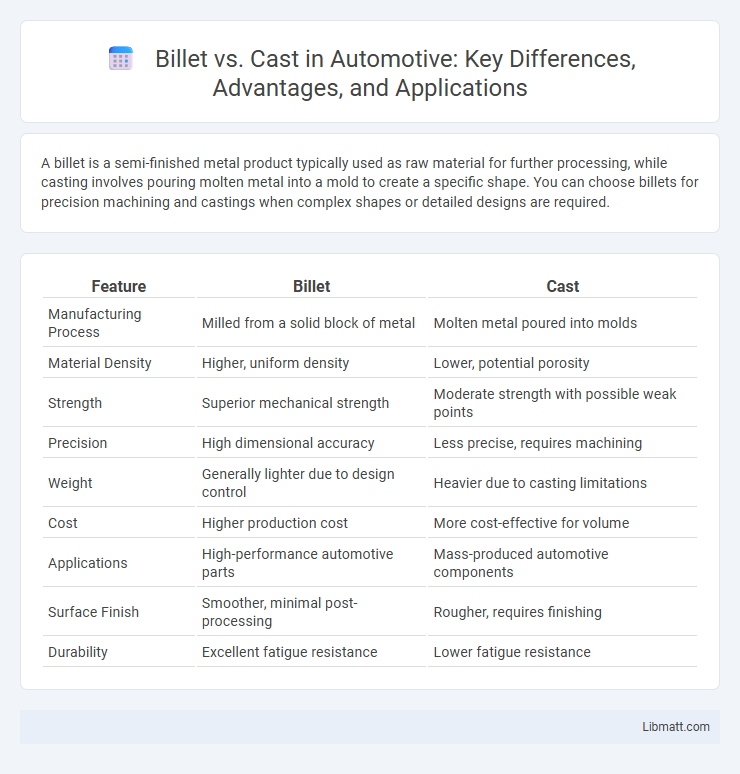

A billet is a semi-finished metal product typically used as raw material for further processing, while casting involves pouring molten metal into a mold to create a specific shape. You can choose billets for precision machining and castings when complex shapes or detailed designs are required.

Table of Comparison

| Feature | Billet | Cast |

|---|---|---|

| Manufacturing Process | Milled from a solid block of metal | Molten metal poured into molds |

| Material Density | Higher, uniform density | Lower, potential porosity |

| Strength | Superior mechanical strength | Moderate strength with possible weak points |

| Precision | High dimensional accuracy | Less precise, requires machining |

| Weight | Generally lighter due to design control | Heavier due to casting limitations |

| Cost | Higher production cost | More cost-effective for volume |

| Applications | High-performance automotive parts | Mass-produced automotive components |

| Surface Finish | Smoother, minimal post-processing | Rougher, requires finishing |

| Durability | Excellent fatigue resistance | Lower fatigue resistance |

Understanding Billet and Cast Manufacturing

Billet manufacturing involves machining parts from a solid block of metal, offering superior strength and precision due to the uniform grain structure and minimal internal defects. Cast manufacturing shapes molten metal into molds, providing cost-effective production for complex geometries but potentially exhibiting less structural integrity and surface finish than billet parts. Understanding these differences is crucial for selecting the optimal fabrication method based on mechanical properties, production volume, and design complexity.

Key Differences Between Billet and Cast Processes

Billet manufacturing involves shaping metal from a solid block through machining, resulting in superior strength and precision, while casting melts metal to pour into molds, allowing complex shapes but with potential porosity and lower structural integrity. The billet process offers enhanced durability and tighter tolerances due to uniform grain structure, contrasting with casting's cost-effectiveness for intricate designs and large-scale production. Understanding these differences helps you choose the optimal method based on performance requirements and budget constraints.

Material Properties: Billet vs. Cast

Billet materials exhibit superior mechanical properties such as higher tensile strength, better fatigue resistance, and improved grain structure compared to cast materials. The controlled forging process of billets results in a denser, more uniform microstructure, enhancing durability and performance under stress. Cast materials often contain porosity and inclusions, which can compromise structural integrity and reduce overall material reliability.

Strength and Durability Comparison

Billet metals, machined from solid blocks of high-grade aluminum or steel, exhibit superior strength and durability due to their dense and uniform grain structure. Cast metals, formed by pouring molten metal into molds, often contain microscopic porosity and imperfections, which can reduce overall mechanical strength and increase susceptibility to cracking. The precision and consistency of billet manufacturing result in components with enhanced fatigue resistance and longer lifespan in demanding applications.

Cost Implications: Billet vs. Cast

Billet components typically incur higher production costs due to material waste and extensive machining processes, whereas cast parts offer cost efficiency with near-net shape manufacturing and lower material waste. Castings are ideal for large production runs, reducing per-unit cost, while billet is preferred for smaller runs or custom parts where strength and precision justify increased expenses. Understanding these cost implications helps manufacturers balance budget constraints with performance requirements.

Applications and Use Cases

Billet materials, known for their high strength and precision, are commonly used in aerospace, automotive, and high-performance engineering applications requiring superior mechanical properties and tight tolerances. Cast components excel in complex geometries and are prevalent in industries such as construction, heavy machinery, and automotive engine blocks where cost efficiency and design flexibility are prioritized. The choice between billet and cast parts depends on factors like performance requirements, manufacturing volume, and material properties critical to applications such as structural components, engine parts, and custom prototypes.

Performance in Automotive and Aerospace Industries

Billet materials offer superior strength and precision, making them ideal for high-performance automotive and aerospace components that demand durability and exact tolerances. Cast metals, although more cost-effective and versatile for complex shapes, can exhibit less uniformity and lower mechanical properties compared to billet, impacting overall performance. Your choice between billet and cast will directly affect the reliability, weight, and efficiency of critical parts in engines, airframes, and structural assemblies.

Pros and Cons of Billet Parts

Billet parts offer superior strength, precision, and customization compared to cast components, making them ideal for high-performance applications. Their manufacturing process results in fewer defects and enhanced durability, but they come at a higher cost and longer production time. You benefit from billet parts when prioritizing quality and reliability over budget constraints.

Pros and Cons of Cast Parts

Cast parts offer complex shapes and intricate details difficult to achieve with billet machining, improving design flexibility and reducing production costs for large volumes. However, cast components typically have lower mechanical strength and higher porosity compared to billet parts, which can lead to increased susceptibility to cracks and defects under stress. The trade-off between cost efficiency and material integrity makes cast parts ideal for applications prioritizing detailed geometry over maximum durability.

Choosing the Best Manufacturing Method

Billet manufacturing involves machining parts from a solid block of metal, offering superior strength, precision, and customization compared to casting, which pours molten metal into molds for complex shapes at lower costs. Choosing the best method depends on factors like required durability, production volume, and budget constraints; billet is ideal for high-performance applications needing tight tolerances, while cast components suit large-scale, cost-sensitive projects. Understanding material properties and desired structural integrity helps optimize manufacturing efficiency and product lifespan.

billet vs cast Infographic

libmatt.com

libmatt.com