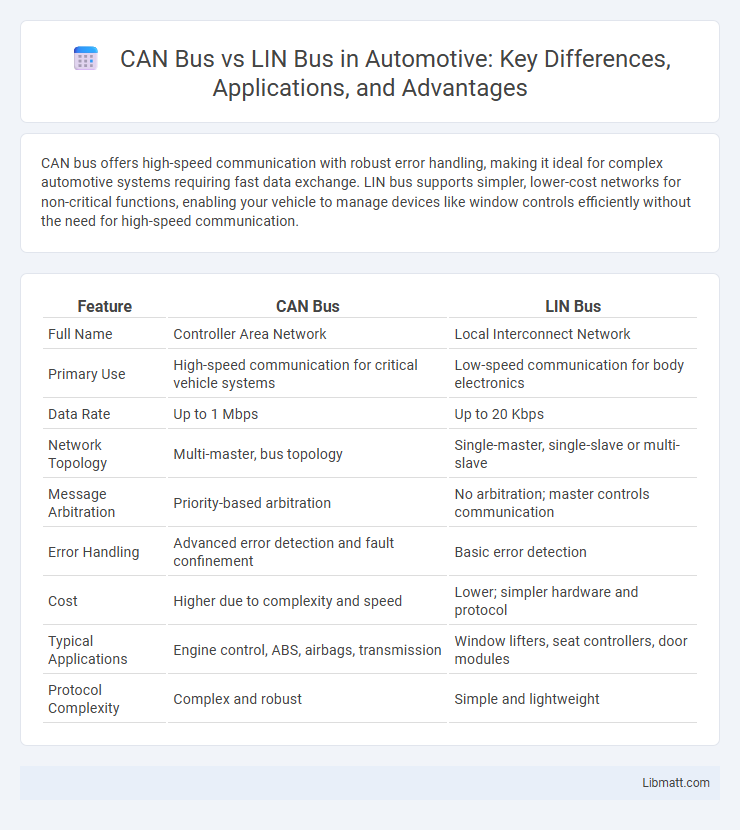

CAN bus offers high-speed communication with robust error handling, making it ideal for complex automotive systems requiring fast data exchange. LIN bus supports simpler, lower-cost networks for non-critical functions, enabling your vehicle to manage devices like window controls efficiently without the need for high-speed communication.

Table of Comparison

| Feature | CAN Bus | LIN Bus |

|---|---|---|

| Full Name | Controller Area Network | Local Interconnect Network |

| Primary Use | High-speed communication for critical vehicle systems | Low-speed communication for body electronics |

| Data Rate | Up to 1 Mbps | Up to 20 Kbps |

| Network Topology | Multi-master, bus topology | Single-master, single-slave or multi-slave |

| Message Arbitration | Priority-based arbitration | No arbitration; master controls communication |

| Error Handling | Advanced error detection and fault confinement | Basic error detection |

| Cost | Higher due to complexity and speed | Lower; simpler hardware and protocol |

| Typical Applications | Engine control, ABS, airbags, transmission | Window lifters, seat controllers, door modules |

| Protocol Complexity | Complex and robust | Simple and lightweight |

Introduction to CAN Bus and LIN Bus

CAN bus (Controller Area Network) is a robust vehicle bus standard designed for high-speed data communication between microcontrollers and devices in automotive and industrial applications. LIN bus (Local Interconnect Network) is a lower-cost, slower communication protocol primarily used for simpler, less critical sub-systems such as door modules and climate control. CAN supports multi-master configuration with error detection and data integrity, while LIN is a single-master, multiple-slave network optimized for cost efficiency and simplicity.

Overview of CAN Bus Technology

CAN bus technology, developed by Bosch in the 1980s, is a robust vehicle bus standard designed for efficient communication between microcontrollers and devices without a host computer. It supports high-speed data transfer rates up to 1 Mbps and uses a multi-master, message-oriented protocol that ensures reliable error detection and fault confinement. CAN bus is widely implemented in automotive systems for engine control units, airbags, and ABS due to its real-time capabilities and noise immunity.

Overview of LIN Bus Technology

LIN (Local Interconnect Network) bus technology is a low-cost, single-wire communication protocol designed primarily for automotive applications to manage simple and cost-sensitive subsystems like door modules, seat controls, and climate control. LIN operates at speeds up to 20 kbps and uses a master-slave architecture, making it ideal for non-critical communication tasks that do not require the higher bandwidth and robustness of CAN bus systems. Its simplicity and reduced wiring complexity enable efficient integration with CAN bus networks, enhancing overall vehicle network flexibility and cost-effectiveness.

Key Differences Between CAN and LIN Bus

CAN bus supports higher data rates up to 1 Mbps, whereas LIN bus operates at a maximum of 20 Kbps, making CAN suitable for complex and time-critical applications. CAN provides multi-master communication with error detection and fault confinement features, while LIN uses a single master and multiple slaves with simpler error handling. The CAN protocol is more robust and ideal for automotive networks requiring real-time data exchange, whereas LIN offers a cost-effective solution for lower-speed sensor and actuator communication.

Data Transmission Speed Comparison

CAN bus typically offers data transmission speeds up to 1 Mbps, making it suitable for real-time automotive applications requiring fast communication. LIN bus, in contrast, supports speeds up to 20 Kbps, sufficient for simpler, low-speed control tasks within vehicle subsystems. Your choice between CAN and LIN buses depends on the required data speed and system complexity in your automotive network.

Network Topology and Scalability

CAN bus uses a multi-master, broadcast network topology allowing high scalability with numerous nodes interconnected via a twisted pair cable, ideal for complex automotive and industrial systems. LIN bus employs a single-master, multi-slave daisy-chain topology with limited data rate and node count, optimized for simple, low-cost sub-networks in vehicle body electronics. CAN networks support up to 1 Mbps data rate and 110 nodes, whereas LIN is limited to 20 Kbps and 16 nodes, highlighting CAN's superiority in scalability and robustness.

Cost Efficiency: CAN Bus vs LIN Bus

LIN bus offers greater cost efficiency for simple, low-speed automotive networks due to its reduced hardware complexity and lower implementation expenses compared to CAN bus. CAN bus, while more expensive, provides higher data rates, robustness, and fault tolerance, justifying its cost in critical safety and control applications. Choosing between CAN and LIN buses depends on balancing budget constraints with the required communication performance and network complexity.

Typical Applications in Automotive Systems

CAN bus is widely used in automotive systems for powertrain control, body electronics, and safety features due to its high-speed data transmission (up to 1 Mbps) and robust error handling. LIN bus serves as a cost-effective solution for lower-speed applications such as window controls, seat adjustments, and interior lighting, operating at speeds up to 20 Kbps. The integration of both buses optimizes vehicle network architecture by balancing performance and cost across various electronic control units (ECUs).

Advantages and Disadvantages of CAN and LIN Bus

CAN bus offers high data transfer rates up to 1 Mbps and robust error detection, making it ideal for complex automotive networks requiring real-time communication. LIN bus, with lower speeds around 20 Kbps and a simpler protocol, serves well for cost-effective applications like window controls and seat adjustments but lacks the advanced fault tolerance of CAN. Your choice depends on the need for speed, reliability, and system complexity; CAN provides superior performance for critical systems, while LIN is advantageous for simpler, less demanding tasks.

Choosing the Right Bus for Your Application

Selecting between CAN bus and LIN bus depends on application complexity and required data speed; CAN bus supports higher data rates up to 1 Mbps and robust error handling, ideal for critical automotive systems and industrial automation. LIN bus, with speeds up to 20 Kbps and a simpler, cost-effective design, suits low-speed, less complex networks like door modules and sensor communication. Evaluating factors such as network length, node count, and fault tolerance ensures optimal performance and cost-efficiency.

CAN bus vs LIN bus Infographic

libmatt.com

libmatt.com