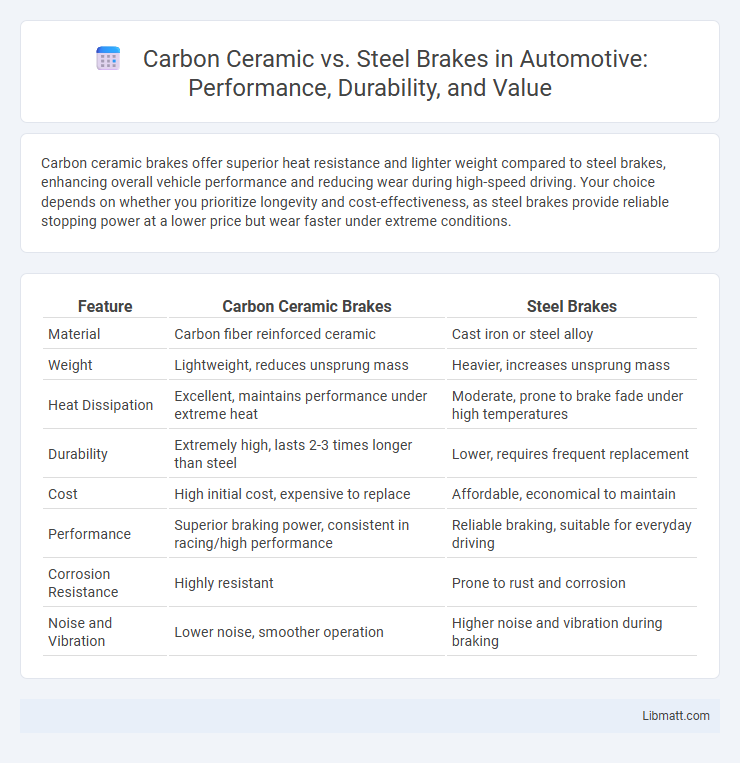

Carbon ceramic brakes offer superior heat resistance and lighter weight compared to steel brakes, enhancing overall vehicle performance and reducing wear during high-speed driving. Your choice depends on whether you prioritize longevity and cost-effectiveness, as steel brakes provide reliable stopping power at a lower price but wear faster under extreme conditions.

Table of Comparison

| Feature | Carbon Ceramic Brakes | Steel Brakes |

|---|---|---|

| Material | Carbon fiber reinforced ceramic | Cast iron or steel alloy |

| Weight | Lightweight, reduces unsprung mass | Heavier, increases unsprung mass |

| Heat Dissipation | Excellent, maintains performance under extreme heat | Moderate, prone to brake fade under high temperatures |

| Durability | Extremely high, lasts 2-3 times longer than steel | Lower, requires frequent replacement |

| Cost | High initial cost, expensive to replace | Affordable, economical to maintain |

| Performance | Superior braking power, consistent in racing/high performance | Reliable braking, suitable for everyday driving |

| Corrosion Resistance | Highly resistant | Prone to rust and corrosion |

| Noise and Vibration | Lower noise, smoother operation | Higher noise and vibration during braking |

Introduction to Carbon Ceramic and Steel Brakes

Carbon ceramic brakes utilize advanced composite materials combining carbon fibers with ceramic matrix, offering superior heat resistance, lighter weight, and exceptional durability compared to traditional steel brakes. Steel brakes, made from cast iron or stainless steel, provide reliable performance at a lower cost but tend to be heavier and more susceptible to fading under high temperatures. Your choice between these braking systems impacts vehicle performance, maintenance intervals, and overall driving experience.

Material Composition and Technology

Carbon ceramic brakes utilize advanced carbon-fiber reinforced ceramic composite materials, offering superior heat resistance, reduced weight, and enhanced durability compared to traditional steel brakes made from cast iron or steel alloys. The innovative matrix structure in carbon ceramic discs allows for better thermal conductivity and less brake fade under extreme conditions, improving braking performance and longevity. Your vehicle's braking system benefits from carbon ceramic technology through increased corrosion resistance and consistent stopping power, especially in high-performance or demanding driving environments.

Performance Differences: Braking Power and Fade

Carbon ceramic brakes exhibit superior braking power and significantly higher resistance to brake fade compared to steel brakes, maintaining consistent performance under extreme temperatures. The lightweight nature of carbon ceramic rotors reduces unsprung mass, enhancing overall vehicle handling and heat dissipation efficiency. Steel brakes, while more affordable and durable in everyday use, tend to experience quicker fade during prolonged aggressive braking due to lower thermal capacity.

Weight Comparison and Vehicle Dynamics

Carbon ceramic brakes weigh significantly less than steel brakes, reducing unsprung mass and rotational inertia for improved vehicle handling and responsiveness. This weight advantage enhances acceleration, braking performance, and cornering stability, providing a more dynamic driving experience. Your vehicle benefits from quicker suspension response and reduced strain on components, optimizing overall dynamics.

Durability and Lifespan

Carbon ceramic brakes boast exceptional durability and a longer lifespan compared to steel brakes, often lasting up to 100,000 miles under normal driving conditions. Unlike steel brakes, they resist wear and heat fade more effectively, maintaining consistent performance even under extreme stress. You'll benefit from reduced brake replacement frequency and lower long-term maintenance costs with carbon ceramic technology.

Maintenance Requirements and Costs

Carbon ceramic brakes require significantly less maintenance than steel brakes due to their high resistance to wear and heat, often lasting over 100,000 miles without replacement. Steel brakes, while cheaper upfront, experience faster wear, necessitating more frequent pad and rotor replacements that increase long-term costs. The initial investment for carbon ceramic brakes can be up to three times higher, but reduced maintenance and longer lifespan make them cost-effective for high-performance and luxury vehicles.

Applications: Road vs. Track Use

Carbon ceramic brakes excel in high-performance track applications due to their superior heat resistance, lighter weight, and consistent braking under extreme conditions. Steel brakes are preferred for road use as they offer better initial bite, lower cost, and reliable performance in varied weather conditions. While carbon ceramics provide longevity and reduced fade on the track, steel brakes deliver easier maintenance and effectiveness for everyday driving.

Environmental Impact and Sustainability

Carbon ceramic brakes offer a significant environmental advantage over steel brakes due to their longer lifespan and reduced wear particles, which lowers overall brake dust pollution. The manufacturing process of carbon ceramics consumes more energy but results in less frequent replacement and lower resource use over time, enhancing sustainability. Steel brakes, while cheaper and more recyclable, generate more particulate emissions and require more frequent production and disposal, increasing their environmental footprint.

Cost Analysis: Initial and Long-Term Investment

Carbon ceramic brakes demand a significantly higher initial investment, often costing two to three times more than traditional steel brakes, due to advanced manufacturing processes and premium materials. Over time, carbon ceramic brakes offer superior durability and heat resistance, reducing replacement frequency and maintenance costs, which can offset their upfront price in high-performance or frequent use scenarios. Your choice should consider both the upfront expense and the potential long-term savings based on driving style and vehicle usage to optimize cost-efficiency.

Choosing the Right Brakes for Your Driving Needs

Carbon ceramic brakes offer superior heat resistance, reduced weight, and longer lifespan, making them ideal for high-performance driving and track use. Steel brakes provide balanced performance with better cost efficiency and easier maintenance, suited for everyday commuting and moderate driving conditions. Selecting the right brakes depends on your driving style, vehicle type, and budget considerations to maximize safety and performance.

carbon ceramic vs steel brakes Infographic

libmatt.com

libmatt.com