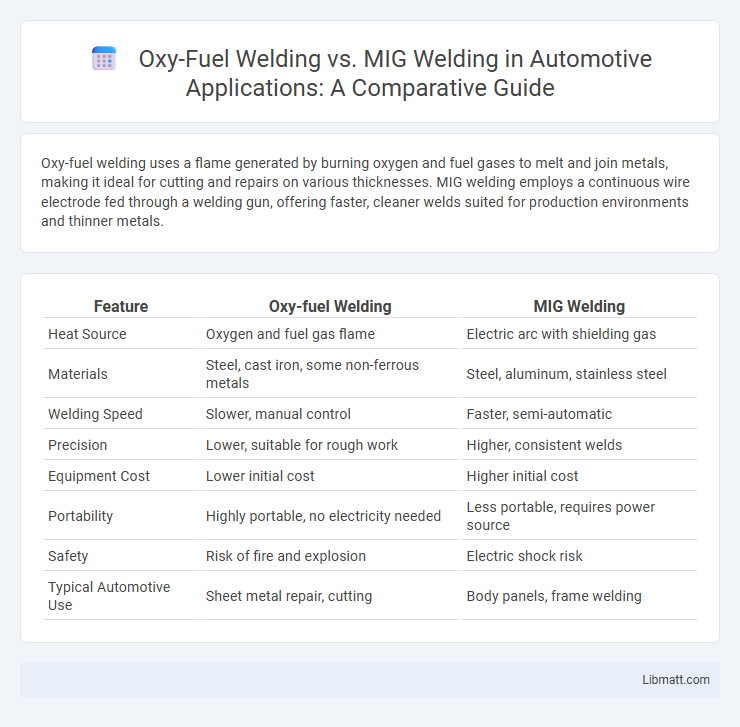

Oxy-fuel welding uses a flame generated by burning oxygen and fuel gases to melt and join metals, making it ideal for cutting and repairs on various thicknesses. MIG welding employs a continuous wire electrode fed through a welding gun, offering faster, cleaner welds suited for production environments and thinner metals.

Table of Comparison

| Feature | Oxy-fuel Welding | MIG Welding |

|---|---|---|

| Heat Source | Oxygen and fuel gas flame | Electric arc with shielding gas |

| Materials | Steel, cast iron, some non-ferrous metals | Steel, aluminum, stainless steel |

| Welding Speed | Slower, manual control | Faster, semi-automatic |

| Precision | Lower, suitable for rough work | Higher, consistent welds |

| Equipment Cost | Lower initial cost | Higher initial cost |

| Portability | Highly portable, no electricity needed | Less portable, requires power source |

| Safety | Risk of fire and explosion | Electric shock risk |

| Typical Automotive Use | Sheet metal repair, cutting | Body panels, frame welding |

Introduction to Oxy-Fuel and MIG Welding

Oxy-fuel welding utilizes a flame produced by burning oxygen and a fuel gas to melt metals for joining, offering precise control for cutting and welding. MIG welding, or Metal Inert Gas welding, employs a continuous wire electrode and a shielding gas to create strong, clean welds with high efficiency, especially suitable for thin to medium thickness materials. Both methods cater to different fabrication needs, with oxy-fuel favored for versatility in fieldwork and MIG preferred for speed and automation in manufacturing environments.

How Oxy-Fuel Welding Works

Oxy-fuel welding operates by mixing oxygen and a fuel gas, such as acetylene, to produce a high-temperature flame capable of melting metal surfaces for joining. This process relies on precise control of gas flow through regulators and a torch, enabling you to shape and weld various metals with heat reaching up to 3,500degC (6,332degF). Unlike MIG welding, which uses an electric arc and wire feed, oxy-fuel welding offers greater portability and flexibility for cutting and welding tasks in diverse environments.

How MIG Welding Operates

MIG welding operates by feeding a continuous solid wire electrode through a welding gun while simultaneously supplying a shielding gas, typically argon or a mix of argon and carbon dioxide, to protect the weld pool from atmospheric contamination. The electric arc formed between the wire electrode and the workpiece melts the wire and base metal, creating a strong fusion. This process is known for its high welding speed, ease of automation, and suitability for welding thin to thick materials with minimal slag formation.

Equipment and Setup Requirements

Oxy-fuel welding requires a torch, oxygen and fuel gas cylinders, regulators, and hoses, making the setup bulky and gas-dependent. MIG welding involves a power source, wire feed system, welding gun, and shielding gas tank, offering a more automated and compact configuration. Your choice depends on workspace constraints and the desired efficiency in equipment setup and operation.

Materials Compatible with Each Method

Oxy-fuel welding is compatible with a wide range of ferrous and non-ferrous metals including steel, cast iron, copper, and aluminum, making it versatile for various fabrication tasks. MIG welding excels with steel, stainless steel, and aluminum, providing faster welding speeds and cleaner welds, especially in automotive and industrial applications. The choice between these methods depends largely on the material thickness, type, and the desired weld quality for the specific project.

Strength and Quality of Welds

Oxy-fuel welding produces strong welds with good penetration, ideal for thicker metals but may require more skill to achieve consistent results. MIG welding offers superior weld quality with cleaner, more uniform beads and better control over heat input, resulting in stronger joints with less distortion. The choice depends on the material thickness and application, with MIG welding favored for precision and repeatability in industrial settings.

Speed and Efficiency Comparison

Oxy-fuel welding operates at slower speeds due to the manual control of gas flow and flame adjustment, making it less efficient for high-volume production. MIG welding offers faster welding speeds and higher deposition rates by using a continuous wire feed and electric arc, significantly improving overall efficiency in industrial applications. Your choice depends on the project's speed requirements and the need for precision versus rapid throughput.

Safety Considerations for Both Techniques

Oxy-fuel welding involves open flames and combustible gases, requiring strict ventilation and protective gear to prevent burns and inhalation hazards. MIG welding produces intense UV radiation and fumes, making appropriate eye protection, gloves, and respiratory equipment essential to avoid arc flash and respiratory issues. Ensuring your workspace is well-ventilated and equipped with safety monitors significantly reduces the risks associated with both welding methods.

Cost Analysis: Oxy-Fuel vs MIG Welding

Oxy-fuel welding equipment typically costs less upfront, with basic setups priced around $100 to $300, while MIG welding systems range from $500 to over $2,000 depending on features and power capacity. Operating costs for oxy-fuel welding can be higher due to continuous consumption of oxygen and fuel gases, whereas MIG welding uses electricity and consumable wire, which can be more cost-efficient for high-volume or automated jobs. Maintenance and consumables also impact expenses, as oxy-fuel torches require regular cylinder refills and replacements, while MIG welders involve wire spools and occasional contact tip changes.

Choosing the Right Welding Method for Your Project

Oxy-fuel welding excels in cutting and torch brazing with excellent control over heat input, making it ideal for thinner metals and repair work. MIG welding provides faster deposition rates, superior weld strength, and ease of automation, suitable for thicker materials and production environments. Selecting the right method depends on factors such as material thickness, project scale, desired weld quality, and cost efficiency.

Oxy-fuel welding vs MIG welding Infographic

libmatt.com

libmatt.com