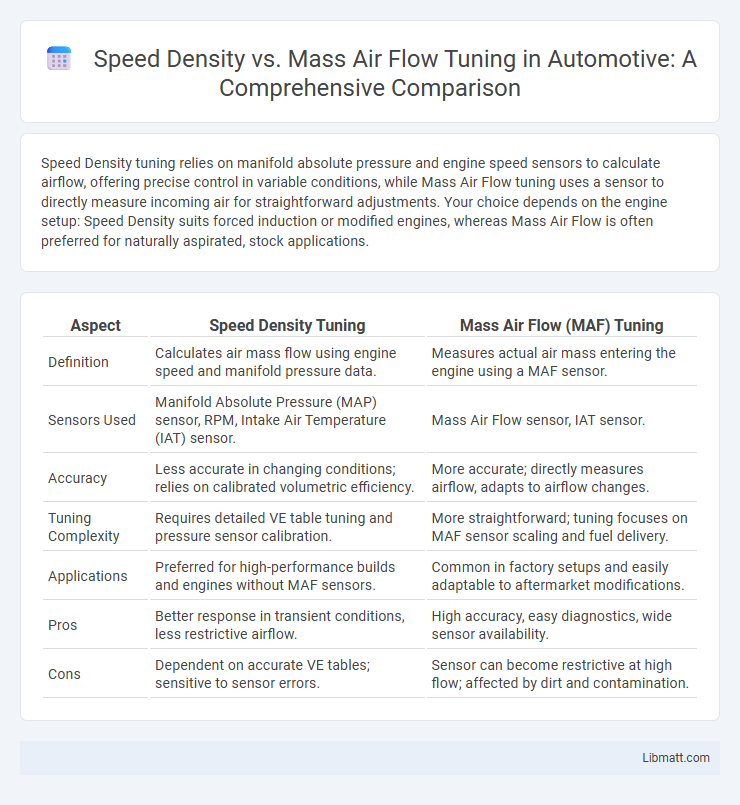

Speed Density tuning relies on manifold absolute pressure and engine speed sensors to calculate airflow, offering precise control in variable conditions, while Mass Air Flow tuning uses a sensor to directly measure incoming air for straightforward adjustments. Your choice depends on the engine setup: Speed Density suits forced induction or modified engines, whereas Mass Air Flow is often preferred for naturally aspirated, stock applications.

Table of Comparison

| Aspect | Speed Density Tuning | Mass Air Flow (MAF) Tuning |

|---|---|---|

| Definition | Calculates air mass flow using engine speed and manifold pressure data. | Measures actual air mass entering the engine using a MAF sensor. |

| Sensors Used | Manifold Absolute Pressure (MAP) sensor, RPM, Intake Air Temperature (IAT) sensor. | Mass Air Flow sensor, IAT sensor. |

| Accuracy | Less accurate in changing conditions; relies on calibrated volumetric efficiency. | More accurate; directly measures airflow, adapts to airflow changes. |

| Tuning Complexity | Requires detailed VE table tuning and pressure sensor calibration. | More straightforward; tuning focuses on MAF sensor scaling and fuel delivery. |

| Applications | Preferred for high-performance builds and engines without MAF sensors. | Common in factory setups and easily adaptable to aftermarket modifications. |

| Pros | Better response in transient conditions, less restrictive airflow. | High accuracy, easy diagnostics, wide sensor availability. |

| Cons | Dependent on accurate VE tables; sensitive to sensor errors. | Sensor can become restrictive at high flow; affected by dirt and contamination. |

Understanding Speed Density and Mass Air Flow Systems

Speed Density uses intake manifold pressure and engine RPM data to calculate air mass entering the engine, relying on sensors like MAP and IAT for real-time airflow estimation, making it highly adaptable for forced induction setups. Mass Air Flow tuning directly measures the volume and density of incoming air with an MAF sensor, providing precise air mass readings critical for accurate fuel delivery in naturally aspirated and moderate boost engines. Understanding these systems is essential for optimizing engine performance, as Speed Density offers flexibility in sensor choice while Mass Air Flow provides accurate, direct airflow measurement.

How Speed Density Tuning Works

Speed Density tuning calculates engine airflow based on manifold absolute pressure (MAP), intake air temperature (IAT), and engine speed (RPM) rather than using a direct air measurement. This method utilizes volumetric efficiency tables alongside manifold pressure data to estimate the amount of air entering the engine for fuel delivery. The result is a dynamic fuel map that adjusts fueling based on engine load and atmospheric conditions without relying on a mass air flow sensor.

Principles Behind Mass Air Flow Tuning

Mass Air Flow (MAF) tuning relies on measuring the incoming air volume and density using a MAF sensor to accurately calculate the engine's air intake, ensuring optimal fuel delivery and combustion. This method directly monitors the mass of air entering the engine, allowing precise fuel mapping adjustments based on real-time airflow data. By capturing variations in temperature, pressure, and humidity, MAF tuning enhances engine performance and efficiency compared to speed density tuning, which estimates airflow indirectly.

Key Differences Between Speed Density and MAF Tuning

Speed Density tuning relies on manifold absolute pressure (MAP) sensors combined with engine RPM and intake air temperature to estimate airflow, while Mass Air Flow (MAF) tuning measures the actual volume of air entering the engine directly through a MAF sensor. Speed Density systems require precise volumetric efficiency (VE) tables for accurate airflow calculations, whereas MAF tuning adjusts fuel delivery based on real-time airflow measurements, often resulting in more straightforward tuning with fewer adjustments. Your choice between these methods impacts tuning complexity, sensor dependency, and responsiveness to modifications like forced induction or intake changes.

Advantages of Speed Density Tuning

Speed Density tuning offers precise control over air-fuel ratio by calculating airflow based on engine speed and manifold absolute pressure, eliminating the need for a physical airflow meter. This method enhances responsiveness and accuracy in varying conditions, especially in forced induction setups where airflow sensors can be less reliable. Speed Density tuning also simplifies sensor dependencies, providing consistency and reliability for performance optimization and troubleshooting.

Benefits of Mass Air Flow Tuning

Mass Air Flow (MAF) tuning provides precise real-time measurement of the actual amount of air entering the engine, enhancing fuel injection accuracy and improving overall engine performance. This method adapts seamlessly to varying air densities and environmental conditions, reducing the risk of air-fuel ratio errors compared to speed density tuning. With MAF tuning, drivers experience better throttle response, increased fuel efficiency, and reduced emissions due to optimized air intake data.

Common Applications and Use Cases

Speed Density tuning is commonly used in older vehicles with simpler engine management systems or in motorsports where precise control over air-fuel mixture is critical without relying on mass airflow sensor data. Mass Air Flow (MAF) tuning finds frequent application in modern vehicles equipped with MAF sensors, providing accurate measurement of incoming air for improved fuel efficiency and emissions control. Custom performance builds often switch between these methods based on sensor availability, desired responsiveness, and tuning flexibility.

Tuning Challenges and Limitations

Speed Density tuning faces challenges like sensor accuracy dependence and difficulty adapting to dynamic engine conditions, often requiring precise intake air temperature and manifold pressure calibration. Mass Air Flow (MAF) tuning, while generally more straightforward due to direct airflow measurement, struggles with sensor contamination and airflow sensor limitations at extreme engine loads or modifications. Both methods encounter limitations in accurately correcting fueling for transient throttle events, making hybrid systems or advanced sensor fusion increasingly important for optimal engine tuning.

Choosing the Right System for Your Vehicle

Selecting the right tuning system between Speed Density and Mass Air Flow (MAF) depends on your vehicle's specific airflow measurement needs and modifications. Speed Density tuning calculates airflow using manifold pressure and intake air temperature sensors, ideal for highly modified engines with greater airflow variability. MAF tuning measures actual airflow directly with a sensor, providing more precise fuel control for stock or mildly modified vehicles with consistent airflow patterns.

Future Trends in Engine Management Tuning

Speed Density and Mass Air Flow tuning continue evolving with advances in engine management systems that integrate AI-driven adaptive algorithms and real-time sensor fusion for enhanced accuracy. Emerging trends highlight the growing adoption of machine learning models that optimize fuel delivery and ignition timing by analyzing transient load conditions and combustion efficiency metrics. Your tuning strategy will increasingly leverage cloud-based data analytics and digital twins to predict engine behavior, enabling precise control for performance and emissions compliance.

Speed Density vs Mass Air Flow Tuning Infographic

libmatt.com

libmatt.com