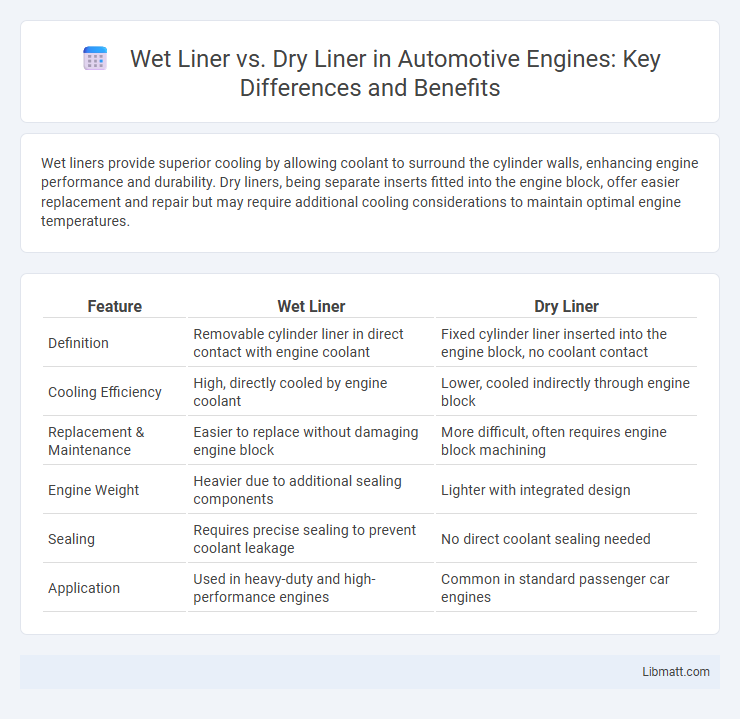

Wet liners provide superior cooling by allowing coolant to surround the cylinder walls, enhancing engine performance and durability. Dry liners, being separate inserts fitted into the engine block, offer easier replacement and repair but may require additional cooling considerations to maintain optimal engine temperatures.

Table of Comparison

| Feature | Wet Liner | Dry Liner |

|---|---|---|

| Definition | Removable cylinder liner in direct contact with engine coolant | Fixed cylinder liner inserted into the engine block, no coolant contact |

| Cooling Efficiency | High, directly cooled by engine coolant | Lower, cooled indirectly through engine block |

| Replacement & Maintenance | Easier to replace without damaging engine block | More difficult, often requires engine block machining |

| Engine Weight | Heavier due to additional sealing components | Lighter with integrated design |

| Sealing | Requires precise sealing to prevent coolant leakage | No direct coolant sealing needed |

| Application | Used in heavy-duty and high-performance engines | Common in standard passenger car engines |

Introduction to Cylinder Liners

Cylinder liners are critical components in internal combustion engines, providing a durable surface for piston movement and ensuring optimal engine performance. Wet liners are directly exposed to coolant, allowing efficient heat dissipation and easier replacement, while dry liners fit into the engine block without coolant contact, offering higher structural support. Understanding these differences is essential for selecting appropriate liners based on engine design, cooling efficiency, and maintenance requirements.

Understanding Wet Liners

Wet liners are engine cylinder sleeves that rely on direct contact with coolant to efficiently dissipate heat, enhancing thermal management and engine performance. Unlike dry liners, which are surrounded by the engine block material, wet liners provide improved cooling and easier replacement, contributing to longer engine lifespan. Your choice of wet liners can significantly impact engine durability and maintenance efficiency in high-performance or heavy-duty applications.

Understanding Dry Liners

Dry liners are prefabricated panels made from gypsum plasterboard or similar materials, installed directly onto existing walls or partitions without the need for a wet plaster base. These liners offer quicker installation and reduced drying times compared to wet liners, making them cost-effective and ideal for renovations or new builds requiring speed. You can improve thermal insulation and soundproofing with dry liners, enhancing overall room comfort and energy efficiency.

Key Differences Between Wet and Dry Liners

Wet liners are engine cylinder liners that come into direct contact with the coolant, enhancing heat dissipation and maintaining optimal engine temperature, while dry liners are fitted into the engine block without direct coolant contact, relying on the block for heat transfer. Wet liners typically allow easier replacement and repair, offering better cooling efficiency, whereas dry liners provide increased cylinder bore stability and are commonly used in lightweight engine designs. The choice between wet and dry liners directly impacts engine durability, thermal management, and maintenance complexity.

Advantages of Wet Liners

Wet liners offer superior cooling efficiency by allowing direct contact between the coolant and the cylinder wall, which reduces engine overheating risks. They enable easier replacement or repair without removing the entire engine block, minimizing maintenance time and costs. Improved sealing and reduced cylinder distortion contribute to enhanced engine performance and longevity compared to dry liners.

Advantages of Dry Liners

Dry liners offer superior durability and easier installation compared to wet liners, making them ideal for rapid construction projects. They provide excellent insulation and soundproofing properties due to their solid, pre-fabricated panels, enhancing energy efficiency within your space. Maintenance is minimal because dry liners are less prone to cracking and moisture damage, ensuring long-term structural integrity.

Common Applications of Wet and Dry Liners

Wet liners are commonly used in high-performance diesel engines and heavy-duty industrial machinery where coolant circulation around the cylinder is critical for maintaining optimal operating temperatures. Dry liners find frequent applications in light-duty gasoline engines and motorcycles due to their ease of replacement and simpler engine design. Both liner types are essential in automotive and marine engines, but wet liners are preferred in environments requiring enhanced cooling efficiency.

Maintenance and Replacement Considerations

Wet liner engines require careful monitoring of coolant quality to prevent liner corrosion and ensure optimal sealing, as corrosion can lead to premature wear and replacement. Dry liner systems simplify maintenance by providing easier access for inspection and replacement without the need to drain the engine coolant, reducing downtime and associated costs. Your choice between wet and dry liners should consider the ease of maintenance and the potential frequency of replacement based on operating conditions and engine design.

Cost Implications: Wet Liner vs Dry Liner

Wet liners generally have higher initial costs due to the need for precise machining and coolant management systems, but they offer longer engine life and easier repairability, which can reduce long-term expenses. Dry liners tend to be less expensive upfront and simpler to replace but may lead to increased wear on the engine block, potentially raising maintenance costs over time. When considering your engine rebuild or manufacturing budget, weighing these cost implications between wet and dry liners is crucial for optimal financial planning.

Choosing the Right Liner for Your Engine

Selecting the right liner for your engine depends on factors such as durability, heat dissipation, and maintenance requirements. Wet liners offer superior cooling performance by being in direct contact with coolant, making them ideal for high-performance or heavy-duty engines. Dry liners, embedded within the engine block, provide structural strength and ease of replacement, suitable for standard or lower-stress applications where longevity and repairability are priorities.

Wet Liner vs Dry Liner Infographic

libmatt.com

libmatt.com