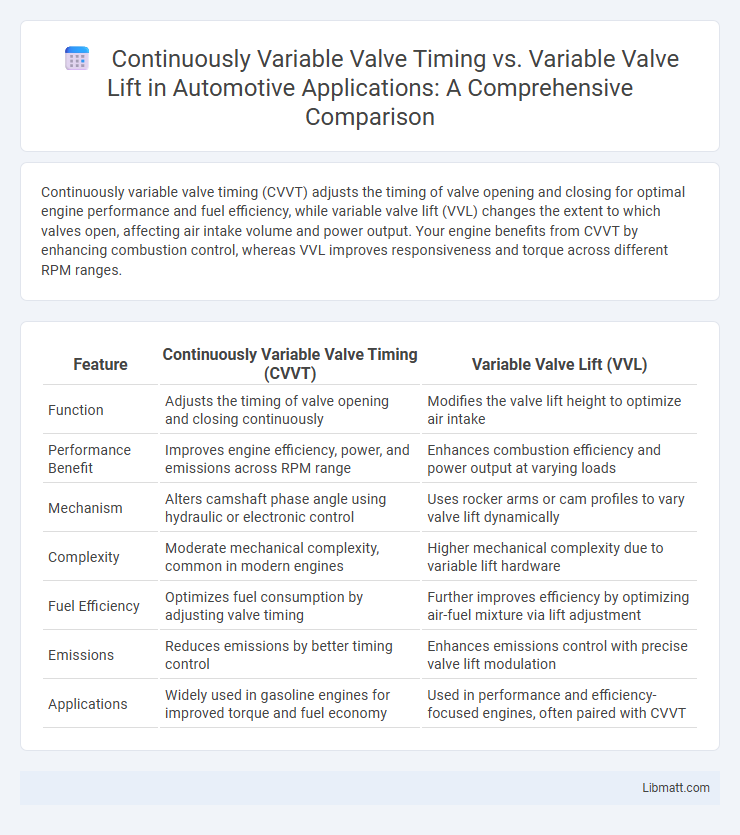

Continuously variable valve timing (CVVT) adjusts the timing of valve opening and closing for optimal engine performance and fuel efficiency, while variable valve lift (VVL) changes the extent to which valves open, affecting air intake volume and power output. Your engine benefits from CVVT by enhancing combustion control, whereas VVL improves responsiveness and torque across different RPM ranges.

Table of Comparison

| Feature | Continuously Variable Valve Timing (CVVT) | Variable Valve Lift (VVL) |

|---|---|---|

| Function | Adjusts the timing of valve opening and closing continuously | Modifies the valve lift height to optimize air intake |

| Performance Benefit | Improves engine efficiency, power, and emissions across RPM range | Enhances combustion efficiency and power output at varying loads |

| Mechanism | Alters camshaft phase angle using hydraulic or electronic control | Uses rocker arms or cam profiles to vary valve lift dynamically |

| Complexity | Moderate mechanical complexity, common in modern engines | Higher mechanical complexity due to variable lift hardware |

| Fuel Efficiency | Optimizes fuel consumption by adjusting valve timing | Further improves efficiency by optimizing air-fuel mixture via lift adjustment |

| Emissions | Reduces emissions by better timing control | Enhances emissions control with precise valve lift modulation |

| Applications | Widely used in gasoline engines for improved torque and fuel economy | Used in performance and efficiency-focused engines, often paired with CVVT |

Introduction to Variable Valve Technologies

Variable valve timing (VVT) adjusts the timing of valve opening and closing to optimize engine performance, fuel efficiency, and emissions across different RPM ranges. Variable valve lift (VVL) changes the extent to which valves open, enhancing airflow and combustion control for improved power and efficiency. Your engine's adaptability benefits significantly from combining these technologies, allowing precise control over valve operation to meet performance and environmental demands.

Understanding Continuously Variable Valve Timing (CVVT)

Continuously Variable Valve Timing (CVVT) adjusts the timing of valve opening and closing dynamically to optimize engine performance, fuel efficiency, and emissions. Unlike Variable Valve Lift systems that alter the valve lift magnitude, CVVT fine-tunes the valve timing throughout the engine's operating range for smoother power delivery and improved torque. Your vehicle's engine benefits from CVVT by maintaining optimal combustion conditions, ensuring better responsiveness and reduced fuel consumption.

Exploring Variable Valve Lift (VVL) Systems

Variable Valve Lift (VVL) systems enhance engine efficiency by dynamically adjusting the lift of the intake or exhaust valves, optimizing airflow and combustion across different engine speeds. Unlike Continuously Variable Valve Timing (CVVT), which primarily modifies valve opening and closing timing, VVL controls valve lift height to improve power output and fuel economy. Understanding VVL technology can help you appreciate how manufacturers achieve better performance and lower emissions through advanced valve actuation.

Key Differences Between CVVT and VVL

Continuously Variable Valve Timing (CVVT) adjusts the timing of the intake and exhaust valves to optimize engine performance and fuel efficiency across different RPM ranges, while Variable Valve Lift (VVL) changes the valve lift height to enhance engine breathing and power output. CVVT primarily focuses on the phase angle of valve operation for better torque and emissions control, whereas VVL modifies the valve open position to increase airflow and combustion efficiency. Together, these technologies improve overall engine responsiveness but operate through fundamentally different mechanisms: timing alteration for CVVT versus mechanical lift adjustment for VVL.

Impact on Engine Performance and Efficiency

Continuously variable valve timing (CVVT) adjusts the timing of valve opening and closing to optimize engine performance across different RPM ranges, enhancing fuel efficiency and reducing emissions. Variable valve lift (VVL) changes the valve lift height to improve airflow and combustion efficiency, resulting in increased power output and torque at varying engine speeds. Combining CVVT and VVL technologies can significantly boost engine responsiveness, fuel economy, and overall efficiency by precisely controlling valve operation based on driving conditions.

Fuel Economy Comparison: CVVT vs VVL

Continuously variable valve timing (CVVT) improves fuel economy by optimizing the timing of valve opening and closing based on engine load and speed, resulting in more efficient combustion and reduced fuel consumption. Variable valve lift (VVL) enhances fuel efficiency by adjusting the valve lift height to control airflow, which improves combustion at different engine speeds and reduces pumping losses. Your choice between CVVT and VVL systems will influence fuel economy depending on driving conditions, with CVVT excelling in smooth efficiency gains across a broad RPM range and VVL offering targeted improvements during specific engine loads.

Emissions and Environmental Benefits

Continuously variable valve timing (CVVT) enhances engine efficiency by optimizing valve opening and closing, which reduces fuel consumption and lowers harmful emissions such as NOx and CO2. Variable valve lift (VVL) adjusts the valve lift height for improved air intake control, leading to cleaner combustion and decreased unburned hydrocarbons in exhaust gases. Both technologies contribute to meeting stringent environmental regulations by minimizing pollutant output and improving overall engine performance.

Reliability and Maintenance Considerations

Continuously variable valve timing (CVVT) systems are generally more reliable due to fewer moving parts and simpler hydraulic actuation, resulting in lower maintenance requirements over time. Variable valve lift (VVL) systems, which involve complex mechanical components such as cams and lifters, can be more prone to wear and require more frequent inspections and potential adjustments. The simpler design of CVVT often translates to enhanced durability and reduced risk of failure compared to the intricate mechanisms of VVL systems.

Automotive Applications and Popular Models

Continuously variable valve timing (CVVT) enhances engine efficiency and performance by adjusting the valve opening timing dynamically, commonly found in models like the Toyota Camry and Honda Accord. Variable valve lift (VVL) improves power and fuel economy by altering the valve lift amount based on engine speed, popular in vehicles such as the BMW M Series and Nissan VQ engines. Your choice between CVVT and VVL depends on desired driving characteristics and fuel efficiency priorities.

Future Trends in Valve Control Technologies

Future trends in valve control technologies emphasize the integration of Continuously Variable Valve Timing (CVVT) with advanced Variable Valve Lift (VVL) systems to optimize engine efficiency and emissions control. Innovations aim to enhance real-time adaptability, allowing precise modulation of valve timing and lift based on driving conditions, which improves fuel economy and power output. Emerging developments also include the adoption of electro-hydraulic and electromagnetic actuators to replace traditional cam-driven mechanisms, facilitating faster response and greater flexibility in valve operation.

Continuously variable valve timing vs Variable valve lift Infographic

libmatt.com

libmatt.com