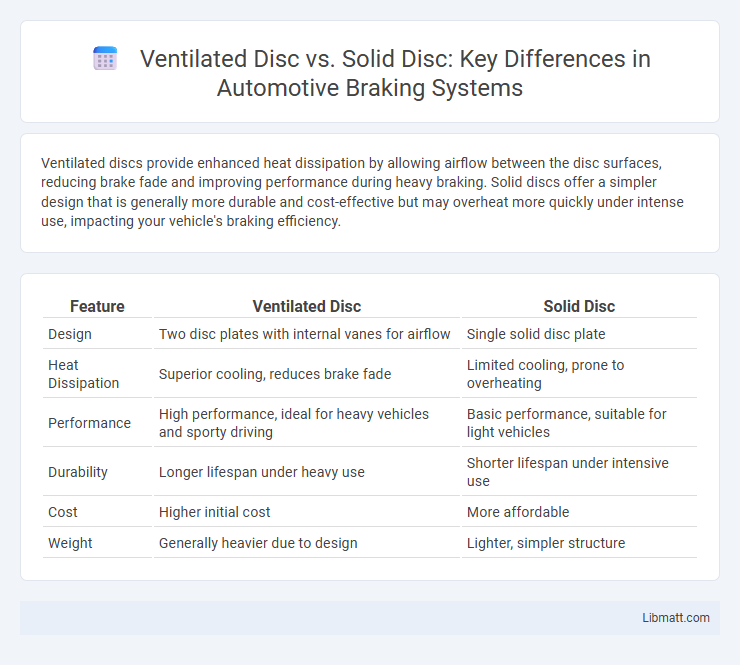

Ventilated discs provide enhanced heat dissipation by allowing airflow between the disc surfaces, reducing brake fade and improving performance during heavy braking. Solid discs offer a simpler design that is generally more durable and cost-effective but may overheat more quickly under intense use, impacting your vehicle's braking efficiency.

Table of Comparison

| Feature | Ventilated Disc | Solid Disc |

|---|---|---|

| Design | Two disc plates with internal vanes for airflow | Single solid disc plate |

| Heat Dissipation | Superior cooling, reduces brake fade | Limited cooling, prone to overheating |

| Performance | High performance, ideal for heavy vehicles and sporty driving | Basic performance, suitable for light vehicles |

| Durability | Longer lifespan under heavy use | Shorter lifespan under intensive use |

| Cost | Higher initial cost | More affordable |

| Weight | Generally heavier due to design | Lighter, simpler structure |

Introduction to Brake Disc Types

Ventilated discs feature dual layers with internal channels that enhance heat dissipation, reducing brake fade during heavy use. Solid discs are a single, solid piece of metal offering simplicity and cost-effectiveness but with less efficient heat management. Choosing between ventilated and solid discs depends on performance needs, vehicle type, and driving conditions.

What is a Ventilated Disc?

A ventilated disc is a type of brake rotor designed with internal vanes or channels between two disc faces to enhance heat dissipation during braking. This structure improves cooling efficiency, reducing the risk of brake fade and extending the durability of braking components compared to solid discs. Ventilated discs are commonly used in high-performance and heavy-duty vehicles to maintain consistent braking performance under demanding conditions.

What is a Solid Disc?

A solid disc is a type of brake rotor characterized by a single, continuous metal plate without internal channels or vents, providing a straightforward design for consistent braking performance. Solid discs are commonly used in rear braking systems or in vehicles with lower braking demands due to their simplicity and cost-effectiveness. Compared to ventilated discs, solid discs have limited heat dissipation capabilities, which can lead to higher temperatures and potential brake fade during extended or heavy braking.

Key Differences Between Ventilated and Solid Discs

Ventilated discs feature internal channels that allow air to pass through, enhancing heat dissipation and reducing brake fade during heavy use. Solid discs, being a single solid piece of metal, are simpler in design and typically more cost-effective but can overheat more quickly under intense braking conditions. Understanding these key differences helps you choose the right brake disc for performance and driving demands.

Ventilated Disc: Advantages and Disadvantages

Ventilated disc brakes offer superior heat dissipation due to their dual-layer design with internal vanes, reducing the risk of brake fade during prolonged or heavy braking, making them ideal for high-performance and heavy vehicles. Their enhanced cooling capability improves overall braking efficiency and safety, especially in demanding conditions, but they tend to be heavier and more complex to manufacture compared to solid discs. While ventilated discs provide better performance longevity, they may incur higher maintenance costs and are less suitable for lighter, everyday vehicles where cost and simplicity are prioritized.

Solid Disc: Pros and Cons

Solid disc brakes offer consistent performance and are typically more durable, making them ideal for everyday driving and light-duty vehicles. They generate less noise and are easier to manufacture, resulting in lower costs, but they dissipate heat less efficiently, which can lead to brake fade under heavy or prolonged use. Your choice should consider the balance between cost-effectiveness and the need for superior heat management in braking performance.

Performance Comparison: Ventilated vs Solid Discs

Ventilated discs offer superior heat dissipation compared to solid discs, reducing brake fade during high-performance or prolonged braking. The airflow created by the ventilation channels helps maintain consistent braking efficiency and prolongs rotor lifespan. Solid discs, while simpler and more cost-effective, are better suited for low-stress applications with less intense heat buildup.

Suitability for Different Vehicle Types

Ventilated discs are ideal for high-performance and heavy vehicles such as sports cars, trucks, and SUVs due to their superior heat dissipation, preventing brake fade during intense use. Solid discs are better suited for lighter, everyday passenger vehicles where braking demands are moderate and cost-effectiveness is important. Choosing the appropriate disc type enhances braking efficiency and safety based on the vehicle's weight and driving conditions.

Maintenance and Longevity Considerations

Ventilated discs offer improved heat dissipation, reducing the risk of brake fade and extending overall component lifespan compared to solid discs. Your maintenance efforts can be less frequent with ventilated discs, as they better manage thermal stress and wear. Solid discs, while simpler and often less costly, may require more regular inspection and replacement due to faster heat buildup and associated wear.

Choosing the Right Disc for Your Driving Needs

Ventilated discs offer superior heat dissipation and improved braking performance, making them ideal for aggressive driving or heavy-duty use, while solid discs provide reliable stopping power for everyday city and light-duty driving. Choosing the right disc depends on your driving habits, vehicle type, and performance demands to ensure optimal safety and longevity. Your vehicle's braking system will benefit from the enhanced thermal management of ventilated discs in high-stress conditions, whereas solid discs are cost-effective and sufficient for standard driving.

Ventilated Disc vs Solid Disc Infographic

libmatt.com

libmatt.com