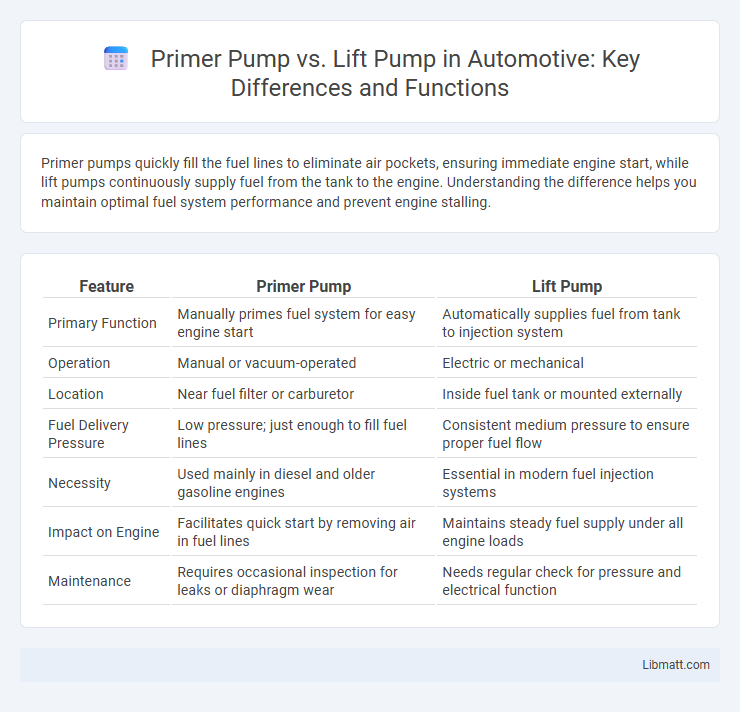

Primer pumps quickly fill the fuel lines to eliminate air pockets, ensuring immediate engine start, while lift pumps continuously supply fuel from the tank to the engine. Understanding the difference helps you maintain optimal fuel system performance and prevent engine stalling.

Table of Comparison

| Feature | Primer Pump | Lift Pump |

|---|---|---|

| Primary Function | Manually primes fuel system for easy engine start | Automatically supplies fuel from tank to injection system |

| Operation | Manual or vacuum-operated | Electric or mechanical |

| Location | Near fuel filter or carburetor | Inside fuel tank or mounted externally |

| Fuel Delivery Pressure | Low pressure; just enough to fill fuel lines | Consistent medium pressure to ensure proper fuel flow |

| Necessity | Used mainly in diesel and older gasoline engines | Essential in modern fuel injection systems |

| Impact on Engine | Facilitates quick start by removing air in fuel lines | Maintains steady fuel supply under all engine loads |

| Maintenance | Requires occasional inspection for leaks or diaphragm wear | Needs regular check for pressure and electrical function |

Understanding Primer Pumps: Definition and Function

Primer pumps are mechanical devices designed to remove air from the fuel system, ensuring a continuous and smooth flow of fuel to the engine. They create a vacuum that draws fuel from the tank, preventing air locks and facilitating faster engine start-up. Understanding the function of your primer pump can help maintain fuel system efficiency and prevent common issues in diesel or gasoline engines.

What is a Lift Pump? Key Features Explained

A lift pump is a mechanical or electric device designed to transfer fuel from the fuel tank to the engine's injection system, crucial for maintaining proper fuel pressure and flow. Key features of a lift pump include its ability to create consistent fuel delivery, reduce vapor lock by preventing fuel vaporization, and improve engine performance by ensuring a steady supply of fuel. Your vehicle's lift pump plays a vital role in optimizing engine efficiency and reliability, especially in diesel engines where precise fuel management is essential.

Primer Pump vs Lift Pump: Core Differences

Primer pumps are designed to manually evacuate air from fuel lines to ensure smooth engine starting, making them essential in diesel engines and marine applications. Lift pumps, on the other hand, are mechanical or electric pumps responsible for transferring fuel from the tank to the engine, maintaining consistent fuel pressure during operation. Understanding your engine's fuel delivery system helps determine whether a primer pump or lift pump is necessary for optimal performance.

Applications: Where Primer Pumps Are Used

Primer pumps are commonly used in automotive and marine applications to manually prime fuel systems, ensuring the engine receives fuel before starting. In agricultural equipment and heavy machinery, primer pumps help remove air from fuel lines, preventing engine hesitation and damage. Your equipment's smooth operation depends on the effective use of primer pumps in these critical fuel delivery tasks.

Typical Uses for Lift Pumps in Industry

Lift pumps are commonly used in the automotive and fuel industries to transfer fuel from the tank to the engine or fuel injection system, ensuring consistent flow and pressure. They are essential in industrial machinery for moving liquids like oil, water, or chemicals through pipelines and maintaining system efficiency. Your equipment benefits from lift pumps' reliable and continuous operation, particularly in applications requiring steady fluid delivery under varying pressure conditions.

Installation Requirements for Primer and Lift Pumps

Primer pumps require straightforward installation, typically mounted on the fuel line near the fuel tank to manually purge air and ensure proper fuel flow. Lift pumps demand more precise positioning, often installed between the fuel tank and injection system, with secure electrical connections and adherence to manufacturer specifications for pressure and flow rate. Proper installation of both pumps ensures reliable engine performance and prevents fuel delivery issues such as air locks or pressure drops.

Maintenance Considerations: Primer vs Lift Pumps

Maintenance considerations for primer pumps typically involve regular inspection of seals and diaphragms to prevent leaks and ensure proper pressure buildup, which is crucial for reliable engine starting. Lift pumps require frequent checking of fuel lines and filters to avoid clogging and maintain consistent fuel delivery, critical for engine performance and longevity. Understanding these distinct maintenance needs helps you optimize engine reliability and prevent costly repairs.

Performance Comparison: Efficiency and Reliability

Primer pumps deliver superior efficiency by quickly filling fuel lines, ensuring consistent pressure for smooth engine starts, while lift pumps maintain steady fuel flow but may respond slower during initial startup. Reliability favors primer pumps in applications requiring frequent restarts and precise fuel delivery, whereas lift pumps excel in continuous operation scenarios with less maintenance risk. Your choice depends on whether immediate fuel pressure or sustained fuel supply better suits your engine's operational needs.

Cost Implications: Primer Pump vs Lift Pump

Primer pumps typically have higher initial costs due to their more complex design and materials required for effective fuel priming, whereas lift pumps are generally more affordable and simpler in construction. Maintenance expenses for primer pumps can be greater over time because of added mechanical components prone to wear, while lift pumps often incur lower upkeep costs given their straightforward functionality. Evaluating total cost of ownership includes not only purchase price but also longevity, repair frequency, and compatibility with the fuel system.

Choosing the Right Pump for Your Application

Choosing the right pump depends on your specific needs: a primer pump is ideal for quickly removing air from fuel lines, ensuring smooth engine starting, while a lift pump is designed to continuously move fuel from the tank to the engine, providing consistent fuel flow under varying conditions. Your decision should consider factors such as fuel system design, engine type, and the necessity for reliable fuel delivery or initial priming. Proper selection optimizes engine performance and prevents potential fuel system issues.

Primer Pump vs Lift Pump Infographic

libmatt.com

libmatt.com