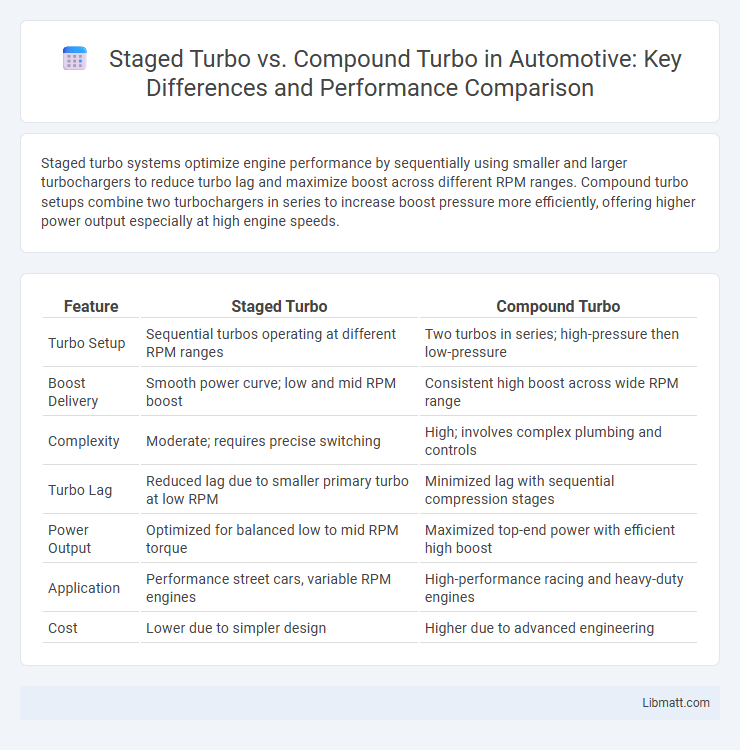

Staged turbo systems optimize engine performance by sequentially using smaller and larger turbochargers to reduce turbo lag and maximize boost across different RPM ranges. Compound turbo setups combine two turbochargers in series to increase boost pressure more efficiently, offering higher power output especially at high engine speeds.

Table of Comparison

| Feature | Staged Turbo | Compound Turbo |

|---|---|---|

| Turbo Setup | Sequential turbos operating at different RPM ranges | Two turbos in series; high-pressure then low-pressure |

| Boost Delivery | Smooth power curve; low and mid RPM boost | Consistent high boost across wide RPM range |

| Complexity | Moderate; requires precise switching | High; involves complex plumbing and controls |

| Turbo Lag | Reduced lag due to smaller primary turbo at low RPM | Minimized lag with sequential compression stages |

| Power Output | Optimized for balanced low to mid RPM torque | Maximized top-end power with efficient high boost |

| Application | Performance street cars, variable RPM engines | High-performance racing and heavy-duty engines |

| Cost | Lower due to simpler design | Higher due to advanced engineering |

Introduction to Turbocharging: Staged vs Compound

Staged turbocharging uses multiple turbochargers operating sequentially, where a smaller turbo boosts low RPM performance and a larger one enhances high RPM power. Compound turbocharging involves two turbos working in series on the same exhaust flow, compressing air in stages to deliver higher overall boost pressure. Both methods improve engine efficiency and power, but staged setups optimize responsiveness across the RPM range, while compound systems maximize peak boost for ultimate performance.

What Is a Staged Turbo System?

A staged turbo system utilizes two differently sized turbochargers operating sequentially to optimize boost pressure across the engine's RPM range, with a smaller turbo providing quick spool-up at low RPMs and a larger turbo delivering high boost at higher RPMs. This setup improves overall engine performance by reducing turbo lag and increasing power efficiency. Staged turbos function by switching between the turbos or combining their outputs based on engine load, enhancing responsiveness and maximizing power output.

Understanding Compound Turbo Setups

Compound turbo setups combine two turbochargers of different sizes to maximize engine efficiency and power across a wider RPM range. Unlike staged turbos, which operate one turbo at low RPMs and switch to a larger one at high RPMs, compound turbos work simultaneously, with the smaller turbo feeding compressed air into the larger turbo for boosted performance. Understanding how your engine benefits from compound turbo setups allows you to optimize boost pressure, reduce turbo lag, and achieve smoother power delivery.

Key Differences Between Staged and Compound Turbos

Staged turbos operate sequentially with smaller and larger turbos activating at different RPM ranges, providing a broader power band and improved low-end torque. Compound turbos use one turbo to compress air before feeding it into a larger turbo, maximizing high-end power through increased overall boost pressure. Your choice depends on desired power delivery, with staged setups favoring versatility and compound systems excelling in peak performance.

Performance Benefits of Staged Turbo Systems

Staged turbo systems deliver superior performance by optimizing boost pressure across a wider RPM range, enhancing low-end torque without sacrificing top-end power. This setup allows your engine to maintain efficient airflow and reduce turbo lag compared to single or compound turbo configurations. As a result, you experience smoother acceleration and improved overall engine responsiveness, making staged turbos ideal for high-performance applications.

Power Delivery and Efficiency in Compound Turbos

Compound turbo systems combine a high-pressure and a low-pressure turbo to optimize power delivery by reducing turbo lag and providing a wider power band compared to staged turbos. This setup allows your engine to maintain higher efficiency under varying load conditions by leveraging the low-pressure turbo for low RPM performance and the high-pressure turbo for peak power, resulting in smoother acceleration and improved fuel economy. The efficient airflow management in compound turbos enhances overall engine responsiveness and power output, making them ideal for performance-oriented applications.

Installation Complexity and Maintenance Comparison

Staged turbos involve installing two turbochargers in sequence, typically requiring precise tuning and more complex piping, leading to higher installation complexity compared to compound turbos, which integrate two turbines on a single shaft, simplifying the setup. Maintenance for staged turbos can be more demanding due to the need to service two separate units, whereas compound turbos generally require less upkeep since the components work as a single, unified system. Your choice between staged and compound turbo setups will impact the ease of installation and long-term maintenance based on the vehicle's design and intended performance goals.

Ideal Applications: Staged Turbo vs Compound Turbo

Staged turbo systems are ideal for passenger vehicles and light trucks where smooth power delivery across a wide RPM range is essential, optimizing response and efficiency for everyday driving and moderate performance needs. Compound turbo setups excel in heavy-duty applications such as race cars, large commercial trucks, or industrial machinery where maximizing peak power and boosting efficiency under high-load conditions is critical. Your choice between these turbos should consider the vehicle's primary use, expected power demand, and engine characteristics to match the turbo system that best supports your performance goals.

Cost Considerations and Budgeting

Staged turbo systems generally require a lower initial investment compared to compound turbo systems due to simpler design and fewer components, making them more budget-friendly for moderate performance enhancements. Compound turbo setups involve higher costs from complex engineering, additional hardware, and precision tuning, demanding a larger budget for installation and maintenance. When budgeting, consider not only upfront expenses but also long-term reliability and potential repair costs associated with the increased mechanical complexity of compound turbos.

Which Turbo System Is Best for Your Build?

Staged turbo systems utilize multiple turbos operating at different RPM ranges to deliver a balanced power curve, making them ideal for street performance with minimal turbo lag. Compound turbo setups employ two turchargers in series to achieve higher boost pressures and increased overall efficiency, favored in high-performance or racing builds requiring maximum power. Choosing the best turbo system depends on your engine configuration, desired powerband, and the specific goals of your build, with staged turbos excelling in drivability and compound turbos in peak performance.

staged turbo vs compound turbo Infographic

libmatt.com

libmatt.com